QUARTZ

™

ELECTRIC

INSTALLATION AND USER GUIDE

2

CONTENTS

Important Information 3

Safety Information 3

Introduction 4

Electrical Rating 5

Flushing 6

Pipeworks Connections 6

Isolating Valves 7

Siting 7

Pressures 7

Pressure Relief Device (PRD) 8

Inspection and Maintenance 9

After Installation 9

Declaration of Conformity 9

Positioning Guide 10

Components 12

Installation 13

Pipework 13

Electrical Installation 15

Mains Voltage Connection 16

Electrical rating 18

Wiring Connection 18

Earth Bonding 20

Front Cover Preparation 20

Commissioning and Front Cover Installation 21

Shower Kit 23

Pressure and Flow Readings 26

User Instructions 27

Operating the Shower 27

Safety, Maintenance and Care 27

Shower Head Operation 28

Cleaning and Maintenance 29

Cleaning the Filter 29

Pressure Test Adaptor - fitting and user instructions 30

Troubleshooting 31

3

IMPORTANT INFORMATION

Safety information

This appliance can be used by children aged from 3 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

The spray head must be descaled regularly.

This appliance is intended to be permanently connected to the

water mains and not connected by a hose set.

A suitable double pole isolation switch for supply

disconnections must be incorporated in the fixed wiring

circuit, in accordance with current wiring rules. See Electrical

Installation section for further details. This product must be

installed by a competent person in accordance with all relevant

current Water Supply Regulations.

ALL SHOWERS REQUIRING AN ELECTRICAL CONNECTION

MUST BE INSTALLED BY A QUALIFIED PERSON FOLLOWING

THE LATEST REVISION OF BS 7671 (WIRING REGULATIONS)

AND CERTIFIED TO CURRENT BUILDING REGULATIONS.

WITH REFERENCE TO BUILDING REGULATION PART P,

ANY NEW INSTALLATION OR REPLACEMENT PRODUCT

INSTALLATION WHICH IS NOT IDENTICAL TO THE

PRODUCT BEING REPLACED, THE CABLE SIZES, CIRCUIT

4

PROTECTIVE DEVICES, EARTH BONDING AND ALL OTHER

REQUIREMENTS OF THE BUILDING REGULATION MUST BE

ASSESSED BY A (REGISTERED) QUALIFIED ELECTRICIAN

AND INSTALLED IN CONSIDERATION TO THE SITE

CONDITIONS

(See table below).

Introduction

Quartz™ Electric is a surface mounted instantaneous electric

shower unit which is available in a choice of performance

ratings – 8.5kW, 9.5kW and 10.5kW available in Chrome, White/

chrome and Graphite.

Quartz™ Electric features an illuminated start/stop button.

Quartz™ Electric’s patented Over Temperature Protection

(OTP) device ensures safer comfortable showering whilst the

shower provides endless economical showering as it imposes no

demand on stored hot water.

Aqualisa products are supplied complete with a 1 year guarantee

that can be upgraded by registering the product with Aqualisa.

See www.aqualisa.co.uk/guarantee for details.

General notes

If you have any questions at any stage during the fitting of this

product, please contact the Aqualisa customer helpline on

01959 560010.

5

Type

of

cable

run

Shower Rating @ 240V 8.5KW 9.5KW 10.5KW

Nominal current @ 240V 35.4A 39.6A 43.8A

MCB rating 40A 40A 45/50A

Cartridge fuse 40/45A 40/45A 45A

Min cable

size mm

²

Max cable

run in m

Min cable

size mm

²

Max cable

run in m

Min cable

size mm

²

Max cable

run in m

Installed in

insulated wall

10 61 10 55 10 50

Conduit or trunking 6 37 10 55 10 50

Clipped direct or

buried in

uninsulated wall

6 37 6 33 10 50

Notes:

1. Cable selection is dependant on de-rating factors detailed in

the electrical rating section.

2. In certain installations the combination of low voltage and

extended cable lengths may result in loss of power and a

consequential reduction in flow rates.

6

3. Cable sizes detailed are the minimum acceptable sizes. Sizes

greater than these shown above may be used and should be

used if cable runs are greater than indicated (above cable runs

are based on a maximum 9.6V drop).

4. Rewirable fuses are not recommended and not covered by

this table.

5. Installation should be carried out by a qualified person.

Please refer to BS7671 (Wiring Regulations) if in doubt.

6. A 16mm² cable may be required for longer cable runs.

Cables which are chased into the wall must be protected by

the use of conduit or sheathing. Surface mounted cables must

also be protected by a suitable approved conduit.

Before removing the shower heater cover, ensure the heater is

isolated from the electric mains.

Quartz™ Electric is suitable for household use only.

Flushing

Some modern fluxes can be extremely corrosive and, if left in

contact, will attack the working parts of this unit. All soldering

must be completed and the pipework thoroughly flushed out

in accordance with current Water Supply Regulations prior to

connection of the product.

Connections

Quartz™ Electric is suitable for use with 15mm British Standard

pipe and should be connected using a 15mm compression

fitting (not supplied). Quartz™ Electric is suitable for bottom,

top or rear entry pipework and cable. Supply lines should be

flushed clear of any debris prior to installation of the unit.

7

Isolating valves

A suitable full bore isolation valve must be fitted to the

incoming supply in accordance with the current Water Supply

Regulations and our terms of warranty.

Siting

Refer to positioning guideline. The Quartz™ Electric unit must

be mounted on a flat, vertical finished wall with the hose outlet

pointing downwards. Any distortion of the back plate may result

in the unit not working. Spacers are provided and are attached

to the service tunnel. If required, these can be used to enable the

unit to be fitted to an uneven wall surface, if required.

DO NOT tile up to the unit or apply silicone. The shower is spaced o the

wall by integral pillars to allow air circulation around the unit.

•

!

The casing must not be sited where it is subjected to continuous

spray from the shower head. The Quartz™ Electric should not

be sited in any situation where it is likely to freeze.

WARNING DO NOT SWITCH THE SHOWER ON IF THERE IS A

POSSIBILITY THAT THE SHOWER COULD BE FROZEN. If you

have switched the shower on, SWITCH OFF IMMEDIATELY.

Please refer to the trouble shooting guide.

Water pressure

Check that the dynamic (running) water pressure to the

Quartz™ Electric is adequate. Using the pressure test

adaptor provided, follow the pressure test adaptor fitting

and user instructions to ensure the water pressure to the

shower is within the minimum and maximum requirements.

8

The pressure test adaptor must be left with the customer.

Max: 1.0MPa (10 bar)

Min: 0.09MPa (0.9 bar) at a flow rate of 8 litres per minute

The Quartz™ Electric shower is designed to control static

pressure up to 1.0MPa (10 bar). Where pressures are likely to

exceed 1.0MPa (10 bar), a pressure reducing valve must be

fitted into the incoming mains supply. A setting of 0.3MPa

(3 bar) is recommended. It should be noted that daytime

pressures approaching 8 bar can rise above the stated

maximum overnight.

The use of other services connected to the water supply to

the shower unit may cause the water pressure to drop below

the minimum required. This should therefore be taken into

consideration.

The water inlet of this appliance shall not be connected to

inlet water obtained from any other water heating system.

Pressure relief device (PRD)

To meet European standards, the shower unit features an

integral pressure relief device ( PRD).

DO NOT operate the shower with a damaged or kinked

hose or blocked shower head, as this can cause the PRD

to operate. Failure to follow this instruction will invalidate

the guarantee.

The shower will only function correctly with the hose

and handset provided (see shower head installation

instructions page 23). Failure to do so may result in the

operation of the PRD and will invalidate the guarantee.

9

Please fully commission the shower prior to use following

the shower commissioning procedure detailed on page 21.

Failure to do so could cause the PRD to operate and will

invalidate the guarantee.

The shower unit must be sited over a bath or shower tray

as in the event of the PRD operating, water will drain

from the bottom of the shower unit.

Inspection & maintenance

In the interests of safety, we recommend the Quartz™

Electric and its electrical installation are checked by a

qualified electrician at least every 2 years.

