English

Air cooled water chillers and air-to-water reverse cycle heat pumps

Installation and maintenance manual

IOM AQLH-N.2GB

Date : November 2005

Supersedes : IOM 02 AQL-AQH.1GBF-N/10.02

AQL/AQH 20 ÷ 130

20

131 kW

23

141 kW

English

Page 1

1 MANUFACTURER INFORMATION

1.1 Preface 3

1.2 Warranty 3

1.3 Safety 3

1.4 Emergency Stop 4

1.5. Information about this Manual 4

1.6 Safety Labels 5

1.7. Material Safety Data 6

2 PRODUCT DESCRIPTION

2.1 General Information 9

2.2 Accessories 10

2.3 Refrigeration Circuits 12

3 TRANSPORTATION, HANDLING

AND STORAGE

3.1 Inspection 16

3.2 Handling 16

3.3 Storage 17

4 INSTALLATION

4.1 Installation Site 18

4.2 Defrost Water Drainage

(only for AQH units) 18

4.3 Installation of Spring

Shock Absorbers 19

4.4 External Water Circuit 20

4.5 Water connections 21

4.6 Accumulation Tank Kit 22

4.7 Electrical Supply Features 27

4.8 Electrical Connections 27

5 COMMISSIONING

5.1 Preliminary Checks 32

5.2 Starting 32

5.3 Performance Check 33

5.4 Delivery to the User 33

6 AQL/AQH CONTROL

6.1 Electronic Card Control 34

6.2 Dip Switches 35

6.3 ALAr and LOg Menu 37

6.4 SEnS Menu –Sensor reading 37

7 MAINTENANCE

7.1 General Information 38

7.2. Daily Maintenance 38

7.3 Refrigerant Charge 39

7.4 Compressors 39

7.5 Refrigerant/Air Exchangers 39

7.6 Fans of the Refrigerant/

Air Exchangers 39

7.7 Dryer Filter 39

7.8 Sight Glass 40

7.9 Thermal Expansion Valves 40

7.10 Refrigerant / Circulating

Fluid Exchanger 40

8 TROUBLE SHOOTING 41

Index

Index

9 TECHNICAL DATA

9.1 Hydraulic Features 43

9.2 Working Range 46

9.3. Safety Devices 47

9.4. Noise Levels 47

9.5 General Characteristics 48

9.6 Electrical Characteristics 50

9.7 Dimensional Data 52

9.8 Space Requirements 58

10 SPARE PARTS

10.1 Recommended Spare Parts 60

10.2 Oils Recommended for Compressors 60

10.3 Relevant Wiring Diagrams 60

11 DISMANTLING, DEMOLITION

AND SCRAPPING

11.1 General Information 61

Page 2

Index

The warranty will be only valid if the following re-

quirements are met:

h

The initial start-up shall be carried out by the per-

sonnel from an Authorised Service Centre.

h

Maintenance may be only carried out by duly

trained personnel.

h

Only original spare parts have been used.

h

All the scheduled maintenance operations de-

tailed in this manual have been performed.

If no water filter is installed in the external

circuit, this will automatically make the war-

ranty null and void. The Hydro Kit option

which shall be mounted on the field already

includes such a filter.

The failure to comply with any of the conditions

above will automatically make the warranty of the

unit null and void.

1.3 Safety

The installation of these units shall be car-

ried out according to the Machinery Safety

Directive (98/37/EC), the 72/23 EEC Low

Voltage Directive the 89/336/EEC Electro-

magnetic Interference Directive as well as

in compliance with other rules in force in

the country where the installation is carried

out. Do not operate the unit if what above

has not been observed.

The unit shall be earthed. Installa-

tion and/or maintenance opera-

tions may be only performed after

having powered off the electrical

panel of the unit.

The non-observance of the safety measures above

may result in electrocution and fire risks in case of a

short-circuit.

1 MANUFACTURER INFORMATION

1.1 Preface

The Itelco-Clima AQL/AQH units are manufactured

according to the most stringent design and construc-

tion standards to ensure the highest performance, re-

liability and adaptability level to all types of air con-

ditioning installations. These units are intended to

cool water or glycol/water (and to heat water in the

case of heat pump models). They are not suitable for

purposes other than those specified in this manual.

If the Hydro Kit option (hydronic module) is mounted

on the field, these units can be converted into a com-

plete and compact cooling and heating system for

production and distribution.

If these units are used improperly or for purposes oth-

er than those for which they have been designed

without Itelco-Clima prior consent, they might prove

to be dangerous.

This manual contains all the information required for

the correct installation and start-up of the unit as well

as all operation and maintenance instructions. This

manual should be carefully read before attempting

to operate or service the unit.

With the exception of the operations specifically de-

tailed in this manual, all installation, commissioning

and maintenance tasks may be only performed by

duly trained and qualified personnel from a Service

Centre.

The manufacturer is not liable for any damage which

may be caused to things or people as a result of in-

correct installation, commissioning and/or operation

of the unit and/or failure to follow the procedures

and instructions contained in this manual.

1.2 Warranty

This unit is supplied finished, tested and ready to

work.

Any warranty will be automatically made null and

void if the device has been modified without the

manufacturer’s prior written consent.

English

Manufacturer information

Page 3

This unit contains liquid and

gaseous refrigerant under pressure

inside heat exchangers, compres-

sors and refrigerating lines. The re-

lease of this refrigerant may be

dangerous and cause injury.

Fan protections shall always be fit-

ted and not removed unless the de-

vice has been powered off.

It is the user’s responsibility to en-

sure that the unit is suitable for its

conditions of use and that the in-

stallation and maintenance are car-

ried out only by the personnel who

have the experience required to act

as instructed by this manual.

The unit shall be supported by a

bedplate which shall have the fea-

tures specified by this manual. Fail-

ure to provide proper support may

put the personnel at risk of serious

injur.

The unit has not been designed to support

any load and/or stress which might derive

from adjacent units, pipelines and/or struc-

tures. Any external load or stress may cause

the structure of the unit to break or collapse

as well as represent a serious danger for

people. In these cases, any form of warran-

ty will automatically become null and void.

The packaging material shall be neither dis-

carded nor burnt in the environment.

1.4. Emergency Stop

The switch outside the unit is set to 0 (Off) to cause

the unit to stop.

After having acted on this switch, the unit shall be

restarted in accordance with the procedure detailed

in this manual.

Manufacturer information

1.5.

Information about this Manual

The instructions contained in this manual shall be

strictly followed for safety reasons. Otherwise, any

damage will not be covered by the manufacturer’s

warranty.

The following conventional symbols are used by this

manual in case of potential dangers:

The Danger symbol is used to alert

you to procedures or practices

which, if not correctly followed,

might cause serious personal injury.

The Attention symbol will appear before

procedures which, if not observed, might

result in damage to the unit.

The Note symbol will draw the user’s atten-

tion to comments which are particularly im-

portant with respect to the rest of the text.

The content of this manual and of any other docu-

ment supplied with the unit is the exclusive property

of the manufacturer who reserves any property right.

Its reproduction is forbidden without the prior written

consent by the manufacturer or its legal representa-

tive.

