40RM/RMS

Packaged Air-Handling Units

50/60 Hz

6 to 30 Nominal Tons (21 to 105 kW)

Features / Benefits

· Multiposition designcan be installed

horizontally or vertically without

modification

·

Standard double skin units for a

better indoor air quality (IAQ)

·

Polyester powder painted zinc coated

steel panels provide additional protec-

tion against rusting & discoloration

in areas with high UV factor

· High-static design meets a wider

range of applications than competi-

tive packagedair handler lines

· Economizeraccessory provides ven-

tilation air and ``free'' cooling

· Cooling coils with mechanically-

bonded fins provide peak heat

transfer

· Standardfactory-installed thermo-

static expansion valves(TXVs) on

40RM

units

·

Standard sloped

drain pans

·

1" WASHABLE filters having frontal

access to remove them

·

Easy installation and maintenance;

removal of one sidepanel allows

access to serviceable components;

external piping connections

The 40RM Seriesis your bestchoice

for packagedair handlers.Model

40RM

units have direct-

expansion coils

and

model 40RMS

units have chilled water

coils.

All mod

els offer excellent fan

performance,

a unique combination of

indoor air

quality features, easy

install-

ation, and

affordable prices. Their vers-

atility and state-of-the-art featureswill

pro

vide economical performance now

and in the future.

Product Data

40RM007S-012S

40RMS008S-012S

40RM014S-034S

40RMS014S-034S

40RM-05PD 2011

40RM/RMS

Indoor air quality features:

The unique combination of features

in the 40RM Series air handlers en-

suresthat clean, fresh, conditioned air

is deliveredto the occupied space.

Cooling coils prevent the build-up

of humidity in the room, even during

part-load conditions. Unit sizes of

10 tons and above feature dual-circuit

face-splitcoils.

1 inch (25.4 mm) WASHABLE

air filters

remove dust and airborne

particles

from the occupied space.

Standard double skin units provide

an excellent resistance from the

air-borne particles off the insulation

thus maintaining an excellent indoor

air quality (IAQ).

Pitched drain pan can be adjusted

for a right- or left-hand connection to

provide positive drainage and prevent

standing condensate.

Accessory economizer can provide

ventilation air to improve indoor air

quality. When usedwith CO

2

sensors,

the economizer admits fresh outdoor

air to replace stale, recirculated

indoor

air.

Economy

The 40RM Series packaged air

handlers have low initial costs, and

they continue to savemoney by pro-

viding reducedinstallation expense

and energy-efficient performance.

Table of contents

Quick installation is ensuredby the

multiposition design. Units can be

installedin either the horizontal or

vertical (upflow) configuration without

modifications. All units have drain-

pan connectionson both sides,and

pans can be pitched for right- or left-

hand operation with a simple ad-

justment. Fan motors and contactors

are prewired and TXVs are factory-

installedon 40RM models.

High efficiency, precision-

balanced

fans minimize air turbulence, surging

and unbalanced operation, thereby

cutting operating

expenses.

Economizer accessory precisely

controls the blend of outdoor air and

room air to achievecomfort levels.

When the outsideair enthalpy is suit-

able, outside air damperscan fully

open to provide ``free'' cooling.

Rugged dependability

Polyester powder painted (zinc coated)

panels provide excellent resistance to

corrosion and also protect the colour

in the areas where ultra-violet (UV)

radiation factor is high.

Mechanically

bonded coil fins pro-

vide improved heat transfer.

Galvanized steel fan

housings

are

securely mounted to a die-formed

galvanized steel deck.

Rugged pillow-block bearings

(014-034 sizes) are securely fas-

tened to the solid steel fan shaft with

split collets and clamp locking devices.

Page

Smaller unit size shave spider-type

bearings.

Coil flexibility

Model 40RM (direct- expansion coils)

and 40RMS (chilled water coils) have

galvanized steel casings; inlet and

outlet connections are external & on

the same end.

Chilled water coils have

1/2

in.

(12.7 mm) diameter copper tubesme-

chanicallybonded to aluminum sine-

wave fins. All coils have non-ferrous

headers.

Direct expansion (DX) coils are

designed for use with Refrigerant 22

and have copper tubes mechani-

cally bonded to aluminum sine-wave

fins. Direct-expansioncoils include

matched, factory-installed thermostatic

expansion valves(TXVs) with matching

distributor nozzles.