Cleaning the filter should only be completed by a qualified

person. Please refer to the instructions of how to clean the

filter, page 29.

After installation

Familiarise the end user with the operation of this

product and hand them this guide. Complete and post the

guarantee card or register online at www.aqualisa.co.uk.

Declaration of Conformity

Aqualisa Products Limited declares that the Quartz™ Electric

shower, complies with the essential requirements and other

relevant provisions of the Low Voltage Directive (2014/35/

EU) and the EMC Directive (2014/30/EU). The PRD provides a

degree of shower unit protection should an excessive build up

of pressure occur within the shower.

10

POSITIONING GUIDE

This product must be installed by a competent person in accordance

with all current Water Supply Regulations.

•

!

< 165mm

> 25mm

Approx.

1,400mm

<320mm

A

B

1

2

3

4a

4b

7

6

5

11

Appendix

1. Distance between top of the chrome rail and top of

the shower engine is a maximum of 320mm.

2. Hose retaining ring.

3. 25mm minimum.

4a. Bath spillover level.

4b. Shower tray spillover level.

5. Distance between height of user and top of chrome

rail is maximum 165mm (Average person height

1,750mm).

6. If A & B measurement guidelines are followed,

the pipework entry point for the shower will be

approximately 1,400mm from standing level in the

shower tray or bath.

7. The depth/height of the shower tray or bath must be

taken into consideration when completing first fix.

To comply with water regulations, building

regulations or any specific local water company

regulations and in accordance with BS EN 806

a double check valve should be fitted where it

is possible that the shower head may come into

contact with user water, for example in the bath

or a shower tray.

•

!

12

COMPONENTS

In addition to this installation guide it is essential that the written

instructions are read and understood and that you have all the

necessary components before commencing installation. Failure to

install the product in accordance with these instructions may adversely

aect the warranty terms and conditions. Do not undertake any part

of this installation unless you are qualified to do so. Prior to starting,

ensure that you are familiar with the necessary plumbing and electrical

regulations and legislation required to install the product correctly and

safely.

The Quartz™ Electric is supplied with universal fittings intended to

secure the unit to a suitable wall.

•

!

Introduction

Quartz Electric is a surface mounted instantaneous electric shower unit which is

available in a choice of performance ratings – 8.5kW and 9.5kW available in

White/chrome and 8.5kW, 9.5kW and 10.5kW available in Satin chrome and

Graphite/chrome.

Quartz Electric’s patented Over Temperature Protection (OTP) device ensures safer

comfortable showering whilst the shower provides endless economical showering as it

imposes no demand on stored hot water.

Quartz Electric is supplied with a 2 year guarantee.

If you have any questions at any stage during installation please contact the Aqualisa

customer helpline on 01959 560010 for advice.

Safety information

This product must be installed by a competent person in accordance with all relevant

current Water Supply Regulations.

ALL SHOWERS REQUIRING AN ELECTRICAL CONNECTION MUST BE INSTALLED BY

A QUALIFIED PERSON FOLLOWING THE LATEST REVISION OF BS 7671 (WIRING

REGULATIONS) AND CERTIFIED TO CURRENT BUILDING REGULATIONS.

WITH REFERENCE TO BUILDING REGULATION PART P, ANY NEW INSTALLATION

OR REPLACEMENT PRODUCT INSTALLATION WHICH IS NOT IDENTICAL TO THE

PRODUCT BEING REPLACED, THE CABLE SIZES, CIRCUIT PROTECTIVE DEVICES,

EARTH BONDING AND ALL OTHER REQUIREMENTS OF THE BUILDING REGULATION

MUST BE ASSESSED BY A (REGISTERED) QUALIFIED ELECTRICIAN AND INSTALLED

IN CONSIDERATION TO THE SITE CONDITIONS (see table below).

Cables which are chased into the wall must be protected by the use of conduit or

sheathing. Surface mounted cables must also be protected by a suitable approved

conduit.

Before removing the shower heater cover, ensure the heater is isolated from the

electric mains.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities or lack of experience and knowledge unless

they have been given initial supervision or instruction concerning the use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Quartz Electric is suitable for household use only.

Flushing

Some modern fluxes can be extremely corrosive and, if left in contact, will attack

the working parts of this unit. All soldering must be completed and the pipe work

thoroughly flushed out in accordance with current Water Supply Regulations prior to

connection of the product.

Important information

Connections

Quartz Electric is suitable for use with 15mm British Standard pipe and should be

connected using a 15mm compression fitting (not supplied). Quartz Electric is suitable

for top, bottom or rear entry pipe work and top bottom or rear entry cable. Supply

lines should be flushed clear of any debris prior to installation of the unit.

Isolating valves

A suitable full bore isolation valve must be fitted to the incoming supply in accordance

with the current Water Supply Regulations and our terms of warranty.

Siting

The Quartz Electric unit must be mounted on a flat, vertical finished wall with the hose

outlet pointing downwards. Any distortion of the back plate may result in the unit not

working. Spacers are provided fitted to the service tunnel to enable the unit to be

fitted to an uneven wall surface.

DO NOT tile up to or use sealants around the Quartz Electric unit. The shower is

spaced off the wall by integral pillars to allow air circulation around the unit.

The casing must not be sited where it is subjected to continuous spray from the

shower head.

The Quartz Electric should not be sited in any situation where it is likely to freeze.

! WARNING. DO NOT SWITCH THE SHOWER ON IF THERE IS A POSSIBILITY THAT

THE SHOWER COULD BE FROZEN. If you have switched the shower on, SWITCH OFF

IMMEDIATELY. Please refer to the trouble shooting guide overleaf.

Pressures

Check that the dynamic (running) water pressure to the Quartz Electric is adequate.

A pressure test adaptor is provided, fitted to the inside of the front cover. Follow the

pressure test adaptor fitting instructions opposite to ensure the water pressure to the

shower is within the minimum and maximum requirements.

Quartz Electric requires:

Max: 1.0MPa (10 bar)

Min: 0.09MPa (0.9 bar) at a flow rate of 8 litres per minute

The Quartz Electric shower is designed to control static pressure up to 1.0MPa (10 bar).

Where pressures are likely to exceed 1.0MPa (10 bar), a pressure reducing valve must

be fitted into the incoming mains supply. A setting of 0.3MPa (3 bar) is recommended.

It should be noted that daytime pressures approaching 8 bar can rise above the

stated maximum overnight. A suitable pressure reducing valve is available from

Aqualisa.

The use of other services connected to the water supply to the shower unit may cause

the water pressure to drop below the minimum required. This should therefore be

taken into consideration.

Pressure relief device (PRD)

To meet European standards, the shower unit features an integral pressure relief

device (PRD). The PRD provides a degree of shower unit protection should an excessive

build up of pressure occur within the shower.

DO NOT operate the shower with a damaged or kinked hose or blocked shower head,

as this can cause the PRD to operate. Failure to follow this instruction will invalidate

the product guarantee.

The shower will only function correctly with the hose and handset provided

(see shower head installation instructions overleaf). Failure to do so may result in the

operation of the PRD and will invalidate the product guarantee.

Please fully commission the shower prior to use following the shower commissioning

procedure detailed overleaf. Failure to do so could cause the PRD to operate and will

invalidate the product guarantee.

The shower unit must be sited over a bath or shower tray as in the event of the PRD

operating, water will drain from the bottom of the shower unit.

Inspection & maintenance

In the interests of safety, we recommend the Quartz Electric and its electrical

installation are checked by a qualified electrician at least every 2 years.

Cleaning the filter should only be completed by a qualified person. Please refer to the

instructions opposite of how to clean the filter.

After installation

Familiarise the end user with the Quartz Electric operation and hand them this guide.

Complete and post the Quartz Electric guarantee card and optional guarantee

extension agreement document.

Customer helpline

01959 560010

Got a query? Need a stockist? Our helpline is open

from 8.00am to 5.30pm Mondays to Thursdays

and 8.00am to 5.00pm on Fridays to answer any

questions, guide you through any aspect of your

shower installation or advise you of your local

stockist.

Product literature

0800 652 3669

Call our literature hotline to receive the latest

Aqualisa product brochure containing details of

our full range of domestic products. Commercial

product brochures are also available on request.