Page 4

English

Manufacturer information

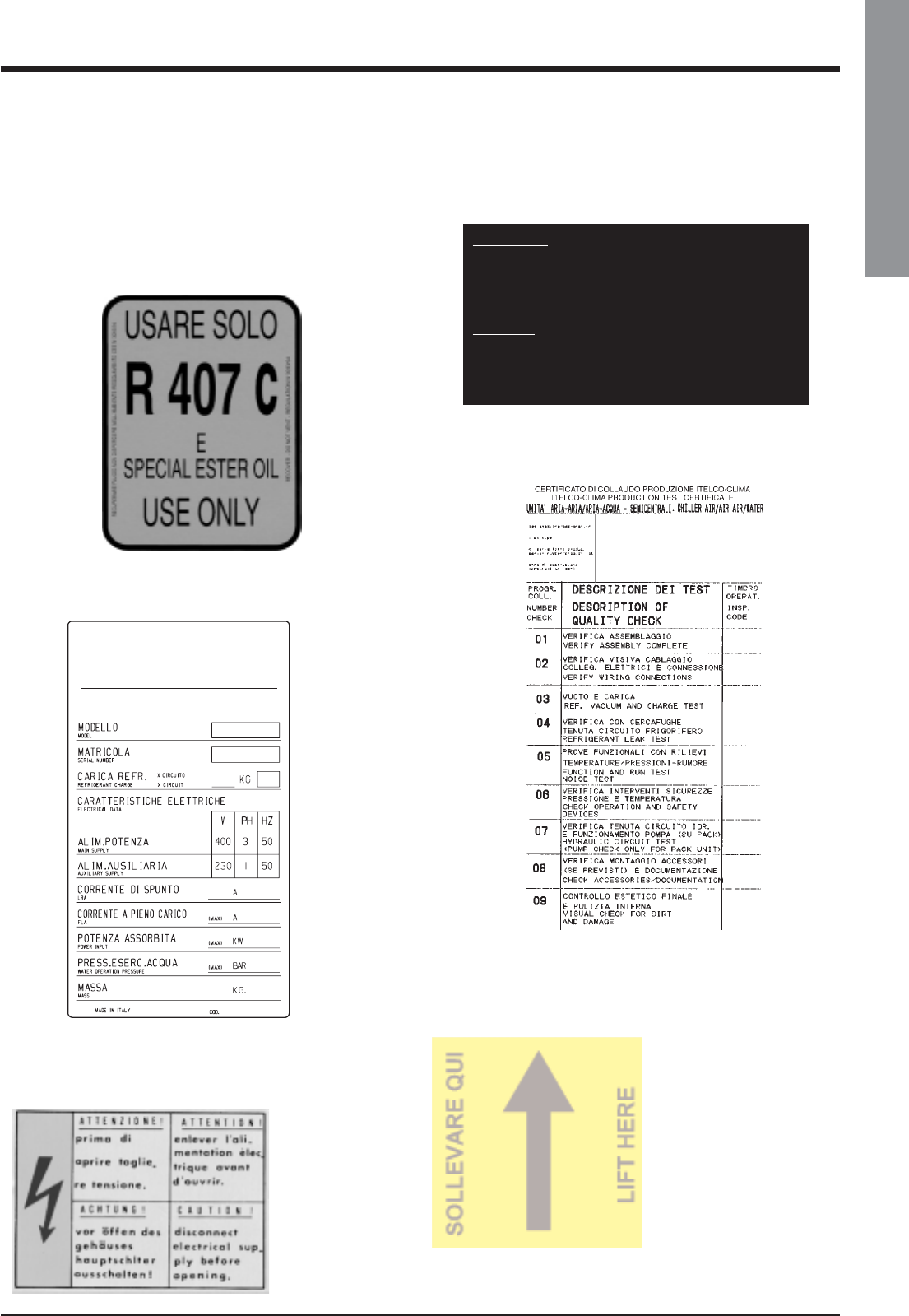

1.6 Safety Labels

The following labels are fitted to each unit in their

proper locations:

Compressor Oil Heater Warning Label

(Outside the door of the electrical panel)

Page 5

Refrigerant Identification Label

(Outside the panel door)

Electrical Warning Label

(Adjacent to the main switch)

Test Certificate

(Inside the door of the external panel)

Plate showing the lifting point

ATTENZIONE

INSERIRE LE RESISTENZE DI RISCALDAMENTO OLIO ALMENO

12 ORE PRIMA DI OGNI AVVIAMENTO.

PRIMA DELLA MESSA IN TENSIONE ASSICURARSI CHE LE VITI

DEI CIRCUITI ELETTRICI SIANO SERRATE COMPLETAMENTE.

WARNING

ENERGIZE THE CRANCKCASE HEATER FOR AT LEAST 12

HOURS BEFORE EACH STARTING.

BEFORE TIGHTENING-UP, TO TIGHTEN ALL TERMINAL SCREWS

ESPECIALLY THOSE IN MAIN CIRCUIT.

881000215/B

Unit Identification Label

(Inside the door of the external panel)

Manufacturer information

Page 6

1.7. Material Safety Data

Refrigerant Data

Safety Data

Toxicity

In contact with skin

In contact with eyes

Ingestion

Inhalation

Further Medical Advice

Long-term exposure

Occupational exposure limits

Stability

Conditions to avoid

Hazardous reactions

Hazardous decomposition products

General precautions

R407C

Low

Liquid splashes or sprays may cause freeze burns. Unlikely to be hazardous by skin absorption.

However, R407C may be slightly irritant and, if liquid, it has a strong degreasing effect. Flush conta-

minated skin areas with running water. If it comes into contact with wet fabrics, the liquid refrigerant

will cause them to freeze and adhere to the skin. Carefully remove the contaminated clothing since it

might adhere to the skin and cause freeze burns. Apply to a doctor if the affected skin areas should

be reddened or irritated.

Vapours have no effect. Liquid splashes or sprays may cause freeze burns. In these cases rinse your

eyes with running water or with a solution for eye lavages for at least 10 minutes. Immediately apply to

a doctor.

Very unlikely to occur. If this should be the case, it may cause freeze burns. Never induce vomit-

ing. Keep the patient awake. Make it rinse its mouth with running water and make it drink about

1/4 of a litre. Immediately apply to a doctor.

At high concentrations there is a danger of asphyxia due to a reduced oxygen content in the

atmosphere. In these cases take the patient to the open air, in a cool place and keep it at rest.

Administer oxygen, if required. Apply artificial respiration if breathing has ceased or if it has

become irregular. In case of heart failure immediately apply cardiac massage. Immediately

apply to a doctor.

A symptomatic and supportive therapy is generally suitable. A heart sensitisation has been

observed in some cases, as a result of exposures to particularly high concentrations. In the pres-

ence of catecholamines (such as for example adrenaline) in the blood flow, it has increased the

irregularity of the cardiac rhythm and then caused the heart failure.

Use in the presence of exposed flames, red heat surfaces and high humidity levels.

Possibility of violent reactions with sodium, potassium, barium and other alkaline substances.

Incompatible materials: magnesium and all the alloys containing over 2% of magnesium.

Avoid the inhalation of high concentrations of vapours. The concentration in the atmosphere

shall be kept at the minimum value and anyway below the occupational limits. Since vapours

are heavier than air and they tend to stagnate and to build up in closed areas, any opening for

ventilation shall be made at the lowest level.

R407C: A lifetime study which has been conducted on the effects inhalation may have on rats at

50,000 ppm has shown the onset of benign tumours of the testicle. These remarks suggest that

there is no danger for human beings if they are exposed to concentrations below the occupa-

tional limits or equal to them.

R407C: Recommended limits: 1,000 ppm v/v – 8 hours TWA.

R407C: Not specified.

R407 C: Halogen acids deriving from thermal decomposition and hydrolysis.

R407C: High concentration levels of its vapours in the air can produce an anaesthetic effect,

including the loss of consciousness. Particularly severe exposures may cause heart arrhythmia

and sometimes prove to be also fatal.

English

Manufacturer information

Page 7

Breathing protection

Storage

Preservation

Protection clothes

Behaviour in case of leaks or escapes

Disposal

Combustibility features

Behaviour in case of fire

Containers

In case of doubt about the actual concentration, wear breathing apparatus. It should be self-con-

tained and approved by the bodies for safety protection.

Refrigerant containers shall be stored in a cool place, away from fire risk, direct sunlight and all

heat sources, such as radiators. The maximum temperature shall never exceed 45°C in the stor-

age place.

Wear boots, safety gloves and glasses or masks for facial protection.

Never forget to wear protection clothes and breathing apparatus. Isolate the source of the leak-

age, provided that this operation may be performed in safety conditions. Any small quantity of

refrigerant which may have escaped in its liquid state may evaporate provided that the room is

well ventilated.In case of a large leakage, ventilate the room immediately. Stop the leakage with

sand, earth or any suitable absorbing material. Prevent the liquid refrigerant from flowing into

drains, sewers, foundations or absorbing wells since its vapours may create an asphyxiating at-

mosphere.

The best procedure involves recovery and recycle. If this is not possible, the refrigerant shall be

given to a plant which is well equipped to destroy and neutralise any acid and toxic by-product

which may derive from its disposal.

In case of fire wear protection clothes and self-contained breathing apparatus.

If they are exposed to the fire, they shall be constantly cooled down by water sprays.

Containers may explode if they are overheated.

R407C: Non flammable in the atmosphere.

Manufacturer information

Page 8

Lubricating Oil Data

Safety Data

Classification

In contact with skin

In contact with eyes

Ingestion

Inhalation

Conditions to avoid

Breathing protection

Protection clothes

Behaviour in case of leaks or escapes

Disposal

Behaviour in case of fire

Containers

Behaviour in case of fire

Oil

R407C: ICI EMKARATE RL32CF

MOBIL EAL ARTIC 22CC

Not dangerous.

Very little irritating. No first aid is required. it is enough to provide for a reasonable personal hy-

giene, i.e. washing the exposed skin areas with water and soap several times a day. Wash

dirty work clothes at least once a week.

Flush your eyes with a eyewash solution for at least 15 minutes and apply to a doctor.

Immediately apply to a doctor.