Easier installation and service:

The multi-position designand com-

ponent layout help you to get the unit

installedand running quickly. The DX

coils have factory-installedTXVs with

matching distributor nozzles.Units can

be converted from horizontal to verti-

cal operation by simply reposition-

ing the unit. Drain pan connections

are duplicated on both sidesof the

unit. The filters, motor, drive, TXVs,

and coil connections are easilyaccessed

by removing a single side panels.

Features/Benefits ................................................. 1,2

Model Number Nomenclature ....................................... 3

PhysicalData ..................................................... 4-7

Options and Accessories......................................... 8-10

Dimensions ..................................................... 11-20

Selection Procedure ............................................. 21,22

Performance Data ............................................... 23-39

ElectricalData .................................................. 40-46

Typical Piping and Wiring ........................................ 47-50

Application Data ................................................ 51-59

Guide Specifications ............................................. 60,61

2

Model number nomenclature

40RM-016SD B5 0 1 ED

40RM Commercial Packaged

Air Handler

Cooling Coil

- Direct Expansion

S Chilled Water

Nominal Capacity Tons (kW)

007 6 (21) 016 15 (52)

008 7-1/2 (26) 024 20 (70)

010 8-1/2 (29) 028 25 (87)

012 10 (35) 034 30 (105)

014 12-1/2 (43)

S: SAMCO

D: Double Skin

Expansion Device

- None (40RMS)

B Thermostatic Expansion Valves (40RM )

Voltage Designation (V-Ph-Hz)

3 208/230-1-60 (007-010 sizes only)

5 208/230-3-60

6 208/230/460-3-60 (all sizes 007-014; size 016

except YC and WD options)

460-3-60 (sizes 016 with YC or WD options and

all size 024-034 units)

8 230-3-50

9 400-3-50

Revision Number

0 Original Model

Factory-Installed Options

ED

FD

Painted, Standard Motor and

Standard Drive

Painted, Standard Motor and

Medium-Static Drive (Not available

for 028 size for 60 Hz units and

016-028 for 50 Hz units)

RD

WD

Painted, Alternate Motor and

Medium-Static Drive (Available for

50 Hz sizes 016,024,028 and

60 Hz size 028 only)

Painted, Alternate Motor and

High-Static Drive

Packaging

1 Standard Domestic

3 Export

40RM/RMS

²YC and WD option codes for all 034 size units and 008, 010 units with 208/230-1-60 power designate

standard motor and high-static drive.

NOTE: See the following table for the sizes available for each unit.