Website

www.aqualisa.co.uk

Visit our website for comprehensive product

information, details of your nearest stockist and

installers, technical advice and more.

Republic of Ireland

Our products are also available in the Republic

of Ireland. If you need any technical advice,

details of local stockists or have any other queries,

please phone:

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Components

Quartz Electric shower with adjustable height

head in White/chrome

Literature not shown.

Trouble shooting guide

Action

Check power supply, consult electrician

Turn flow control knob anticlockwise.

Ensure water is turned fully on at the mains and at

servicing valve in supply.

If so, DO NOT USE.

i) Switch off immediately at electrical isolating switch.

ii) Turn water off at servicing valve (if fitted) or at

stop cock.

iii) Contact our Customer Service Department.

Disconnect handset from hose and run the shower.

i) If water flows, then handset is blocked with scale or

debris. Clean the handset and spray plate thoroughly.

ii) If the water does not flow, remove the hose from the

shower outlet.

a) If the water flows, the hose is blocked. This could be

due to damage, severe kinking or even an obstruction.

Replace with a new hose.

b) If the water does not flow, there is a blockage in the

plumbing to the shower, the filter or the shower itself.

Contact our Customer Service Department if the

shower is considered to be the problem.

Remove the filter for inspection. PLEASE REFER TO

INSPECTION AND MAINTENANCE SECTION

Remove front cover and check operation of knob

Symptom

No flow or not

enough flow

Possible cause

Power failure (light

does not illuminate)

Water control knob is

turned fully clockwise.

Water turned off at

mains or servicing

valve.

SHOWER UNIT

SUSPECTED OF BEING

FROZEN.

There may be an

outlet blockage.

Blocked inlet filter

Restricted operation of

flow control knob

Flow adequate

but water too

cold

Water too hot

Water runs from

around hose

Poor spray

pattern

Water flow is too high

No power to unit

Second stage thermal

trip operated

Water flow too low

Spray plate blocked

with scale or debris.

Water pressure too low.

Pressure relief device

(PRD) has operated

due to excess pressure

build up.

Hose incorrectly fitted.

Water pressure to

shower is low or

unstable

Thermal cut-out is

operating, normally

making a ‘click’ sound

Scald protection device

has activated

Multi pattern handset

incorrectly set

Low water inlet

temperature

Low voltage

Reduce the flow by turning the water control knob

towards the hot temperature markings (clockwise) slowly

a) Check isolator switch is on

b) Check MCB or fuse at consumer unit

c) Check RCD (if fitted)

d) Check 230/240V at terminal block

(Electrician only)

This is a non serviceable part, shower must be replaced

a) Increase the flow by turning the water control knob

towards the cold temperature markings

(anticlockwise) slowly.

b) Ensure that the stop cock and servicing valve are

fully open. If so, ask the installer or the local water

authority to check that the running pressure is above

the minimum requirement (see Pressures section

overleaf). This may be apparent during periods of

high demand or when other outlets are used.

Clean the handset spray plate.

Check with the installer or local water authority

Turn off electrical isolating switch and water servicing

valve and contact our Customer services department.

Ensure hose washer is fitted and hose is connected

correctly and tightly

Check inlet requirements – see Pressures section, and

ensure no other main water devices are being used while

showering

Increase the flow by turning the water control knob in

the cold temperature direction (anticlockwise). Clean the

handset and spray plate.

Increase the flow by turning the water control knob in

the cold temperature direction (anticlockwise). Clean

the handset and spray plate.

Adjust spray plate to improve pattern

Flow rate will naturally be lower when the inlet

temperature is low, this applies to all electric showers

Consult electrician

Cleaning & maintenance

Your Quartz Electric unit should be cleaned using only a soft cloth and washing up liquid.

DO NOT USE ABRASIVE CLEANERS.

To reduce the requirement for chemical descaling in hard water areas, the shower head incorporates rub clean

teats. Any scale build up that may occur in any of the holes can be broken down by gently rubbing the flexible

tips of the jets during use. This procedure should be completed regularly, as often as once a week in some hard

water areas as scale build up can affect the spray pattern and cause the shower to perform poorly.

Should chemical descaling of the head become necessary, remove the shower head and fully immerse in a mild

proprietary descalent.

! IT IS IMPERATIVE THAT DESCALING IS CARRIED OUT STRICTLY IN ACCORDANCE WITH THE

MANUFACTURERS INSTRUCTIONS. SUBSTANCES THAT ARE NOT SUITABLE FOR PLASTICS AND

ELECTROPLATED SURFACES MUST NOT BE USED.

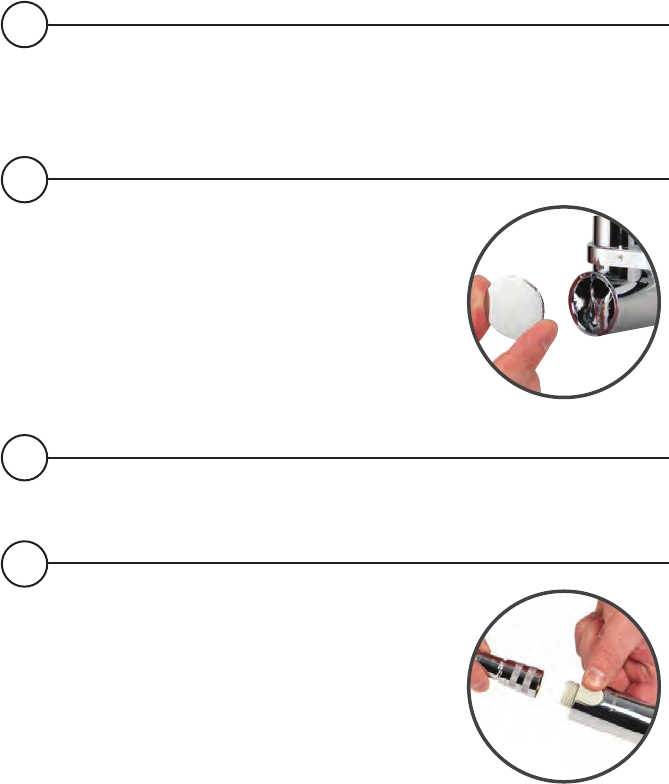

Cleaning the filter

Cleaning the filter should only be completed by a qualified person.

1. Turn the shower electrical isolating switch off.

2. Isolate the water supply to the shower.

3. Carefully remove fixing screws from the top and bottom of the front cover.

Carefully pull the front cover away from the unit ensuring the solenoid

connector block is detached.

4. Unscrew the two screws on the filter protective cover and remove the

filter assembly. (Fig.2).

5. Remove the filter assembly and clean as necessary. (Fig.3).

6. Refit the filter assembly and protective cover. Reassemble the unit in reverse of the above procedure.

Pressure test adaptor fitting instructions

Quartz Electric requires the following dynamic (running) water pressure:

Maximum: 1.0MPa (10bar)

Minimum: 0.09MPa (0.9bar) at a flow rate of 8lpm

To ensure the water pressure to the shower is adequate, we recommend adopting the following procedure:

1. Isolate the electrical supply to the shower.

2. Isolate the water supply to the shower.

3. Remove the fixing screws from the top and bottom of the front cover. Carefully detach the solenoid

connector and pull the front cover clear.

4. Remove the pressure test adaptor from the inside of the front cover.

5. Unscrew the two fixing screws on the filter and remove the filter assembly.

6. Replace the filter assembly with the pressure test adaptor and secure into place using the filter

assembly fixings.

7. Connect a pressure testing device to the adaptor (not supplied).

8. Ensuring the electrical supply remains isolated, turn on the water supply to the shower.

9. Push the solenoid piston up until water runs through to the shower unit.

10. Check the reading on the pressure testing device is within the minimum and maximum requirements

stated above.

11. Isolate the water supply to the shower.

12. Detach the pressure test device and remove the adaptor.

13. Refit the filter assembly and secure using the fixings.

14. Refit the pressure test adaptor into the fixing position within the front cover.

15. Reassemble the unit in reverse of the above procedure and turn on the water and electrical supplies to

the shower unit.