Immediately apply to a doctor.

Contact with strongly oxidising agents, alkaline or acid solutions as well as overheating. It may

degrade some types of paint and rubber.

It may only be used in well ventilated areas.

Always wear glasses or a mask for facial protection. Even if it is not strictly necessary, it is rec-

ommended to wear gloves in case of a long-term exposure.

Wear protection clothes and gloves. Stop the leakage. Absorb oil by using suitable substances,

such as sand, sawdust and any other material available on the market.

Oil and whatever may be contaminated by it shall be incinerated in a plant in compliance with

the local standards about the destruction of exhausted oils.

Use dry chemical compounds, carbon dioxide or extinguishing foams to put out the fire. The use

of water on hot oil which has been set on fire may cause splashing.

If oil has not caught fire yet, spray some water to disperse the vapours and protect the personnel

who are attempting to stop the leakage.

If they are exposed to the fire, they shall be constantly cooled down by water sprays.

In case of fire wear self-contained breathing apparatus.

English

Product Description

2 PRODUCT DESCRIPTION

2.1 General Information

AQL/AQH units are of an enbloc type with one sin-

gle refrigerating circuit. They are intended to cool

down the water required for any air-conditioning ap-

plication as well as any other fluid, such as for exam-

ple glycol water.

These units are completely assembled at works. They

are equipped with all the refrigerating connections

and the internal electrical wiring required for a rapid

installation on the field.

An operation test is performed after assembly, with

water flowing through the refrigerant/water ex-

changer in order to make sure that every refrigerat-

ing circuit is properly working. The refrigerating cir-

cuits of every unit are pressure tested before inspec-

tion, drained and charged with R407C.

A low noise level is the result of a careful study. It is

achieved on chillers by using technologically ad-

vanced components: SCROLL compressors with

soundproof cases and fans with streamline nozzles.

All this without negatively affecting the operation

performances and limits of the units.

AQL models can cool down chilled water at a tem-

perature between + 18 and + 5°C.

AQH heat pump models can warm up water at a

temperature between 25°C and 50°C.

Body and Frame

The base and frame of these units are made with

very thick galvanized steel elements, assembled with

stainless steel screws. All panels can be disassem-

bled to ensure easy access to internal components.

All galvanized steel parts are protected by epoxy

powder paint.

Compressors

The models are equipped with two SCROLL airtight

tandem compressors with an internal motor protec-

tion and a separate soundproof coverage.

The compressors of all models are assembled on rub-

ber shock absorbers. Their motors can be directly

started. They are cooled down by the aspirated re-

frigerant gas and equipped with internal thermistor

protections against overloads.

Overload protections are automatically reset after

having tripped. The compressor terminal box has an

IP54 protection degree (AQL/AQH 40-130).

Compressors are powered on and off by the micro-

processor of the unit control system which is intended

to control the delivery of the thermal refrigerating ca-

pacity.

Evaporators

Evaporators are made up of stainless steel plates.

They are thermally insulated by means of a thick flex-

ible insulating mattress with closed cells. The maxi-

Page 9

Product Description

mum operating pressures correspond to 10 bar for

the water side and to 30 bar for the refrigerant side.

Antifreeze protection for the water in the exchangers

is ensured by electrical heaters and differential pres-

sure switches for 30 units and by flow switches for

the other units. The water side of these exchangers is

connected by manifolds which will provide for the

connection to the plant by means of one single gas

threaded attachment.

Condensing batteries

The batteries forming the condenser are made up of

copper tubes arranged in staggered rows and me-

chanically expanded inside an aluminium finned

pack.

The maximum operating pressure on the refrigerant

side of the condensing batteries will correspond to

28 bar.

Condenser Fans

The condenser fans are of a helical type. They are di-

rectly coupled and have an impeller with wing con-

toured aluminium blades. Each fan is equipped with

a galvanised steel accident-prevention protection

which is painted after manufacture. The fans motors

are completely closed. They have an IP54 protection

degree and a protection thermostat embedded in the

windings.

Fans Control

All models have a step speed controller as a stan-

dard. It will act according to the condensing pres-

sure and allow the operation up to an external oper-

ation of –5/10°C

Refrigerating Circuits

Each unit is equipped with a single refrigerating cir-

cuit of external service valves intended to measure

the refrigerant pressure and charge, a sight glass

with a humidity indicator, a dryer filter and a thermal

expansion valve.

Refrigerating circuits are also complete with a high

pressure switch as well as a high and low transduc-

er.

Control Supply Panel

All components of the control system and those nec-

essary to start the motors are shop connected and

tested. In 40-130 models, the components of the con-

trol system and of the supply system are accessible

through separate doors, while in 20-25-30-35 mod-

els the board is protected by a door which can be re-

moved with a screwdriver. The control compartment

contains an electronic card and a control board with

keyboard and display, to show the operational func-

tions, as well as the intervention of the alarms and

the working blocks.

2.2 Accessories

Water Filter

In 20-35 units, the 1-1/2” filter is included in the sup-

plied equipment; in 40-130 units (in the model

equipped with a pump) the filter is positioned in the

hydraulic circuit, while in the models without pump it

is supplied as an optional.

Anti-Vibration Kit

For 20-35 units, the anti-vibration kit made of special

rubber is provided together with the unit. As for 40-

130 models, the kit includes 4 spring shock-ab-

sorbers, to be mounted during the installation of the

unit by the customer.

Electrical flow switch or Water Differential

Pressure Switch

Models 20-35: differential pressure switch.

Models 40-130: electrical flow switch.

Corrosion proofing protection

for condensing batteries

Two-level optional treatment

I) Simple treatment for a non extreme application

II) Treatment for an extreme blygold application.

Intrusion proofing protection

for condensing batteries

A galvanised and painted steel wire net protection is

assembled outside the unit.

Water Gauge

It is assembled on the unit as a standard.

Pump

Double pump kit (Mod. 40-130)

Standard pump with head >10m H

2

O

High Pressure Fans (high head)

For 40-130 units, channeled fans with static pressure

80 Pa (models 40-60) and 100 Pa (models 70-130).

3-Wire Supply Kit

For 40-80 units, 3-phase supply without neutral wire

(for 90-130 units, supply without standard neutral

wire).

Page 10

Low temperature kit –18 °C (40-130)

Phase Monitor Kit (40-130)

Kit for shipping by plane

Complete wooden package with a unit without re-

frigerant and with a nitrogen precharge.

No CE declaration is supplied by the manufacturer

in this case (the unit is entirely tested at works).

Hydro Module

The hydro module is available for the units with a

pump. It is installed beneath the unit through the pipe

fittings which are supplied with the unit.

The module is entirely enclosed in a RAL 9001 gal-

vanised and painted steel body. The tank is com-

pletely insulated with 30 Kg/m

3

closed cell polyethyl-

ene in a silver colour.

Antifreeze resistances or a heating booster kit are in-

stalled in the tank (upon request).

On/Off Remote Kit

It enables the operator to power on the unit when it is

in standby mode, to display alarms and to switch

over cooling – heat pump. The kit will include a 3

metre long cable for installation on the wall.i.

Sequencer kit - 4 units

Kit of external pressure gauge

Cooling mode

The low pressure liquid refrigerant will flow into the

evaporator where it is evaporated and overheated

by the heat absorbed from the chilled water flowing

through the plates.

The low pressure steam produced as a result of this

process will enter the compressor where it is over-

pressurised and overheated. After having left the

compressor, the high pressure steam will enter the

condensing battery which will absorb its heat and re-

lease it to air circulating outside.

After having been properly liquefied and subcooled,

the refrigerant will go through the expansion valve

where its pressure and temperature are reduced be-

fore flowing into the evaporator where the cycle will

start again.