UNIT SIZE AVAILABILITY

UNIT 007 008 010 012 014 016 024 028 034

40RM XX XXXXXX

40RMS

XXXXXXXX

3

Physical data

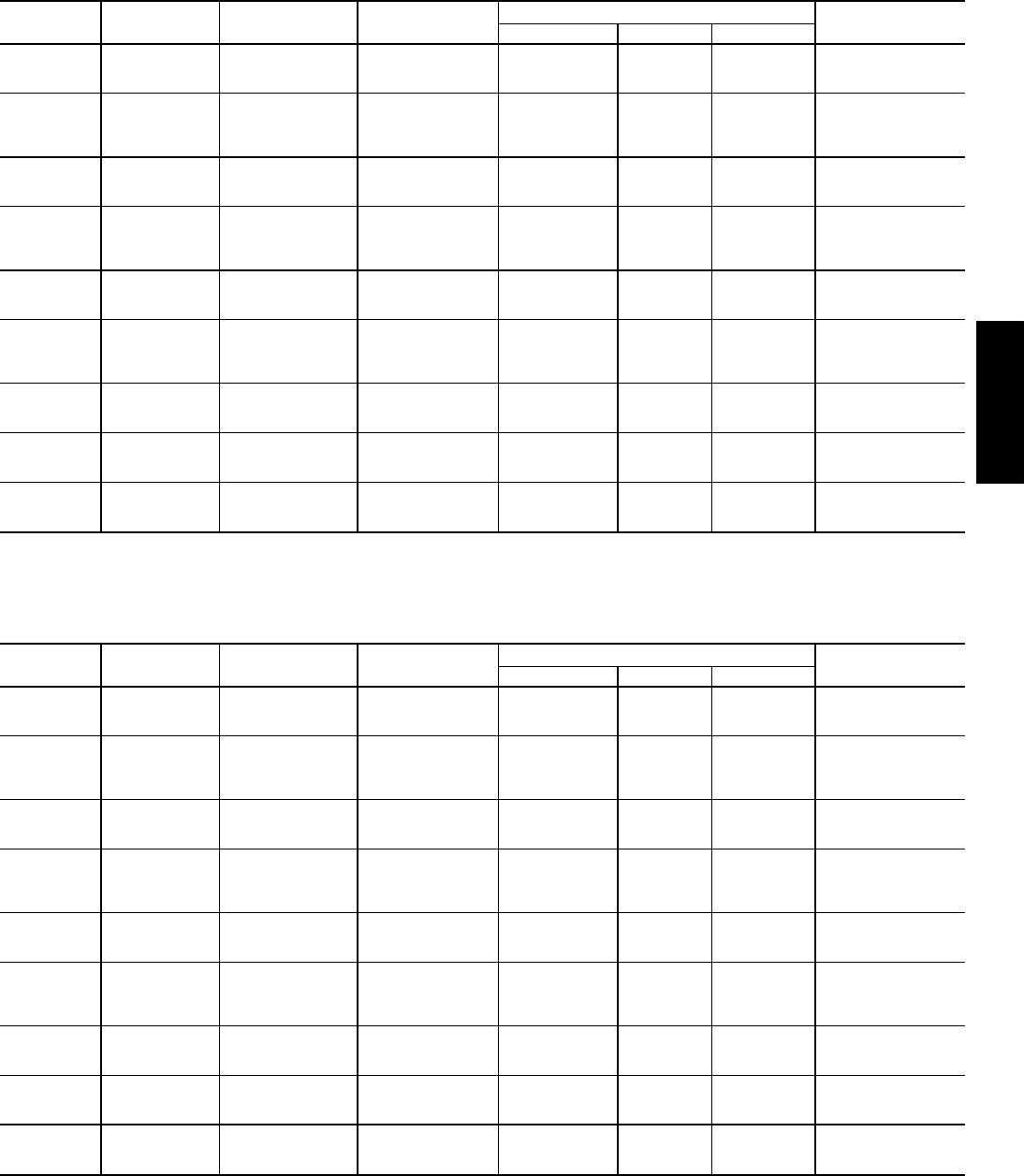

40RM - ENGLISH

40RM/RMS

UNIT 40RM 007SD 008SD 012SD 014SD 016SD 024SD 028SD 034SD

NOMINAL CAPACITY (Tons) 12

1/2

7

1

/

2

6 10 15 20 25 30

OPERATING WEIGHT (lb)

Base Unit (Double skin) with TXV 448 452 472 804 819 824 1188 1198

Plenum 97 97 97 140 140 140 180 180

FANS

Qty...Diam. (in.) 1...15 1...15 1...15 2...15 2...15 2...15 2...18 2...18

Nominal Airflow (cfm) 2400 3000 4000 5000 6000 8000 10,000 12,000

Airflow Range (cfm) 1800-3000 2250-3750 3000-5000 3750-6250 4500-7500 6000-10,000 7500-12,500 9000-15,000

Nominal Motor Hp (Standard Motor)*

208/230-1-60 1.3 2.4 - - - - - -

208/230-3-60 and 460-3-60 2.4 2.4 2.4 2.9 3.7 5.0 7.5 10.0

575-3-60 1.0 2.0 2.0 3.0 3.0 5.0 7.5 10.0

230-3-50, 400-3-50 2.4 2.4 2.9 2.9 2.9 5.0 7.5 10.0

Motor Speed (rpm)

208/230-1-60 1725 1725 - - - - - -

208/230-3-60 and 460-3-60 1725 1725 1725 1725 1725 1745 1745 1745

575-3-60 1725 1725 1725 1725 1725 1745 1755 1755

230-3-50, 400-3-50 1425

REFRIGERANT R-22

Operating charge (lb)

3.0 3.0 1.5/1.5 2.0/2.0 2.5/2.5 3.5/3.5 4.5/4.5 5.0/5.0

(approx per circuit)²

DIRECT-EXPANSION COIL Enhanced Copper Tubes, Aluminum Sine-Wave Fins

Max Working Pressure (psig) 435

Face Area (sq ft) 6.67 8.33 10.0 13.25 17.67 19.88 24.86 29.83

No. of Splits 1 1 2 2 2 2 2 2

Split Type...Percentage - - Face...50/50

No. of Circuits per Split 12 15 9 9 12 13 15 18

Rows...Fins/in. 3...15 3...15 3...17 3...15 3...15 3...17 3...15 3...15

STEAM COIL**

Max Working Pressure (psig at 400 F) 175

Total Face Area (sq ft) 6.67 6.67 6.67 13.33 13.33 13.33 15.0 15.0

Rows...Fins/in. 1...9 1...9 1...9 1...10 1...10 1...10 1...10 1...10

HOT WATER COIL**

Max Working Pressure (psig) 150

Total Face Area (sq ft) 6.67 6.67 6.67 13.33 13.33 13.33 15.0 15.0

Rows...Fins/in. 2...8.5 2...8.5 2...8.5 2...8.5 2...8.5 2...8.5 2...12.5 2...12.5