Quartz

Electric

Aqualisa Products Limited

The Flyer’s Way

Westerham Kent TN16 1DE

Customer helpline: 01959 560010

Brochure Hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Part No:438301 Issue 05 Nov18

Please note that calls may be recorded for training and quality purposes

The company reserves the right to alter, change or modify the product specifications without prior warning

® Registered Trademark Aqualisa Products Limited

The Waste Electrical and Electronic Equipment (Producer Responsibility) Regulation 2004

This product is outside the scope of the European Waste Electrical and Electronic Equipment Directive as interpreted within the UK.

In the UK this product can therefore be disposed of through commercial non-WEEE waste facilities.

The original manufacturer does not accept any liability under the WEEE directive within the UK.

In other EU countries the WEEE directive may apply and, at end of life, product must be disposed

of at a suitable WEEE recycling centre

Shower rating @ 240V

8.5kW

35.4A 39.6A 43.8A

40A 40A 45/50A

40/45A

Min cable

size mm

2

10

6

6 37 6 33 10 50

37 10 55 10 50

61 10 55 10 50

Max cable

run in m

Min cable

size mm

2

Max cable

run in m

Min cable

size mm

2

Max cable

run in m

40/45A 45A

9.5kW 10.5kW

Nominal current @ 240V

MCB rating

Conduit or trunking

Cartridge fuse

Installed in

insulated wall

Clipped direct

or buried in

uninsulated wall

Type

of

cable

run

Fig.2

Fig.3

Please place product serial

number label here.

Quartz Electric shower with adjustable

height head in Satin chrome

Quartz Electric shower with adjustable

height head in Graphite/chrome

Quartz Electric update July 11.qxd:Aquavalve 700 Thermo.qxd 30/6/11 22:56 Page 1

S

afety information

T

his appliance can be used by children aged from 3 years and above and

p

ersons with reduced physical, sensory or mental capabilities or lack of

e

xperience and knowledge if they have been given supervision or instruction

c

oncerning use of the appliance in a safe way and understand the hazards

i

nvolved.

C

hildren shall not play with the appliance.

C

leaning and user maintenance shall not be made by children without

s

upervision.

T

he spray head must be descaled regularly.

W

ARNING: Do not switch on if there is a possibility that the water in the

h

eater is frozen.

F

it only shower heads recommended by the manufacturer and never fit any

a

dditional device to restrict the water outlet flow.

T

he outlet must not be connected to any tap or fitting other than those

s

pecified.

T

his appliance is intended to be permanently connected to the water mains

a

nd not connected by a hose set.

A

suitable double pole isolation switch for supply disconnections must be

i

ncorporated in the fixed wiring circuit, in accordance with current wiring

r

ules. See Electrical Installation section for further details.his product must

b

e installed by a competent person in accordance with all relevant current

W

ater Supply Regulations.

A

LL SHOWERS REQUIRING AN ELECTRICAL CONNECTION MUST BE

I

NSTALLED BY A QUALIFIED PERSON FOLLOWING THE LATEST REVISION

O

F BS 7671 (WIRING REGULATIONS) AND CERTIFIED TO CURRENT

B

UILDING REGULATIONS.

W

ITH REFERENCE TO BUILDING REGULATION PART P, ANY NEW

I

NSTALLATION OR REPLACEMENT PRODUCT INSTALLATION WHICH IS

N

OT IDENTICAL TO THE PRODUCT BEING REPLACED, THE CABLE SIZES,

C

IRCUIT PROTECTIVE DEVICES, EARTH BONDING AND ALL OTHER

R

EQUIREMENTS OF THE BUILDING REGULATION MUST BE ASSESSED BY

A

(REGISTERED) QUALIFIED ELECTRICIAN AND INSTALLED IN

C

ONSIDERATION TO THE SITE CONDITIONS (see table below).

I

ntroduction

Q

uartz Electric is a surface mounted instantaneous electric shower unit which is available in a choice of performance

r

atings – 8.5kW and 9.5kW available in White/chrome and 8.5kW, 9.5kW and 10.5kW available in Satin chrome and

G

raphite/chrome.

Q

uartz Electric’s patented Over Temperature Protection (OTP) device ensures safer comfortable showering whilst the

s

hower provides endless economical showering as it imposes no demand on stored hot water.

Q

uartz Electric is supplied with a 2 year guarantee.

I

f you have any questions at any stage during installation please contact the Aqualisa customer helpline on

0

1959 560010 for advice.

C

ables which are chased into the wall must be protected by the use of conduit or sheathing. Surface mounted cables

m

ust also be protected by a suitable approved conduit.

B

efore removing the shower heater cover, ensure the heater is isolated from the electric mains.

Q

uartz Electric is suitable for household use only.

F

lushing

S

ome modern fluxes can be extremely corrosive and, if left in contact, will attack the working parts of this unit.

A

ll soldering must be completed and the pipe work thoroughly flushed out in accordance with current Water Supply

R

egulations prior to connection of the product.

Important information

Connections

Quartz Electric is suitable for use with 15mm British Standard pipe and should be connected using a 15mm

compression fitting (not supplied). Quartz Electric is suitable for top, bottom or rear entry pipe work and top

bottom or rear entry cable. Supply lines should be flushed clear of any debris prior to installation of the unit.

Isolating valves

A suitable full bore isolation valve must be fitted to the incoming supply in accordance with the current Water

Supply Regulations and our terms of warranty.

Siting

The Quartz Electric unit must be mounted on a flat, vertical finished wall with the hose outlet pointing

downwards. Any distortion of the back plate may result in the unit not working. Spacers are provided fitted to

the service tunnel to enable the unit to be fitted to an uneven wall surface.

DO NOT tile up to or use sealants around the Quartz Electric unit. The shower is spaced off the wall by integral

pillars t

oallow air circulation around the unit.

The casing must not be sited where it is subjected to continuous spray from the shower head.

The Quartz Electric should not be sited in any situation where it is likely to freeze.

! WARNING. DO NOT SWITCH THE SHOWER ON IF THERE IS A POSSIBILITY THAT THE SHOWER COULD BE

FROZEN. If you have switched the shower on, SWITCH OFF IMMEDIATELY. Please refer to the trouble shooting

guide overleaf.

Pressures

Check that the dynamic (running) water pressure to the Quartz Electric is adequate. A pressure test adaptor is

provided, fitted to the inside of the front cover. Follow the pressure test adaptor fitting instructions opposite to

ensure the water pressure to the shower is within the minimum and maximum requirements.

Quartz Electric requires:

Max: 1.0MPa (10 bar)

Min: 0.09MPa (0.9 bar) at a flow rate of 8 litres per minute

The Quartz Electric shower is designed to control static pressure up to 1.0MPa (10 bar). Where pre

ssures are likely

to exceed 1.0MPa (10 bar), a pressure reducing valve must be fitted into the incoming mains supply. A setting of

0.3MPa (3 bar) is recommended. It should be noted that daytime pressures approaching 8 bar can rise above the

stated maximum overnight. A suitable pressure reducing valve is available from Aqualisa.

The use of other services connected to the water supply to the shower unit may cause the water pressure to drop

below the minimum required. This shoul

dtherefore be taken into consideration.

Pressure relief device (PRD)

To meet European standards, the shower unit features an integral pressure relief device (PRD). The PRD provides

a degree of shower unit protection should an excessive build up of pressure occur within the shower.

DO NOT operate the shower with a damaged or kinked hose or blocked shower head, as this can cause the PRD

to operate. Failure to follow this instruction will invalidate

the guarantee.

The shower

will only function correctly with the hose and

handset provided (see shower head installation

instructions overleaf). Failure to do so may result in the

operation of the PRD and will invalidate the guarantee.

Please fully commission the shower prior to use following

the shower commissioning procedure detailed overleaf.

Failure to do so could cause the PRD to operate and will

invalidate the guarantee.

The shower unit must be sited over a bath or shower tray

as in the event of

the PRD operating, water will drain

from the bottom of the shower unit.