Page 11

Product Description

English

Page 12

Product Description

2.3 Refrigeration Circuits

Units AQL 20-80

OIL EQUALIZER

Components:

1 Compressors C1/C2

2 Condenser

3 Dehydrating filter

4 Liquid lamp

5 Expansion valve

6 Plate-type exchanger

7 Safety valve (only for units 40-80)

Safety & Control Devices:

CPT High-pressure service outlet

DIS Outlet temperature probe

EPT Low-pressure service outlet

EWT Entering water temperature probe

FH1 Pressure switch

FPC Condensing pressure transducer

FPE Evaporation pressure transducer

LWT Leaving water temperature probe

P Differential pressure switch, water side (only for units 20-35)

FS Electrical flow switch (optional, for units 20-35)

WATER

COLLECTOR

Page 13

Product Description

English

WATER

COLLECTOR

OIL EQUALIZER

Units AQL 90-130

Safety & Control Devices:

CPT High-pressure service outlet

DIS Outlet temperature probe

EPT Low-pressure service outlet

EWT Entering water temperature probe

FH Pressure switch

FPC Condensing pressure transducer

FPE Evaporation pressure transducer

LWT Leaving water temperature probe

FS Electrical flow switch

Components:

1 Compressors C1/C2

2 Condenser

3 Dehydrating filter

4 Liquid lamp

5 Expansion valve

6 Plate-type exchanger

7 Silencer

8 Ball cock

Page 14

Product Description

WATER

COLLECTOR

OIL EQUALIZER

Components:

1 Compressors C1/C2

2 Air exchanger

3 Dehydrating filter

4 Liquid lamp

5 Thermostatic expansion valve

6 Plate-type exchanger

7 4-way valve

8 Liquid receiver

9 Check valve

10 Safety valve (only for units 40-80)

Safety & Control Devices:

CPT High-pressure service outlet

DIS Outlet temperature probe

EPT Low-pressure service outlet

EWT Entering water temperature probe

FH1 Pressure switch

FPC Condensing pressure transducer

FPE Evaporation pressure transducer

LWT Leaving water temperature probe

P Differential pressure switch, water side (only for units 20-35)

FS Electrical flow switch (optional, for unit 20-35)

Units AQH 20-80

Page 15

Product Description

English

Units AQH 90-130

WATER

COLLECTOR

OIL EQUALIZER

Safety & Control Devices:

CPT High-pressure service outlet

DIS Outlet temperature probe

EPT Low-pressure service outlet

EWT Entering water temperature probe

FH1 Pressure switch

FPC Condensing pressure transducer

FPE Evaporation pressure transducer

LWT Leaving water temperature probe

FS Electrical flow switch

Components:

1 Compressors C1/C2

2 Air exchanger

3 Dehydrating filter

4 Liquid lamp

5 Thermostatic expansion valve

6 Plate-type exchanger

7 4-way valve

8 Liquid receiver

9 Check valve

10 Silencer

11 Liquid storage

12 Ball cock

Page 16

Transportortion, Handling and Stockage

3 TRANSPORTATION, HANDLING

AND STORAGE

The AQL/AQH units are supplied fully assembled

and tested (except for the shock absorbers which are

separately supplied). They are ready to be installed

and started on the field.

R407C units are only charged with liquid refrigerant

and with oil in the quantity required for operation.

The low pressure side of the refrigerating

circuit on R407C units shall be charged by

means of the service valve arranged on the

thermal expansion valve before the device

is operated.

3.1 Inspection

The unit shall be immediately inspected upon receipt

to find out any damage since it has been delivered

ex works and transported at the customer’s risk. It is

also necessary to make sure that all the parcels spec-

ified on the delivery note have been delivered.

Any damage you may find out shall be immediately

reported in writing to the carrier. Even if the damage

is only on the surface, please notify our local repre-

sentative too.

The manufacturer disclaims all responsibility for the

shipment even if it has provided for its organisation.

3.2 Handling

The AQL/AQH units are designed to be lifted from

above, by means of cables and eyebolts. A spacer

shall be arranged between the cables in order to

prevent them from damaging the unit (see the figure

aside).

Before handling the devices, make sure the site you

have chosen for the installation can withstand its

weight and support its mechanical impact.

Avoid touching sharp parts (such as the fins of batter-

ies, for example) while handling the unit.

The unit shall never be placed on rollers.

Act as follows to lift and handle the unit:

h

Insert and secure the eyebolts into the frame holes

which have been marked on purpose.

h

Connect the cables to the eyebolts.

h

Insert the spacer between the cables.

h

Provide for hooking at the centre of gravity of the

device.

h

Cables shall have such a length that the angle they

form with the horizon when under tension is not

less than 45°.

Protect cabinet

during lifting

Space requirements

request to handling

Holes Ø 30 mm

Page 17

English

Transportortion, Handling and Stockage

While lifting and handling the unit, pay at-

tention. Otherwise, you might damage the

finned pack of the batteries arranged on

both sides of the unit. The sides of the unit

shall be protected by cardboard or ply-

wood sheets.

Until the unit is ready for operation, do not

remove the plastic envelope and the battery

protections which are intended to prevent

dirt, dust and any foreign matter from pene-

trating into the unit through the inlets of fans

or from damaging the external surfaces.

3.3 Storage

If the unit is to be stored before the installation for

some time, take at least the following precautions to

prevent damage, corrosion and/or deterioration:

h

Make sure all openings, such as for example wa-

ter connections, are well plugged and sealed.

h

Never store the units in a room where temperature

is above 42 °C (R407C units) or where the units

are directly exposed to the sunlight.

h

It is recommended to leave the finned batteries

covered to protect them against any risk of corro-

sion, especially if building works are still in

progress.

h

Store the units in areas where minimum activity is

likely to take place in order to avoid any risk of ac-

cidental damage.

h

Never use steam to clean the unit.

h

Remove all the keys required to have access to the

control panel and give them to the person in

charge of the field.

It is also recommended to provide for visual inspec-

tions at regular intervals.

Page 18

Installation

4 INSTALLATION

4.1 Installation Site

Before installing the unit, make

sure that the building structure

and/or the supporting surface can

withstand the weight of the device.

The weights of the units are de-

tailed by Chapter 9 of this manual.

These units have been designed to be installed on

the floor, in the open air. As a standard, they are

equipped with rubber vibration-damping supports

which shall be arranged in the middle, beneath the

supporting plates.

When the unit is to be installed on the ground, pro-

vide for a concrete bedplate which shall assure a

uniform distribution of the weights.

No special subbase is generally required. Howev-

er, if the unit is to be installed above inhabited

rooms, it is recommended to place it on spring

shock absorbers (40-130 units) which shall reduce

to a minimum the transmission of vibrations to the

structures.

When selecting the installation site, never forget to

consider as follows:

h

The longitudinal axis of the unit shall be parallel

to the direction of the prevailing winds so as to

assure a uniform air distribution on finned ex-

changers.

h

The unit shall never be installed in the proximity

of chimneys for the discharge of boiler flue gas-

es.

h

The unit shall never be installed downwind of

sources of grease contaminated air, such as for

example the outlets of large-kitchen extractors.

Otherwise, grease might build up on the fins of

refrigerant / air exchangers or condensers, act

as a fixing agent for any sort of atmospheric im-

purity and rapidly cause the exchangers to clog.

h

The unit shall never be installed in areas exposed

to heavy snowfalls.

h

The unit shall never be installed in areas exposed

to flooding or beneath drip stones, etc.

h

The unit shall never be installed in narrow inner

court yards or in any other restricted space

where the noise may be reflected by the walls or

where the air expelled by the fans may short-cir-

cuit on the refrigerant/air heat exchangers or

condensers.

h

The installation site shall be characterised by the

presence of the space required for air circulation

and for the performance of maintenance opera-

tions (see chapter 9 for further details).

4.2 Defrost Water Drainage

(only for AQH units)

When AQH units operate in the heat pump mode,

they will discharge water from the bedplate during

defrost cycles.

For this reason it is recommended to install these

units with a minimum ground clearance of 200 mm

to allow the defrost water to drain freely as well as

to prevent it from freezing and forming any ice

build-up.

AQH units shall be installed where defrost water

may cause no damage.

Page 19

Installation

English

4.3 Installation of Spring Shock

Absorbers

h

Prepare the bedplate which shall be smooth and

flat.

h

Lift the device and insert the shock absorbers. For

this purpose follow the instructions here below.

Installation of the vibration-damping sup-

port by means of a jack:

h

Fig. 1) Start assembling the components of the

jack.

h

Fig. 2) Insert the jack into the threaded seat

arranged on the upper plate of the vibration-

damping device. Insert the jack assembled on the

vibration-damping device into the hole arranged

on the bedplate of the machine.

h

Fig. 3) Make sure that the bedplate of the ma-

chine is arranged on the flat washer (pos. E) of

the jack. Use a wrench 13 and act on the high

nut (pos. D) (Fig. 3) to balance any difference in

height.

Use a grower washer (pos. F) and act on the low

nut (pos. C) to lock the position you have

reached.

At the end of the operation make sure the ma-

chine is elastic on the axes and ready for the in-

stallation of any vibration-damping balancing

joint in the water connections.

Fig. 1

Fig. 4

Fig. 3

Fig. 2

Insert

Page 20

Installation

4.4 External Water Circuit

The external water circuit shall guarantee

a constant water flow rate through the cir-

culating refrigerant/water heat exchanger

(evaporator) under steady operating condi-

tions and in case of a load variation.