Water Volume

(gal) 8.3 13.9 14.3

(ft

3

) 1.1 1.85 1.90

PIPING CONNECTIONS

Quantity...Size (in.)

DX Coil - Suction (ODF) 1...1

1/8

1...1

1/8

2...1

1/8

2...1

1/8

2...1

1/8

2...1

1/8

2...1

3/8

2...1

3/8

DX Coil - Liquid Refrigerant (ODF) 1...

5/8

2...

5/8

Steam Coil, In (MPT) 1...2

1/2

1...2

1/2

Steam Coil, Out (MPT) 1...1

1/2

1...1

1/2

Hot Water Coil, In (MPT) 1...1

1/2

1...1

1/2

1...2

Hot Water Coil, Out (MPT) 1...1

1/2

1...1

1/2

1...2

Condensate (PVC) 1...1

1/4

ODM/1 IDF

FILTERS Washable - Factory Supplied

4...16 x 20 x 1 4...20 x 24 x 1

Quantity...Size (in.) 4...16 x 24 x 1

4...16 x 24 x 1 4...20 x 25 x 1

Access Location Front

LEGEND

DX - Direct Expansion

TXV - Thermostatic Expansion Valve

*Refer to alternate Fan Motor Data table, pages 52 and 53, for alternate motor data.

²Units are shipped without refrigerant charge.

**Please contact your local Carrier sales office for availability.

Please contact your local Carrier sales office for the weights of single skin units.