Inspection & maintenance

In the interests of safety, we recommend the Quartz

Electric and its electrical installation are checked by a

qualified electrician at least every 2 years.

Cleaning the filter should only be completed by a

qualified person. Please refer to the instructions opposite

of how to clean the filter.

After installation

Familiarise the end user with the Quartz Electric operation

and hand them this guide.

Complete and post the Quartz Electric guarantee card

and optional guarantee extension agreement document.

Declaration of Conformity

Aqualisa Products Limited declares that the Quartz

electric shower, complies with the essential requirements

and other relevant provisions of the Low Voltage Directive

(2014/35/EU) and the EMC Directive (2014/30/EU).

Customer helpline

01959 560010

Got a query? Need a stockist? Our helpline is

open from 8.30am to 5.00pm Monday to Friday

to answer any questions, guide you through any

aspect of your shower installation or advise you

of your local stockist.

Product literature

0800 652 3669

Call our literature hotline to receive the latest

Aqualisa product brochure containing details of

our full range of domestic products. Commercial

product brochures are also available on request.

Website

www.aqualisa.co.uk

Visit our website for comprehensive product

information, details of your nearest stockist and

installers, technical advice and more.

Republic of Ireland

Our products are also available in the Republic

of Ireland. If you need any technical advice,

details of local stockists or have any other queries,

please phone:

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Components

Quartz Electric shower with adjustable

height head in white/chrome

Literature not shown.

Trouble shooting guide

Action

Check power supply, consult electrician

Turn flow control knob anticlockwise.

Ensure water is turned fully on at the mains and at

servicing valve in supply.

If so, DO NOT USE.

i) Switch off immediately at electrical isolating switch.

ii) Turn water off at servicing valve (if fitted) or at

stop cock.

iii) Contact our Customer Service Departme

nt.

Disconnect handset from hose and run the shower.

i) If water flows, then handset is blocked with scale or

debris. Clean the handset and spray plate thoroughly.

ii) If the water does not flow, remove the hose from the

shower outlet.

a) If the water flows, the hose is blocked. This could be

due to damage, severe kinking or even an obstruction.

Replace with a new hose.

b) If the water does not flow, there is a blockage in the

plumbing to the shower, the filter or the shower itself.

Contact our Customer Service Department if the

shower is considered to be the problem.

Remove the filter for inspection. PLEASE REFER TO

INSPECTION AND MAINTENANCE SECTION

Remove front cover and check operation of knob

Symptom

No flow or not

enough flow

Possible cause

Power failure (light

does not illuminate)

Water control knob is

turned fully clockwise.

Water turned off at

mains or servicing

valve.

SHOWER UNIT

SUSPECTED OF BEING

FROZEN.

There may be an

outlet blockage.

Blocked inlet filter

Restricted operation of

flow control knob

Flow adequate

but water too

cold

Water too hot

Water runs from

around hose

Poor spray

pattern

Water flow is too high

No power to unit

Second stage thermal

trip operated

Water flow too low

Spray plate blocked

with scale or debris.

Water pressure too low.

Pressure relief device

(PRD) has operated

due to excess pressure

build up.

Hose incorrectly fitted.

Water pressure to

shower is low or

unstable

Thermal cut-out is

operating, normally

making a ‘click’ sound

Scald protection device

has activated

Multi pattern handset

incorrectly set

Low water inlet

temperature

Low voltage

Reduce the flow by turning the water control knob

towards the hot temperature markings (clockwise) slowly

a) Check isolator switch is on

b) Check MCB or fuse at consumer unit

c) Check RCD (if fitted)

d) Check 230/240V at terminal block

(Electrician only)

This is a non serviceable part, shower must be replaced

a) Increase

the flow by turning the water control knob

towards the cold temperature markings

(anticlockwise) slowly.

b) Ensure that the stop cock and servicing valve are

fully open. If so, ask the installer or the local water

authority to check that the running pressure is above

the minimum requirement (see Pressures section

overleaf). This may be apparent during periods of

high demand or when other outlets are used.

Clean the handset spray plate.

Check with the installer or local wate

r authority

Turn off electrical isolating switch and water servicing

valve and contact our Customer services department.

Ensure hose washer is fitted and hose is connected

correctly and tightly

Check inlet requirements – see Pressures section, and

ensure no other main water devices are being used while

showering

Increase the flow by turning the water control knob in

the cold temperature direction (anticlockwise). Clean the

handset and spray plate.

Increase the flow by

turning the water control knob in

the cold temperature direction (anticlockwise). Clean

the handset and spray plate.

Adjust spray plate to improve pattern

Flow rate will naturally be lower when the inlet

temperature is low, this applies to all electric showers

Consult electrician

Cleaning & maintenance

Your Quartz Electric unit should be cleaned using only a soft cloth and washing up liquid.

DO NOT USE ABRASIVE CLEANERS.

To reduce the requirement for chemical descaling in hard water areas, the shower head incorporates rub clean

teats. Any scale build up that may occur in any of the holes can be broken down by gently rubbing the flexible

tips of the jets during use. This procedure should be completed regularly, as often as once a week in some hard

water areas as scale build up can affect the spray pattern and cause the shower to perform poorly.

Should chemical descaling of the head become necessary, remove the shower head and fully immerse in a mild

proprietary descalent.

! IT IS IMPERATIVE THAT DESCALING IS CARRIED OUT STRICTLY IN ACCORDANCE WITH THE

MANUFACTURERS INSTRUCTIONS. SUBSTANCES THAT ARE NOT SUITABLE FOR PLASTICS AND

ELECTROPLATED SURFACES MUST NOT BE USED.

Cleaning the filter

Cleaning the filter should only be completed by a qualified person.

1. Turn the shower electrical isolating switch off.

2. Isolate the water supply to the shower.

3. Carefully remove fixing screws from the top and bottom of the front cover.

Carefully pull the front cover away from the unit ensuring the solenoid

connector block is detached.

4. Unscrew the two screws on the filter protective cover and remove the

filter assembly. (Fig.2).

5. Remove the filter assembly and clean as necessary. (Fig.3).

6. Refit the

filter assembly and protective cover. Reassemble the unit in reverse of the above procedure.

Pressure test adaptor fitting instructions

Quartz Electric requires the following dynamic (running) water pressure:

Maximum: 1.0MPa (10bar)

Minimum: 0.09MPa (0.9bar) at a flow rate of 8lpm

To ensure the water pressure to the shower is adequate, we recommend adopting the following procedure:

1. Isolate the electrical supply to the shower.

2. Isolate the water supply to the sho

wer.

3. Remove the fixing screws from the top and bottom of the front cover. Carefully detach the solenoid

connector and pull the front cover clear.

4. Remove the pressure test adaptor from the inside of the front cover.

5. Unscrew the two fixing screws on the filter and remove the filter assembly.

6. Replace the filter assembly with the pressure test adaptor and secure into place using the filter

assembly fixings.

7. Connect a pressure testing device to the adaptor (not suppli

ed).

8. Ensuring the electrical supply remains isolated, turn on the water supply to the shower.

9. Push the solenoid piston up until water runs through to the shower unit.

10. Check the reading on the pressure testing device is within the minimum and maximum requirements

stated above.

11. Isolate the water supply to the shower.

12. Detach the pressure test device and remove the adaptor.

13. Refit the filter assembly and secure using the fixings.

14. Refit the pressure test ad

aptor into the fixing position within the front cover.

15. Reassemble the unit in reverse of the above procedure and turn on the water and electrical supplies to

the shower unit.

Quartz

Electric

Installation guide

Aqualisa Products Limited

The Flyer’s Way

Westerham Kent TN16 1DE

Customer helpline: 01959 560010

Brochure Hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Part No:438301 Issue 2 Oct 07

Please note that calls may be recorded for training and quality purposes

The company reserves the right to alter, change or modify the product specifications without prior warning

® Registered Trademark Aqualisa Products Limited

The Waste Electrical and Electronic Equipment (Producer Responsibility) Regulation 2004

This product is outside the scope of the European Waste Electrical and Electronic Equipment Directive as interpreted within the UK.

In the UK this product can therefore be disposed of through commercial non-WEEE waste facilities.