The circuit shall be composed by the following ele-

ments:

h

A circulation pump which can ensure the neces-

sary flow rate and head.

h

The total content of the primary water circuit shall

never be lower than 2.5 lt/kW in terms of refrig-

erating capacity. If the total water volume in the

primary circuit should be unable to reach such a

value, an additional heat-insulated storage tank

should be installed. This tank is intended to avoid

any repetitive start of the compressor.

h

A membrane expansion tank complete with a

safety valve and a drain which shall be visible.

The expansion tank shall be dimensioned

in such a way that it can absorb a 2% ex-

pansion of the total volume of the water in

the plant (exchanger, pipelines, uses and

storage tank, if available). The expansion

tank shall never be insulated when the cir-

culating fluid is not flowing through it.

A differential pressure switch is mounted on 20-35

units as a standard. It will stop the unit whenever it

senses a load loss through the heat exchanger

which may result in a flow rate problem.

A flow switch is supplied for larger units as a stan-

dard.

In addition:

h

Install on/off valves on the lines at the inlet and

outlet of the manifolds of the exchangers (evapo-

rator).

h

Arrange a by-pass complete with an on/off valve

between the manifolds of the heat exchangers.

h

Arrange air vent valves at the high points of the

water lines.

h

Arrange drain points complete with plugs, clocks,

etc. in the proximity of the low points of the water

lines.

h

Insulate the water lines to prevent the heat from

blowing back into the unit.

Notes:

SF Mesh filter (supplied)

HR Antifreeze resistance of the plate-type exchanger

WPG Attachments for manometers (only on 40/130)

AP Vent valve

FV Water filling valve

PHE Plate-type exchanger

DU Drain cock

FC Flexible joints

FS Flow switch (only on 40/130)

PT Thermometric trap

PE Differential water pressure switch (only on 20/35)

EWC Attachment at the water inlet

LWC Attachment at the water outlet

CV On/Off valves

Version without a pump

PLANT COMPONENTS (NOT SUPPLIED) HYDRO KIT COMPONENTS

Page 21

Installation

English

Before filling the installation, remove any

impurity, such as sand, crushed stones and

welding scales, coating drops and any

other material which might damage the

evaporator.

It is advisable to flush with disposable water by-

passing the exchanger to avoid clogging.

The water used to fill the circuit shall be

treated in such as way that the pH will

have the correct value.

When two or several units are connected in paral-

lel, to balance the load losses of the various cir-

cuits, it is recommended to execute a “reverse re-

turn” connection (see the diagram below).

4.5 Water connections

The attachments at the water inlet and out-

let shall be connected in compliance with

the instructions which can be found on the

labels in the proximity of the attachments.

Connect the water lines of the plants with the at-

tachments of the unit whose diameters and positions

are shown by Chapter 9.

Notes:

SF Mesh filter (outside on 20/35)

ET Expansion tank

SV Safety valve

AP Vent valve

PHE Plate-type exchanger

PU Circulation pump

DU Drain cock

EAV Flow rate calibration valve (only on 40/130)

FS Flow switch (only on 40/130)

PT Thermometric trap

PE Differential water pressure switch (only on 20/35)

HR Antifreeze resistance of the plate-type exchanger

WPG Attachments for manometers (only on 40/130)

EWC Attachment at the water inlet

LWC Attachment at the water outlet

WI Water gauge

CV On/Off valves

FC Flexible joints

FV Water filling valve

Version with a pump

PLANT COMPONENTS (NOT SUPPLIED) HYDRO KIT COMPONENTS

UNIT 1

UNIT 2

Legend

S On/Off valves

VG Balancing valves

Page 22

Installation

4.6 Accumulation Tank Kit

The accumulation tank which has been designed for

mounting on AQL/AQH units is complete with all

the hydraulic and electrical components required

for the correct operation of the system.

These systems are carefully assembled and tested at

works. They are ready for operation after having

correctly realised all electrical and hydraulic con-

nections.

4.6.1 Features

20/35 units have one single tank whereas the units

starting from 40/50 have two tanks complete with

a standard connection. The kit will include an an-

tifreeze resistance, a drain cock, an automatic fill-

ing unit and an automatic air vent.

No pump is arranged on the kit since it is assumed

that the kit is meant for the units with a hydro option

where a pump and an expansion tank are already

available.

A tank arranged for mounting a heating booster re-

sistance kit may be optionally required (5 traps for

the kits from 20 to 50 and 8 traps for the kits for

larger sizes).

The tank is completely insulated with 30 Kg/m

3

closed cell polyethylene in a silver colour and en-

closed by a bearing structure made of passivated

and painted plates. The box is equipped with bulk-

heads which can be easily opened for internal in-

spection.

The kit is installed beneath the chiller. It is an inte-

gral part of the unit without changing the support

area.

Spring shock absorbers are also available for the

units starting from 40.

4.6.2 Supplied Material

The kits will be supplied with pipelines ready for in-

stallation. An antifreeze resistance with wiring, an

automatic water filling valve, a 3 bar safety valve,

a drain cock and a vent valve have already been

assembled.

Everything is placed on wooden pallets with wood-

en joists arranged on the kit for piling up and a film

for protection against atmospheric agents.

4.6.3 Operating Limits

The unit will guarantee the operation at an air tem-

perature of –10°C in a standard configuration with

one single antifreeze resistance.

4.6.4 Shock Absorbers

Shock absorbers are supplied for 20-35 sizes as a

standard. They shall be assembled by the customer

for 40-130 sizes during the installation.

IMPORTANT

Select the shock absorbers for the units with a hy-

dro kit.

4.6.5 Antifreeze Resistance

The antifreeze resistance of the tank (TEH) shall be

wired with the panel as it is shown by the diagram

attached to the unit.

4.6.6 Water Filter

The kit will use the water filter of the unit.

CAUTIONS

The unit + tank system shall be equipped with a fil-

ter for the 20-35 units. Use the filter + union as it is

shown by Figure 3.

Figure 3

Water filter

position

Positioning rubber shock absorbers

Figure 4

Positioning rubber

shock absorbers

Positioning rubber shock absorbers

Machines from 40 to 130

Page 23

Installation

English

4.6.7 Installation Procedure

The accumulation kits shall be arranged beneath

the unit. They will not change its overall dimensions

(Figure 3 and 4).

Arrange the rubber shock absorbers beneath the kit

before providing for its connection.

The installation of the spring shock ab-

sorbers will replace the installation of the

rubber shock absorbers supplied with the

accumulation kit.

Arrange the rubber shock absorbers between the

unit and the kit for the 40-130 units (Figure 4).

Tighten the screws into the holes arranged on the 4

corners in order to fasten the unit to the accumula-

tion kit.

Provide for the hydraulic and electrical connections.

In doing so, observe the diameters shown by the

quoted drawings.

The wiring for the standard antifreeze resistance is

arranged as it is shown by Figure 1 and 2 for the

different types of accumulation. The resistance is

connected with the main terminal box for the 20-25-

30-35 models and with the pull box arranged in the

fans department for larger sizes.

See the wiring diagram attached to the unit for the

correct execution of the electrical connections.

Install the water filter as it is shown by Figure 3 for

the machines of the 20-25-30-35 size.

Figure 1

Figure 2

Antifreeze

Resistance Wiring

Antifreeze

Resistance Wiring

Page 24

Installation

Storage Kit (112 l) for AQL/AQH 20-35 - Dimensional Data

Storage Kit (224/112 l) for AQL 40-50 / AQH 40 - Dimensional Data

SIDE VIEW

FRONT VIEW

TOP VIEW

NOTES:

A - WATER INLET ON THE PLANT SIDE Ø 1 1/2” GAS M

B - WATER OUTLET ON THE CHILLER SIDE Ø 1 1/2” GAS M

C - WATER FILLING Ø 1/2” GAS M

SIDE VIEW

FRONT VIEW

TOP VIEW

NOTES:

A - WATER INLET ON THE PLANT SIDE Ø 2” GAS M

B - WATER OUTLET ON THE CHILLER SIDE Ø 2” GAS M

C - WATER FILLING Ø 1/2” GAS M

Page 25

Installation

English

SIDE VIEW

FRONT VIEW

TOP VIEW

NOTES:

A - WATER INLET ON THE PLANT SIDE Ø 2” GAS M

B - WATER OUTLET ON THE CHILLER SIDE Ø 2” GAS M

C - WATER FILLING Ø 1/2” GAS M

Storage Kit (294/147 l) for AQL 60-80 / AQH 50-80 - Dimensional Data

FRONT VIEW

TOP VIEW

NOTES:

A - WATER INLET ON THE PLANT SIDE Ø 2” GAS M

B - WATER OUTLET ON THE CHILLER SIDE Ø 2” GAS M

C - WATER FILLING Ø 1/2” GAS M

Storage kit (294-147 l) for AQL/AQH 90-100 / AQH 90 - Dimensional Data

SIDE VIEW

Page 26

Installation

SIDE VIEW

FRONT VIEW

TOP VIEW

Storage Kit (294/147 l) for AQL/AQH 110-130 / AQH 100-130 - Dimensional Data

NOTES:

A - WATER INLET ON THE PLANT SIDE Ø 2” GAS M

B - WATER OUTLET ON THE CHILLER SIDE Ø 2” GAS M

C - WATER FILLING Ø 1/2” GAS M

Page 27

Installation

English

Page 27

4.7 Electrical Supply Features

Make sure the unit is not alive be-

fore acting on the electrical instal-

lation.