The original manufacturer does not accept any

liability under the WEEE directive within the UK.

In other EU countries the WEEE directive may apply and, at end of life, product must be disposed

of at a suitable WEEE recycling centre

Shower rating @ 240V

8.5kW

35.4A 39.6A 43.8A

40A 40A 45/50A

40/45A

Min cable

size mm

2

10

6

6 37 6 33 10 50

37 10 55 10 50

61 10 55 10 50

Max cable

run in m

Min cable

size mm

2

Max cable

run in m

Min cable

size mm

2

Max cable

run in m

40/45A 45A

9.5kW 10.5kW

Nominal current @ 240V

MCB rating

Conduit or trunking

Cartridge fuse

Installed in

insulated wall

Clipped direct

or buried in

uninsulated wall

Type

of

cable

run

Fig.2

Fig.3

Please place product serial

number label here.

Quartz Electric shower with adjustable

height head in chrome

Quartz Electric update 20/2/07.qxd:Aquavalve 700 Thermo.qxd 14/9/18 12:15 Page 1

Aqualisa Products Limited

The Flyers Way

Westerham Kent TN16 1DE

Customer Helpline: 01959 560010

Brochure Hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Please place product serial

number label here.

Please note that calls may be recorded for training and

quality purposes.

The company reserves the right to alter, change or modify

the product specifications without prior warning.

™

Trademark of Aqualisa Products Limited.

Part No: 438301 Issue 06 Oct20

QUARTZ

™

ELECTRIC

INSTALLATION

GUIDE

Introduction

Quartz Electric is a surface mounted instantaneous electric shower unit which is

available in a choice of performance ratings – 8.5kW and 9.5kW available in

White/chrome and 8.5kW, 9.5kW and 10.5kW available in Satin chrome and

Graphite/chrome.

Quartz Electric’s patented Over Temperature Protection (OTP) device ensures safer

comfortable showering whilst the shower provides endless economical showering as it

imposes no demand on stored hot water.

Quartz Electric is supplied with a 2 year guarantee.

If you have any questions at any stage during installation please contact the Aqualisa

customer helpline on 01959 560010 for advice.

Safety information

This product must be installed by a competent person in accordance with all relevant

current Water Supply Regulations.

ALL SHOWERS REQUIRING AN ELECTRICAL CONNECTION MUST BE INSTALLED BY

A QUALIFIED PERSON FOLLOWING THE LATEST REVISION OF BS 7671 (WIRING

REGULATIONS) AND CERTIFIED TO CURRENT BUILDING REGULATIONS.

WITH REFERENCE TO BUILDING REGULATION PART P, ANY NEW INSTALLATION

OR REPLACEMENT PRODUCT INSTALLATION WHICH IS NOT IDENTICAL TO THE

PRODUCT BEING REPLACED, THE CABLE SIZES, CIRCUIT PROTECTIVE DEVICES,

EARTH BONDING AND ALL OTHER REQUIREMENTS OF THE BUILDING REGULATION

MUST BE ASSESSED BY A (REGISTERED) QUALIFIED ELECTRICIAN AND INSTALLED

IN CONSIDERATION TO THE SITE CONDITIONS (see table below).

Cables which are chased into the wall must be protected by the use of conduit or

sheathing. Surface mounted cables must also be protected by a suitable approved

conduit.

Before removing the shower heater cover, ensure the heater is isolated from the

electric mains.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities or lack of experience and knowledge unless

they have been given initial supervision or instruction concerning the use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Quartz Electric is suitable for household use only.

Flushing

Some modern fluxes can be extremely corrosive and, if left in contact, will attack

the working parts of this unit. All soldering must be completed and the pipe work

thoroughly flushed out in accordance with current Water Supply Regulations prior to

connection of the product.

Important information

Connections

Quartz Electric is suitable for use with 15mm British Standard pipe and should be

connected using a 15mm compression fitting (not supplied). Quartz Electric is suitable

for top, bottom or rear entry pipe work and top bottom or rear entry cable. Supply

lines should be flushed clear of any debris prior to installation of the unit.

Isolating valves

A suitable full bore isolation valve must be fitted to the incoming supply in accordance

with the current Water Supply Regulations and our terms of warranty.

Siting

The Quartz Electric unit must be mounted on a flat, vertical finished wall with the hose

outlet pointing downwards. Any distortion of the back plate may result in the unit not

working. Spacers are provided fitted to the service tunnel to enable the unit to be

fitted to an uneven wall surface.

DO NOT tile up to or use sealants around the Quartz Electric unit. The shower is

spaced off the wall by integral pillars to allow air circulation around the unit.

The casing must not be sited where it is subjected to continuous spray from the

shower head.

The Quartz Electric should not be sited in any situation where it is likely to freeze.

! WARNING. DO NOT SWITCH THE SHOWER ON IF THERE IS A POSSIBILITY THAT

THE SHOWER COULD BE FROZEN. If you have switched the shower on, SWITCH OFF

IMMEDIATELY. Please refer to the trouble shooting guide overleaf.

Pressures

Check that the dynamic (running) water pressure to the Quartz Electric is adequate.

A pressure test adaptor is provided, fitted to the inside of the front cover. Follow the

pressure test adaptor fitting instructions opposite to ensure the water pressure to the

shower is within the minimum and maximum requirements.

Quartz Electric requires:

Max: 1.0MPa (10 bar)

Min: 0.09MPa (0.9 bar) at a flow rate of 8 litres per minute

The Quartz Electric shower is designed to control static pressure up to 1.0MPa (10 bar).

Where pressures are likely to exceed 1.0MPa (10 bar), a pressure reducing valve must

be fitted into the incoming mains supply. A setting of 0.3MPa (3 bar) is recommended.

It should be noted that daytime pressures approaching 8 bar can rise above the

stated maximum overnight. A suitable pressure reducing valve is available from

Aqualisa.

The use of other services connected to the water supply to the shower unit may cause

the water pressure to drop below the minimum required. This should therefore be

taken into consideration.

Pressure relief device (PRD)

To meet European standards, the shower unit features an integral pressure relief

device (PRD). The PRD provides a degree of shower unit protection should an excessive

build up of pressure occur within the shower.

DO NOT operate the shower with a damaged or kinked hose or blocked shower head,

as this can cause the PRD to operate. Failure to follow this instruction will invalidate

the product guarantee.

The shower will only function correctly with the hose and handset provided

(see shower head installation instructions overleaf). Failure to do so may result in the

operation of the PRD and will invalidate the product guarantee.

Please fully commission the shower prior to use following the shower commissioning

procedure detailed overleaf. Failure to do so could cause the PRD to operate and will

invalidate the product guarantee.

The shower unit must be sited over a bath or shower tray as in the event of the PRD

operating, water will drain from the bottom of the shower unit.

Inspection & maintenance

In the interests of safety, we recommend the Quartz Electric and its electrical

installation are checked by a qualified electrician at least every 2 years.

Cleaning the filter should only be completed by a qualified person. Please refer to the

instructions opposite of how to clean the filter.

After installation

Familiarise the end user with the Quartz Electric operation and hand them this guide.

Complete and post the Quartz Electric guarantee card and optional guarantee

extension agreement document.

Customer helpline

01959 560010

Got a query? Need a stockist? Our helpline is open

from 8.00am to 5.30pm Mondays to Thursdays

and 8.00am to 5.00pm on Fridays to answer any

questions, guide you through any aspect of your

shower installation or advise you of your local

stockist.

Product literature

0800 652 3669

Call our literature hotline to receive the latest

Aqualisa product brochure containing details of

our full range of domestic products. Commercial

product brochures are also available on request.

Website

www.aqualisa.co.uk

Visit our website for comprehensive product

information, details of your nearest stockist and

installers, technical advice and more.

Republic of Ireland

Our products are also available in the Republic

of Ireland. If you need any technical advice,

details of local stockists or have any other queries,

please phone:

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Components

Quartz Electric shower with adjustable height

head in White/chrome

Literature not shown.

Trouble shooting guide

Action

Check power supply, consult electrician

Turn flow control knob anticlockwise.

Ensure water is turned fully on at the mains and at

servicing valve in supply.