The unit shall be grounded.

The installer shall make sure that all the ex-

ternal connections of the unit have been re-

alised in compliance with the safety rules

in force.

The manufacturer is not responsible for

any damage and/or accident which may

result from the non observance of these

precautions.

The unit complies with the EN 60204-1 standard.

The following connections are required:

h

A pr=N three-phase line with earthing for the

power supply or without N for the units not re-

quiring it.

The electrical installation for distribution shall be

able to supply the power absorbed from the device

(see Chapter 9).

Disconnectors and magnetothermal switches shall

be dimensioned in such a way that they can handle

the pick-up current of the unit (see Chapter 9).

Power supply lines and insulation devices shall be

designed in such a way that every line is complete-

ly independent.

It is recommended to install the differential switches

which shall prevent any damage due to any phase

loss.

Fans and compressors are supplied by contactors

controlled by the control panel.

Each motor is complete with an internal safety ther-

mal switch as well as with external fuses or magne-

tothermal switches.

Power supply cables shall be run through the en-

trance passage which can be found on the front

side of the unit and then routed into the electrical

panel through the holes at its bottom.

4.8 Electrical Connections

The installation of the unit on the field

shall be carried out in compliance with the

Machinery Safety Directive (EEC 98/37),

the Low Voltage Directive (EEC 73/23), the

Electromagnetic Compatibility Directive

(EEC 89/336) as well as the usual proce-

dures and standards in force. The unit

shall never be operated if its installation is

not carried out according to the instruc-

tions above. The power supply lines shall

be composed by insulated copper wires

dimensioned for the maximum current

which may be absorbed.

Dimensioning shall be performed by con-

sidering the file length, the type of cable in

use, the type of installation as well as the

maximum operating room temperature.

Terminal connections shall be made according to

the connection diagram attached to this manual

and the wiring diagram supplied with the unit.

Before connecting the power supply lines,

make sure that the voltage value lies within

the limits shown by the Electrical Data in

Chapter 9.

Make sure that the unbalance between the phases

will not exceed 2% for three-phase systems. Check

by measuring the differences between the voltage

values of every single phase couple and their aver-

age value during the operation. The maximum per-

centage value of these differences (unbalance) shall

never exceed 2% of the average voltage.

If the unbalance should be unacceptable, contact

the Power Supply Company and require it to cor-

rect the fault.

If the unit is supplied by a line whose un-

balance is higher than the admitted value,

the warranty will automatically become

null and void.

Page 28

Installation

Electrical Connections of the AQL/AQH 20-35 units with Neutral

230Vac – AVAILABLE FOR ACCESSORIES

NOT PROTECTED

EXTERNAL FLOW SWITCH

EXTERNAL INTERLOCK

EXTERNAL PUMP APPROVAL

ALARMED UNIT + NO. SPTS

MAX 2,5 A @ 250 Vac

START/STOP REMOTE SWITCH

HEATING / COOLING SELECTION

NIGHT MODE OR DOUBLE SET POINT

SELECTION

FORCED LOAD SHEDDING

DISCONNECTOR

COMMON

HOT / COLD

TERMINAL BOARD ON THE MACHINE

USER CONNECTIONS

POWER LINE

400/ 3+N/50 – PE

SECTION

ELECTRONIC BOARD

PUMP CONTROL RELAY

TERMINAL 108 HYDRO KIT

TERMINAL 8 HYDRO KIT

TERMINAL 14 HYDRO KIT

TERMINAL 8 HYDRO KIT

TERMINALS ON THE MACHINE

TERMINALS FOR EXTERNAL

CONNECTIONS

NOTE: Always refer to the machine wiring diagram.

VOLTAGE FREE CONTACTS

ANTIFREEZE RESISTANCE CONTROL RELAY

Page 29

Installation

English

Page 29

Electrical Connections of the AQL/AQH 40-80 units with Neutral

ELECTRONIC BOARD

TERMINAL 108 HYDRO KIT

TERMINAL 8 HYDRO KIT

TERMINAL 14 HYDRO KIT

TERMINAL 8 HYDRO KIT

ANTIFREEZE RESISTANCE CONTROL RELAY

230Vac – AVAILABLE FOR ACCESSORIES

NOT PROTECTED

EXTERNAL FLOW SWITCH

EXTERNAL INTERLOCK

EXTERNAL PUMP APPROVAL

ALARMED UNIT + NO. SPTS

MAX 2,5 A @ 250 Vac

START/STOP REMOTE SWITCH

HEATING / COOLING SELECTION

NIGHT MODE OR DOUBLE SET POINT

SELECTION

FORCED LOAD SHEDDING

DISCONNECTOR

COMMON

HOT / COLD

TERMINAL BOARD ON THE MACHINE USER CONNECTIONS

POWER LINE

400/ 3+N/50 – PE

SECTION

PUMP CONTROL RELAY

TERMINALS ON THE MACHINE

TERMINALS FOR EXTERNAL

CONNECTIONS

NOTE: Always refer to the machine wiring diagram.

VOLTAGE FREE CONTACTS

Page 30

Installation

Electrical Connections of the AQL/AQH 40 - 80 units without Neutral

230Vac – AVAILABLE FOR ACCESSORIES

NOT PROTECTED

EXTERNAL FLOW SWITCH

EXTERNAL INTERLOCK

EXTERNAL PUMP APPROVAL

ALARMED UNIT + NO. SPTS

MAX 2,5 A @ 250 Vac

START/STOP REMOTE SWITCH

HEATING / COOLING SELECTION

NIGHT MODE OR DOUBLE SET POINT

SELECTION

FORCED LOAD SHEDDING

DISCONNECTOR

COMMON

HOT / COLD

TERMINAL BOARD ON THE MACHINE

USER CONNECTIONS

POWER LINE

400/ 3/50 – PE

SECTION

TERMINALS ON THE MACHINE

TERMINALS FOR EXTERNAL

CONNECTIONS

NOTE: Always refer to the machine wiring diagram.

VOLTAGE FREE CONTACTS

ELECTRONIC BOARD

PUMP CONTROL RELAY

TERMINAL 108 HYDRO KIT

TERMINAL 8 HYDRO KIT

TERMINAL 14 HYDRO KIT

TERMINAL 8 HYDRO KIT

ANTIFREEZE RESISTANCE CONTROL RELAY

Page 31

Installation

English

MORSETTIERA BORDO MACCHINA COLLEGAMENTI UTENTE

SEZIONATORE

LINEA POTENZA

400/3+N/50 + PE

ON/OFF

COMUNE

CALDO/FREDDO

MORSETTI A BORDO MACCHINA

CONTATTI PRIVI DI TENSIONE

NOTA: riferirsi sempre allo schema elettrico a bordo macchina

230Vac DISPONIB. PER ACCESSORI

MAX 40VA

INTERBLOCCO ESTERNO

CONSENSO POMPA ESTERNA

UNITA’ IN ALLARME - N.O. SPST

MAX 2.5A @ 250Vac

INTERRUTTORE REMOTO

DI MARCIA ARRESTO

SELEZIONE RISCALD/RAFFREDD.

SELEZIONE MODALITA’ NOTTE

O DOPPIO SETOPOINT

PARZIALIZZAZIONE FORZATA

DELLA CAPACITA’ FRIGORIFERA

MORS. 103 HYDROKIT

MORS. 8 HYDROKIT

MORS. 14 HYDROKIT

MORS. 8 HYDROKIT

RELE’ COMANDO POMPA

SCHEDA ELETTRONICA

RELE’ COMANDO RESISTENZA ANTIGELO

TERMINAL BOARD ON THE MACHINE USER CONNECTIONS

SECTION

POWER LINE

400/ 3/50 – PE

DISCONNECTOR

COMMON

HOT / COLD

TERMINALS ON THE MACHINE

TERMINALS FOR EXTERNAL

CONNECTIONS

VOLTAGE FREE CONTACTS

NOTE: Always refer to the machine wiring diagram.