If so, DO NOT USE.

i) Switch off immediately at electrical isolating switch.

ii) Turn water off at servicing valve (if fitted) or at

stop cock.

iii) Contact our Customer Service Department.

Disconnect handset from hose and run the shower.

i) If water flows, then handset is blocked with scale or

debris. Clean the handset and spray plate thoroughly.

ii) If the water does not flow, remove the hose from the

shower outlet.

a) If the water flows, the hose is blocked. This could be

due to damage, severe kinking or even an obstruction.

Replace with a new hose.

b) If the water does not flow, there is a blockage in the

plumbing to the shower, the filter or the shower itself.

Contact our Customer Service Department if the

shower is considered to be the problem.

Remove the filter for inspection. PLEASE REFER TO

INSPECTION AND MAINTENANCE SECTION

Remove front cover and check operation of knob

Symptom

No flow or not

enough flow

Possible cause

Power failure (light

does not illuminate)

Water control knob is

turned fully clockwise.

Water turned off at

mains or servicing

valve.

SHOWER UNIT

SUSPECTED OF BEING

FROZEN.

There may be an

outlet blockage.

Blocked inlet filter

Restricted operation of

flow control knob

Flow adequate

but water too

cold

Water too hot

Water runs from

around hose

Poor spray

pattern

Water flow is too high

No power to unit

Second stage thermal

trip operated

Water flow too low

Spray plate blocked

with scale or debris.

Water pressure too low.

Pressure relief device

(PRD) has operated

due to excess pressure

build up.

Hose incorrectly fitted.

Water pressure to

shower is low or

unstable

Thermal cut-out is

operating, normally

making a ‘click’ sound

Scald protection device

has activated

Multi pattern handset

incorrectly set

Low water inlet

temperature

Low voltage

Reduce the flow by turning the water control knob

towards the hot temperature markings (clockwise) slowly

a) Check isolator switch is on

b) Check MCB or fuse at consumer unit

c) Check RCD (if fitted)

d) Check 230/240V at terminal block

(Electrician only)

This is a non serviceable part, shower must be replaced

a) Increase the flow by turning the water control knob

towards the cold temperature markings

(anticlockwise) slowly.

b) Ensure that the stop cock and servicing valve are

fully open. If so, ask the installer or the local water

authority to check that the running pressure is above

the minimum requirement (see Pressures section

overleaf). This may be apparent during periods of

high demand or when other outlets are used.

Clean the handset spray plate.

Check with the installer or local water authority

Turn off electrical isolating switch and water servicing

valve and contact our Customer services department.

Ensure hose washer is fitted and hose is connected

correctly and tightly

Check inlet requirements – see Pressures section, and

ensure no other main water devices are being used while

showering

Increase the flow by turning the water control knob in

the cold temperature direction (anticlockwise). Clean the

handset and spray plate.

Increase the flow by turning the water control knob in

the cold temperature direction (anticlockwise). Clean

the handset and spray plate.

Adjust spray plate to improve pattern

Flow rate will naturally be lower when the inlet

temperature is low, this applies to all electric showers

Consult electrician

Cleaning & maintenance

Your Quartz Electric unit should be cleaned using only a soft cloth and washing up liquid.

DO NOT USE ABRASIVE CLEANERS.

To reduce the requirement for chemical descaling in hard water areas, the shower head incorporates rub clean

teats. Any scale build up that may occur in any of the holes can be broken down by gently rubbing the flexible

tips of the jets during use. This procedure should be completed regularly, as often as once a week in some hard

water areas as scale build up can affect the spray pattern and cause the shower to perform poorly.

Should chemical descaling of the head become necessary, remove the shower head and fully immerse in a mild

proprietary descalent.

! IT IS IMPERATIVE THAT DESCALING IS CARRIED OUT STRICTLY IN ACCORDANCE WITH THE

MANUFACTURERS INSTRUCTIONS. SUBSTANCES THAT ARE NOT SUITABLE FOR PLASTICS AND

ELECTROPLATED SURFACES MUST NOT BE USED.

Cleaning the filter

Cleaning the filter should only be completed by a qualified person.

1. Turn the shower electrical isolating switch off.

2. Isolate the water supply to the shower.

3. Carefully remove fixing screws from the top and bottom of the front cover.

Carefully pull the front cover away from the unit ensuring the solenoid

connector block is detached.

4. Unscrew the two screws on the filter protective cover and remove the

filter assembly. (Fig.2).

5. Remove the filter assembly and clean as necessary. (Fig.3).

6. Refit the filter assembly and protective cover. Reassemble the unit in reverse of the above procedure.

Pressure test adaptor fitting instructions

Quartz Electric requires the following dynamic (running) water pressure:

Maximum: 1.0MPa (10bar)

Minimum: 0.09MPa (0.9bar) at a flow rate of 8lpm

To ensure the water pressure to the shower is adequate, we recommend adopting the following procedure:

1. Isolate the electrical supply to the shower.

2. Isolate the water supply to the shower.

3. Remove the fixing screws from the top and bottom of the front cover. Carefully detach the solenoid

connector and pull the front cover clear.

4. Remove the pressure test adaptor from the inside of the front cover.

5. Unscrew the two fixing screws on the filter and remove the filter assembly.

6. Replace the filter assembly with the pressure test adaptor and secure into place using the filter

assembly fixings.

7. Connect a pressure testing device to the adaptor (not supplied).

8. Ensuring the electrical supply remains isolated, turn on the water supply to the shower.

9. Push the solenoid piston up until water runs through to the shower unit.

10. Check the reading on the pressure testing device is within the minimum and maximum requirements

stated above.

11. Isolate the water supply to the shower.

12. Detach the pressure test device and remove the adaptor.

13. Refit the filter assembly and secure using the fixings.

14. Refit the pressure test adaptor into the fixing position within the front cover.

15. Reassemble the unit in reverse of the above procedure and turn on the water and electrical supplies to

the shower unit.

Quartz

Electric

Aqualisa Products Limited

The Flyer’s Way

Westerham Kent TN16 1DE

Customer helpline: 01959 560010

Brochure Hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Part No:438301 Issue 05 Nov18

Please note that calls may be recorded for training and quality purposes

The company reserves the right to alter, change or modify the product specifications without prior warning

® Registered Trademark Aqualisa Products Limited

The Waste Electrical and Electronic Equipment (Producer Responsibility) Regulation 2004

This product is outside the scope of the European Waste Electrical and Electronic Equipment Directive as interpreted within the UK.

In the UK this product can therefore be disposed of through commercial non-WEEE waste facilities.

The original manufacturer does not accept any liability under the WEEE directive within the UK.

In other EU countries the WEEE directive may apply and, at end of life, product must be disposed

of at a suitable WEEE recycling centre

Shower rating @ 240V

8.5kW

35.4A 39.6A 43.8A

40A 40A 45/50A

40/45A

Min cable

size mm

2

10

6

6 37 6 33 10 50

37 10 55 10 50

61 10 55 10 50

Max cable

run in m

Min cable

size mm

2

Max cable

run in m

Min cable

size mm

2

Max cable

run in m

40/45A 45A

9.5kW 10.5kW

Nominal current @ 240V

MCB rating

Conduit or trunking

Cartridge fuse

Installed in

insulated wall

Clipped direct

or buried in

uninsulated wall

Type

of

cable

run

Fig.2

Fig.3

Please place product serial

number label here.

Quartz Electric shower with adjustable

height head in Satin chrome

Quartz Electric shower with adjustable

height head in Graphite/chrome

Quartz Electric update July 11.qxd:Aquavalve 700 Thermo.qxd 30/6/11 22:56 Page 1

S

afety information

T

his appliance can be used by children aged from 3 years and above and

p

ersons with reduced physical, sensory or mental capabilities or lack of

e

xperience and knowledge if they have been given supervision or instruction

c

oncerning use of the appliance in a safe way and understand the hazards

i

nvolved.

C

hildren shall not play with the appliance.

C

leaning and user maintenance shall not be made by children without

s

upervision.

T

he spray head must be descaled regularly.