230Vac – AVAILABLE FOR ACCESSORIES

NOT PROTECTED

EXTERNAL FLOW SWITCH

EXTERNAL INTERLOCK

EXTERNAL PUMP APPROVAL

ALARMED UNIT + NO. SPTS

MAX 2,5 A @ 250 Vac

START/STOP REMOTE SWITCH

HEATING / COOLING SELECTION

NIGHT MODE OR DOUBLE SET

POINT SELECTION

FORCED LOAD SHEDDING

TERMINAL 103 HYDRO KIT

TERMINAL 8 HYDRO KIT

TERMINAL 14 HYDRO KIT

TERMINAL 8 HYDRO KIT

PUMP CONTROL RELAY

ELECTRONIC BOARD

ANTIFREEZE RESISTANCE CONTROL RELAY

Electrical Connections of the AQL/AQH 90 - 130 units without Neutral

Page 32

Commissioning

5 COMMISSIONING

The unit may only be started by the person-

nel trained by an authorised Itelco-Clima

Service Centre. Otherwise, the warranty

will be automatically made null and void.

The operations performed by the technical

service personnel are limited to the start-up

of the unit. They do not include any other

work on the installation, such as for exam-

ple the execution of electrical, hydraulic

connections, etc. All the other operations

preparatory to the start-up, including oil

pre-heating for at least 12 hours, shall be

carried out by the Installer.

5.1 Preliminary Checks

The following operations shall be performed before

the arrival of the Itelco-Clima personnel on site in

order to start up the unit.

h

Check the sections of supply cables, the ground

connection, the clamps of terminals and the good

operation of contactors when the main discon-

nector is open.

h

Make sure the R.S.T. phase sequence is correct.

h

Make sure the unbalance between the supply line

phases is within the limits as per Chapter 4.

h

Connect (without any supply) the flow switch con-

tacts, the pump thermal overload cut-out or any

other device to terminals 1-2 and 3-4.

h

Make sure the components of the water circuit

connected to the circulation refrigerant / fluid ex-

changer (pumps, sensors, uses, expansion tank

and storage tank, if any) are correctly installed in

compliance with the instructions of the manufac-

turers.

h

Make sure that the water circuits have been filled

and the circulation of the various fluids occurs

correctly, without any sign of leakage or air bub-

bles. If ethylene glycol is used as an antifreeze,

make sure its mixture percentage is correct.

h

Make sure that the direction of rotation of the

pumps is correct and the fluids have circulated

for at least 12 hours for each pump. Clean the

baskets of the filters on the aspirating side of the

pumps.

h

Calibrate the installation so that the fluid will

have the specified flow rate.

h

Make sure the quality of the circulating fluid com-

plies with the specifications.

h

Make sure oil electrical heaters have been ener-

gised for at least 12 hours.

5.2 Starting

The starting sequence shall be performed as fol-

lows:

h

Close the main disconnector (at least 12 hours

before).

h

Make sure that the oil inside the compressors is

hot enough (the external temperature of the oil

pan shall be at least 40 °C) and the auxiliary cir-

cuit of controls is energised.

h

Make sure that the whole external equipment is

perfectly working and the control devices of the

installation are properly calibrated.

h

Start the pumps of the circulating fluids and make

sure they can deliver the flow rate required.

h

Set the fluid temperature you wish on the control

panel (refer to Chapter 6).

h

Start the unit you wish (refer to Chapter 6).

h

Check the direction of rotation of scroll compres-

sors.

h

After about 15 minutes make sure no gas bubble

is visible through the sight glass of the liquid line.

If air bubbles are visible through the sight

glass, it means that the unit has lost part of

its charge through one or several leakage

points. The leaks shall be removed. Refer

to Chapter 7.

h

Repeat the starting procedure after having re-

moved the leaks.

h

Make sure the oil level is correct.

MAX

MIN

Page 33

English

Commissioning

5.3 Performance Check

Check as follows:

h

The inlet temperature of the fluid circulating in the

manifold of the exchangers.

h

The outlet temperature of the fluid circulating in

the manifold of the exchangers.

h

The flow rate of the fluid through the exchangers.

h

The current absorbed by compressors and fans at

the start-up and under steady operating condi-

tions.

Check the saturated evaporation and condensation

temperatures during the unit operation by connect-

ing the manometers with the two Schraeder valves

which can be found on the low and high pressure

side of refrigerating circuits.

5.4 Delivery to the User

h

Inform the user about the instructions for use

which can be found in Chapter 6.

High

pressure side

Low pressure

side

15-18°C above the air inlet temperature in

the battery.

5-7°C below the outlet temperature of the

water circulating from the evaporator.

Page 34

AQL/AQH Control

^ SWITCH

makes it possible to vertically scroll through the

MENUS and SUB-MENUS and to increase the nu-

merical value of the parameters.

TEST SWITCH

Starts an automatic testing procedure for all the main

functions of the unit. See TESTING PROCEDURE.

6 AQL/AQH CONTROL

6.1 Electronic Card Control

h

Keyboard

Display

SM1 Switch

TEST

Machine ON

SM1 SWITCH:

– position 0: machine OFF. The resistors may be en-

abled. Test available.

– position 1: machine ON. Test available.

> SWITCH

makes it possible to horizontally scroll through the

MENUS and to display the parameter values

Page 35

English

AQL/AQH Control ERRATA CORRIGE

DIP OFF ON STANDARD

1 Pump ON only if the unit is ON Pump always ON OFF

2 Step ventilation Continuous ventilation OFF

3 Pump Off in antifreeze protection Pump On in antifreeze protection ON

4 Discharge of comp. 1 Discharge of comp. 2 OFF

5 Normal Slave OFF

6 Room temperature compensation No compensation ON

7 Enable input 5 pump’ thermal switch Disable input 5 pack unit = OFF

non pack = ON

8 Forced defrosting OFF Forced defrosting ON OFF

9 Serial address OFF

10 Serial address OFF

11 Serial address OFF

12 Serial address OFF

Display keys

Display menus

Display keys

Display menus

cool

6.2 Dip Switches

The control is provided with 2 DIP switch blocks:

DSW1 (12 dips) and DSW2 (8 dips).

FUNCTION OF DSW1 DIPS

h

Display keys

All th information is displayed on 4 displays (7-seg-

ments).

Use the > and ^ keys to enter the display menus as

follows:

Page 36

AQL/AQH Control

Page 37

English

AQL/AQH Control

6.3 ALAr and LOg Menus

The activated alarms of the unit are displayed in the

ALAr menu. More alarms can be activated at the

same time. The alarms are recorded in a permanent

LOG memory.

Code Alarm description Auto Manual Notes

ADC Microprocessor error

CPF failure of HP transducer, off scale

EPF failure of LP transducer, off scale

REF refrigerant leak - low pressure

CPnc failure of HP transducer, unchanged pressure

EPnc failure of LP transducer, unchanged pressure

CFC1 failure of compressor 1 wrong rotation

CFC2 failure of compressor 2 wrong rotation

EWTH failure of return water probe short-circuit

EWTL failure of return water probe not connected

LWTC no variation in the leaving water temperature

LWTH failure of leaving water probe short-circuit

LWTL failure of leaving water probe not connected

LWLH failure of compressor discharge temperature probe short-circuit

DISL failure of compressor discharge temperature probe not connected

OATH failure of air temperature probe short-circuit

OATL failure of air temperature probe not connected

OC1L failure of temperature probe - coil 1 not connected

OC2L failure of temperature probe - coil 2 not connected

HPP first high pressure protection stop1 compressor

HP high pressure protection from transducer

auto energized 3 times

HPC high pressure protection - locked circuit

LP low pressure protection

DIS excessive discharge temperature of compressors

LO insufficient leaving water temperature

HI excessive entering water temperature

FS electrical flow switch or water differential pressure switch

CF1 thermal protection, compressor 1

CF2 thermal protection, compressor 2

OF1 thermal protection, fans

PF thermal protection, pump

LOu low water volume

EEP microprocessor error

JUMP wrong DIP configuration DIP check

ConF wrong configuration

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

The last 10 recorded alarms are displayed in the

LOg menu. The following table shows the alarm

codes and description:

6.4 SEnS Menu – Sensors reading

Displayed Code Meaning

EWT entering water temp

LWT leaving water temp

CP discharge pressure

EP intake pressure

CPS sat. temperature (discharge)

EPS sat. temperature (intake)

Dis compressor’s discharge temp

OAT room air temp

OCT 1 probe temperature in coil 1

OCT 2 probe temperature in coil 2

Page 38

Maintenance

Check the temperature of the fluid

leaving the exchanger

Check any exchanger load loss

Check the electrical absorption

Check the suction temperature and

pressure

Check the delivery temperature and

pressure

Check the compressor oil level

Make sure there is no gas bubble in

the liquid line

Make sure the finned pack of the

external battery is clean

Check the operation of the oil

heater

Check the operation of the Remote

Control Unit

Check the operation of the high

pressure switch

Check the insulation of the

circulating refrigerant / fluid

exchanger

Make sure the screws of terminals

are firmly tight

Clean the external surfaces of the

unit with soapy water

Check the operation of the

differential pressure switch

Check the density of the antifreeze

mixture (glycol water) if this mixture

is used

Drain and clean the circulating

refrigerant / fluid exchangers

7 MAINTENANCE

While discharging the refrigerating

circuits, never release the refriger-

ant into the atmosphere. Use prop-

er recovery equipment for the dis-

charge. If the recovered refrigerant

can not be reused, it shall be re-

turned to the producer.

Never dispose of the compressor oil

in the atmosphere since it contains

dissolved refrigerant. If used, the oil

shall be returned to the producer.

The Safety Section of this manual shall be

carefully read before performing any

maintenance operation on the unit.

Unless otherwise specified, the maintenance opera-

tions here below can be performed by any mainte-

nance technician who has been specifically trained.

7.1 General Information

Itelco-Clima AQL/AQH units have been designed

for constant operation, provided that they are regu-

larly serviced and operated within the limits speci-

fied by this manual. Every unit shall be serviced ac-

cording to a User / Customer schedule and regularly

inspected by the personnel from an authorised Itelco-

Clima Service Centre.

It is the User’s responsibility to fulfil these mainte-

nance requirements and/or make an agreement

with an Itelco-Clima Service Centre so as to protect

the operation of the device.

If any damage or failure should occur as a result of

improper maintenance during the warranty period,

Itelco-Clima will not be liable for any cost required to

restore the original state of the device.

This section is only applicable for basic AQL/AQH

units. According to the circumstances, it might be

supplemented with additional instructions as a result

of any change which may be made to the unit or to

the use of the ancillary equipment.

7.2 Daily Maintenance

Maintenance checks shall be performed by a com-

petent person according to the schedule here

below.

Operations

Daily

Weekly

Monthly

Season start

Season end

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

••

•

However, it shall be noted that AQL/AQH units can

not be directly repaired by the User who shall refrain

from attempting to repair any failure which may be

discovered during daily maintenance. In case of

doubt, contact the Itelco-Clima Service Centre.

Scheduled Maintenance

Page 39

English

Maintenance

7.3 Refrigerant Charge

AQL/AQH units operating with R407C

shall be exclusively charged with refriger-

ant in the liquid state to prevent the refriger-

ant composition from altering. A service

valve is arranged for charging the unit at

low pressure.

If the charge is not enough, the unit will reduce its

performance. In extreme cases, the low pressure

switch might trip and cause the unit to stop.

If the charge is too large, the condensation pressure

might increase to such an extent that it might cause

the high pressure switch to trip and the unit to stop.

The compressors of the unit shall never be

used as vacuum pumps to discharge the

corresponding circuits.

The refrigerating circuit shall be recharged whenev-

er it has been discharged for maintenance purposes

(elimination of leaks, compressor repair, etc.).

Charge quantities are specified by Chapter 9.

Before being charged, every circuit shall be dried

and vacuum-purged so that the absolute pressure

may not exceed 50 Pa inside it.

7.4 Compressors

Compressors are supplied with the oil quantity re-

quired for operation. This charge should last as long

as the compressor under normal operating condi-

tions. The lubricant shall not be topped up as long as

the refrigerating circuit is operating correctly and un-

til no repair has been carried out.

If a compressor is faulty and it is to be replaced, re-

placement may be only carried out by the personnel

of an Authorised Service Centre.

7.5 Refrigerant/Air Exchangers

They are made up of copper tubes and aluminium

fins. If the refrigerant should leak as a result of an ac-

cidental damage, repair operations may be only car-

ried out by the personnel of an Authorised Service

Centre.

To make service and maintenance operations easier,

the external surfaces of these exchangers shall al-

ways be kept free of any impurity, such as leaves, fi-

bres, insects, etc. If heat exchangers are dirty, the

power absorbed may increase. This may also cause

the unit to reach such a pressure threshold which

might trigger an alarm and cause the unit to stop.

Avoid damaging the aluminium finned

pack during cleaning.

The internal side of the finned pack of these ex-

changers can be cleaned by compressed air orient-

ed parallel to the finned pack and in a direction op-

posite to that of the normal air circulation. The exter-

nal side can be cleaned by a vacuum cleaner. The

finned pack of these exchangers can be also

cleaned by spraying a water and soap solution.

7.6 Fans of the Refrigerant/Air

Exchangers

Each fan has got an impeller with wing contoured

blades and a cylindrical conveyor. The bearings of

the motors are life lubricated for life.

7.7 Dryer Filter

Refrigerating circuits are complete with dryer filters.

These filters can not be inspected and they are com-

plete with a mechanical filter. When the dryer filter is

clogged, this is shown by the presence of gas bub-

bles in the sight glass and by a temperature differ-

ence between the side upstream and downstream

the filter.

If the presence of gas bubbles should persist after the

filter cartridge has been replaced, it means that the

unit has lost part of the refrigerant charge through

one or more leaks which shall be identified and re-

paired.

Page 40

Maintenance

7.8 Sight Glass

The sight glass is used to observe the liquid refriger-

ant flow and to find out if there is some humidity in-

side it. If there are some gas bubbles in the liquid

flow, it means that the dryer filter is clogged or that

the refrigerant charge has partially leaked out.

A coloured indicator is arranged inside the sight

glass. If you compare its colour with the chromatic

scale arranged on the external ring of the sight

glass, you may find out if there is some humidity in

the refrigerant. If the humidity content should be too

high:

h

Discharge the circuit and collect the refrigerant.

The circuit shall be then vacuum-purged and

recharged.

7.9 Thermal Expansion Valves

The refrigerating circuits of the AQL/AQH units are

equipped with a thermal expansion valve complete

with an external equaliser. This valve is calibrated at

works to ensure 5 K overheating.

Act as follows to control overheating:

Read the suction pressure by using a manometer

connected with the filling valve on the suction side.

Use the thermometric scale of the manometer to iden-

tify the Tsa saturated temperature corresponding to

the pressure you have measured.

Measure the Tse effective suction temperature by us-

ing a contact thermometer arranged on the attach-

ment at the outlet of the evaporator gas.

Overheating is calculated as follows:

S = Tse – Tsa

Or use the Menu function

Overheating can be changed by acting on the cali-

brating screw of the thermal expansion valve. Turn

this screw clockwise to increase overheating. Turn it

counterclockwise to decrease overheating.

The valve shall be calibrated again by turning the

calibrating screw by one revolution at a time and

then by operating the unit for 5 minutes. After this pe-

riod of time has elapsed, check overheating and cor-

rect it again, if required.

The thermal expansion valves of the AQH

models shall be calibrated with the utmost

care since every circuit of these units has

got one single thermal expansion valve

which is used both in cooling and in heat-

ing mode.

If the thermal expansion valve can not react to the

overheating calibration, it means that it is not operat-

ing correctly and that it shall be replaced. The ther-

mal expansion valve may be only replaced by an

Authorised Service Centre.

7.10 Refrigerant / Circulating Fluid

Exchanger

The cleanness of these exchangers on the water side

shall be checked at regular intervals. This can be ac-

complished by checking the load loss on the water

side (see Chapter 9) or by checking the difference

between the incoming and outgoing fluid tempera-

ture and by comparing these values with the evapo-

ration temperature.

The difference between the outgoing fluid tempera-

ture and the evaporation temperature shall lie be-

tween 5 and 7 K to enable the heat exchange to oc-

cur optimally. A greater difference means that the ex-

changer is not working optimally since it is dirty.

In these cases, this exchanger shall be chemically

cleaned by the personnel authorised by the manufac-

turer.

Contact an Authorised Service Centre for any other

type of operation (extraordinary maintenance, re-

placement of the whole exchanger, etc.).

Contact an Authorised Service Centre for any other

type of service (extraordinary maintenance, replace-

ment of heat exchangers, etc.).

Page 41

English

Trouble Shooting

8 TROUBLE SHOOTING

The following table will give a detailed list of unit faults and remedies. Contact an Authorised Itelco-Clima

Service Centre for any other problem which can not be clearly ascribed to one of the cases listed in the table

and/or for any other need for technical assistance.

Fault

The unit operates continuous-

ly, but without cooling.

Hoar-frost is building on the

suction line.

The noise level is too high.

The compressor oil level has

decreased.