W

ARNING: Do not switch on if there is a possibility that the water in the

h

eater is frozen.

F

it only shower heads recommended by the manufacturer and never fit any

a

dditional device to restrict the water outlet flow.

T

he outlet must not be connected to any tap or fitting other than those

s

pecified.

T

his appliance is intended to be permanently connected to the water mains

a

nd not connected by a hose set.

A

suitable double pole isolation switch for supply disconnections must be

i

ncorporated in the fixed wiring circuit, in accordance with current wiring

r

ules. See Electrical Installation section for further details.his product must

b

e installed by a competent person in accordance with all relevant current

W

ater Supply Regulations.

A

LL SHOWERS REQUIRING AN ELECTRICAL CONNECTION MUST BE

I

NSTALLED BY A QUALIFIED PERSON FOLLOWING THE LATEST REVISION

O

F BS 7671 (WIRING REGULATIONS) AND CERTIFIED TO CURRENT

B

UILDING REGULATIONS.

W

ITH REFERENCE TO BUILDING REGULATION PART P, ANY NEW

I

NSTALLATION OR REPLACEMENT PRODUCT INSTALLATION WHICH IS

N

OT IDENTICAL TO THE PRODUCT BEING REPLACED, THE CABLE SIZES,

C

IRCUIT PROTECTIVE DEVICES, EARTH BONDING AND ALL OTHER

R

EQUIREMENTS OF THE BUILDING REGULATION MUST BE ASSESSED BY

A

(REGISTERED) QUALIFIED ELECTRICIAN AND INSTALLED IN

C

ONSIDERATION TO THE SITE CONDITIONS (see table below).

I

ntroduction

Q

uartz Electric is a surface mounted instantaneous electric shower unit which is available in a choice of performance

r

atings – 8.5kW and 9.5kW available in White/chrome and 8.5kW, 9.5kW and 10.5kW available in Satin chrome and

G

raphite/chrome.

Q

uartz Electric’s patented Over Temperature Protection (OTP) device ensures safer comfortable showering whilst the

s

hower provides endless economical showering as it imposes no demand on stored hot water.

Q

uartz Electric is supplied with a 2 year guarantee.

I

f you have any questions at any stage during installation please contact the Aqualisa customer helpline on

0

1959 560010 for advice.

C

ables which are chased into the wall must be protected by the use of conduit or sheathing. Surface mounted cables

m

ust also be protected by a suitable approved conduit.

B

efore removing the shower heater cover, ensure the heater is isolated from the electric mains.

Q

uartz Electric is suitable for household use only.

F

lushing

S

ome modern fluxes can be extremely corrosive and, if left in contact, will attack the working parts of this unit.

A

ll soldering must be completed and the pipe work thoroughly flushed out in accordance with current Water Supply

R

egulations prior to connection of the product.

Important information

Connections

Quartz Electric is suitable for use with 15mm British Standard pipe and should be connected using a 15mm

compression fitting (not supplied). Quartz Electric is suitable for top, bottom or rear entry pipe work and top

bottom or rear entry cable. Supply lines should be flushed clear of any debris prior to installation of the unit.

Isolating valves

A suitable full bore isolation valve must be fitted to the incoming supply in accordance with the current Water

Supply Regulations and our terms of warranty.

Siting

The Quartz Electric unit must be mounted on a flat, vertical finished wall with the hose outlet pointing

downwards. Any distortion of the back plate may result in the unit not working. Spacers are provided fitted to

the service tunnel to enable the unit to be fitted to an uneven wall surface.

DO NOT tile up to or use sealants around the Quartz Electric unit. The shower is spaced off the wall by integral

pillars t

oallow air circulation around the unit.

The casing must not be sited where it is subjected to continuous spray from the shower head.

The Quartz Electric should not be sited in any situation where it is likely to freeze.

! WARNING. DO NOT SWITCH THE SHOWER ON IF THERE IS A POSSIBILITY THAT THE SHOWER COULD BE

FROZEN. If you have switched the shower on, SWITCH OFF IMMEDIATELY. Please refer to the trouble shooting

guide overleaf.

Pressures

Check that the dynamic (running) water pressure to the Quartz Electric is adequate. A pressure test adaptor is

provided, fitted to the inside of the front cover. Follow the pressure test adaptor fitting instructions opposite to

ensure the water pressure to the shower is within the minimum and maximum requirements.

Quartz Electric requires:

Max: 1.0MPa (10 bar)

Min: 0.09MPa (0.9 bar) at a flow rate of 8 litres per minute

The Quartz Electric shower is designed to control static pressure up to 1.0MPa (10 bar). Where pre

ssures are likely

to exceed 1.0MPa (10 bar), a pressure reducing valve must be fitted into the incoming mains supply. A setting of

0.3MPa (3 bar) is recommended. It should be noted that daytime pressures approaching 8 bar can rise above the

stated maximum overnight. A suitable pressure reducing valve is available from Aqualisa.

The use of other services connected to the water supply to the shower unit may cause the water pressure to drop

below the minimum required. This shoul

dtherefore be taken into consideration.

Pressure relief device (PRD)

To meet European standards, the shower unit features an integral pressure relief device (PRD). The PRD provides

a degree of shower unit protection should an excessive build up of pressure occur within the shower.

DO NOT operate the shower with a damaged or kinked hose or blocked shower head, as this can cause the PRD

to operate. Failure to follow this instruction will invalidate

the guarantee.

The shower

will only function correctly with the hose and

handset provided (see shower head installation

instructions overleaf). Failure to do so may result in the

operation of the PRD and will invalidate the guarantee.

Please fully commission the shower prior to use following

the shower commissioning procedure detailed overleaf.

Failure to do so could cause the PRD to operate and will

invalidate the guarantee.

The shower unit must be sited over a bath or shower tray

as in the event of

the PRD operating, water will drain

from the bottom of the shower unit.

Inspection & maintenance

In the interests of safety, we recommend the Quartz

Electric and its electrical installation are checked by a

qualified electrician at least every 2 years.

Cleaning the filter should only be completed by a

qualified person. Please refer to the instructions opposite

of how to clean the filter.

After installation

Familiarise the end user with the Quartz Electric operation

and hand them this guide.

Complete and post the Quartz Electric guarantee card

and optional guarantee extension agreement document.

Declaration of Conformity

Aqualisa Products Limited declares that the Quartz

electric shower, complies with the essential requirements

and other relevant provisions of the Low Voltage Directive

(2014/35/EU) and the EMC Directive (2014/30/EU).

Customer helpline

01959 560010

Got a query? Need a stockist? Our helpline is

open from 8.30am to 5.00pm Monday to Friday

to answer any questions, guide you through any

aspect of your shower installation or advise you

of your local stockist.

Product literature

0800 652 3669

Call our literature hotline to receive the latest

Aqualisa product brochure containing details of

our full range of domestic products. Commercial

product brochures are also available on request.

Website

www.aqualisa.co.uk

Visit our website for comprehensive product

information, details of your nearest stockist and

installers, technical advice and more.

Republic of Ireland

Our products are also available in the Republic

of Ireland. If you need any technical advice,

details of local stockists or have any other queries,

please phone:

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Components

Quartz Electric shower with adjustable

height head in white/chrome

Literature not shown.

Trouble shooting guide

Action

Check power supply, consult electrician

Turn flow control knob anticlockwise.

Ensure water is turned fully on at the mains and at

servicing valve in supply.

If so, DO NOT USE.

i) Switch off immediately at electrical isolating switch.

ii) Turn water off at servicing valve (if fitted) or at

stop cock.

iii) Contact our Customer Service Departme

nt.

Disconnect handset from hose and run the shower.

i) If water flows, then handset is blocked with scale or

debris. Clean the handset and spray plate thoroughly.

ii) If the water does not flow, remove the hose from the

shower outlet.

a) If the water flows, the hose is blocked. This could be

due to damage, severe kinking or even an obstruction.

Replace with a new hose.

b) If the water does not flow, there is a blockage in the

plumbing to the shower, the filter or the shower itself.

Contact our Customer Service Department if the

shower is considered to be the problem.

Remove the filter for inspection. PLEASE REFER TO