4

---

---

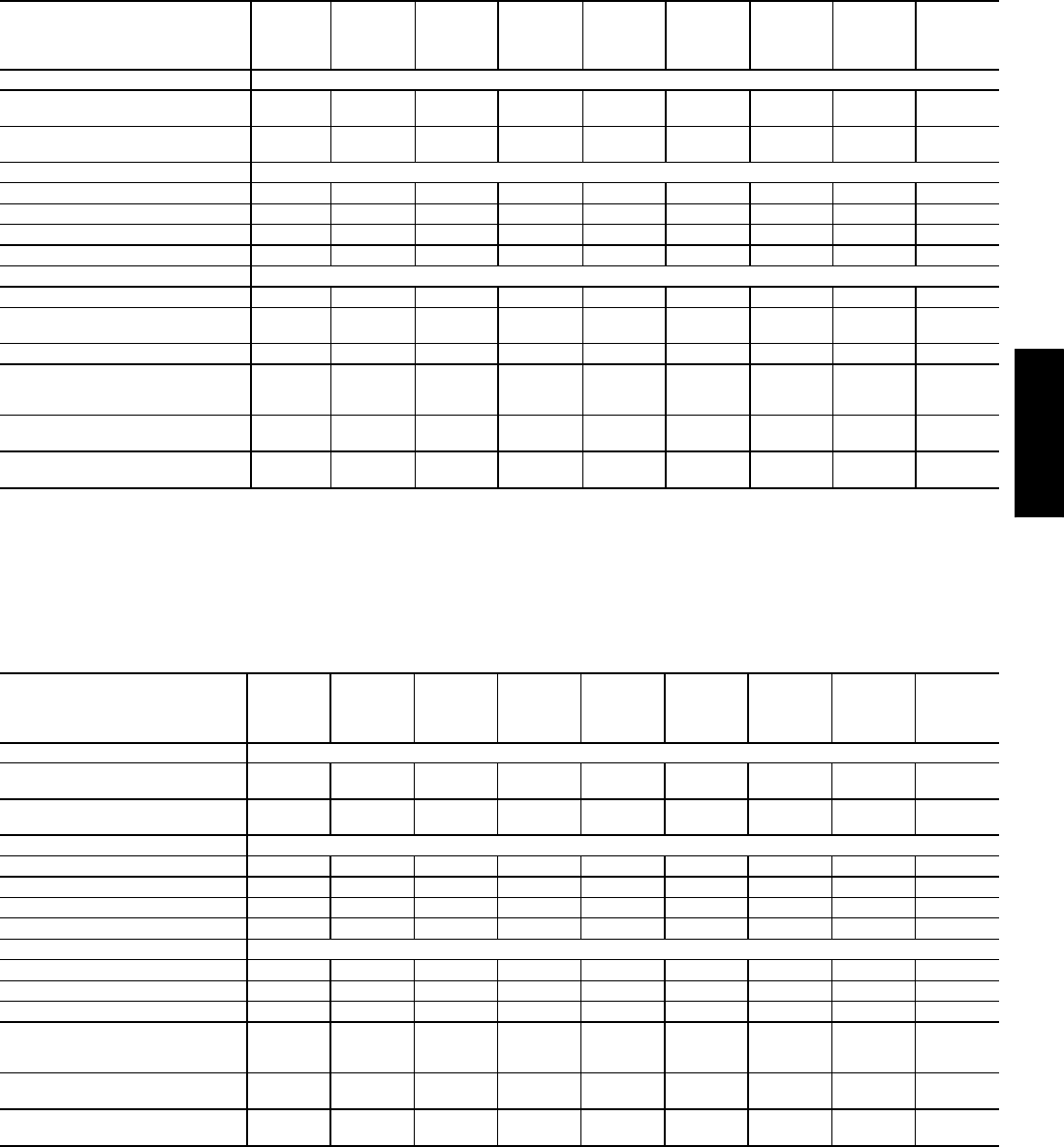

40RM - SI

UNIT 40RM 007SD 008SD 012SD 014SD 016SD 024SD 028SD 034SD

NOMINAL CAPACITY (kW) 21 26 35 43 52 70 87 105

OPERATING WEIGHT (kg)

Base Unit (Double skin) with TXV 203 205 214 364 371 373 538 542

Plenum 44 44 44 63 63 63 82 82

FANS

Qty...Diam. (mm) 1...381 1...381 1...381 2...381 2...381 2...381 2...457 2...457

Nominal Airflow (L/s) 1133 1604 1888 2360 2831 3775 4719 5663

Airflow Range (L/s) 850-1416 1203-2006 1416-2360 1770-2949 2124-3539 2831-4719 3539-5899 4247-7079

Nominal Motor kW (Standard Motor)*

208/230-1-60 0.97 1.79 - - - -

208/230-3-60 and 460-3-60 1.79 1.79 1.79 2.16 2.76 3.73 5.59 7.46

575-3-60 0.75 1.49 1.49 2.24 2.24 3.73 5.59 7.46

230-3-50, 400-3-50 1.79 1.79 2.16 2.16 2.16 3.73 5.59 7.46

Motor Speed (r/s)

208/230-1-60 28.8 28.8 - - - -

208/230-3-60 and 460-3-60 28.8 28.8 28.8 28.8 28.8 29.1 29.1 29.1

575-3-60 28.8 28.8 28.8 28.8 28.8 29.1 29.3 29.3

230-3-50, 400-3-50 23.8 23.8 23.8 23.8 23.8 23.8 23.8 23.8

REFRIGERANT R-22

Operating charge (kg)

1.36 1.36 0.68/0.68 0.90/0.90 1.13/1.13 1.59/1.59 2.04/2.04 2.27/2.27

(approx per circuit)²

DIRECT-EXPANSION COIL Enhanced Copper Tubes, Aluminum Sine-Wave Fins

Max Working Pressure (kPag) 2999

Face Area (sq m) 0.62 0.77 0.93 0.93 1.64 1.85 2.30 2.77

No. of Splits 11222222

No. of Circuits per Split 12 15 9 9 12 13 15 18

Split Type...Percentage - - Face...50/50

Rows...Fins/m 3...591 3...591 3...670 3...591 3...591 3...670 3...591 3...591

STEAM COIL***

Max Working Pressure (kPag at 204.4 C) 1207

Total Face Area (sq m) 0.62 0.62 0.62 1.24 1.24 1.24 1.39 1.39

Rows...Fins/m 1...355 1...355 1...355 1...394 1...394 1...394 1...394 1...394

HOT WATER COIL***

Max Working Pressure (kPag) 1034

Total Face Area (sq m) 0.62 0.62 0.62 1.24 1.24 1.24 1.39 1.39

Rows...Fins/m 2...335 2...335 2...335 2...335 2...335 2...335 2...493 2...493

Water Volume

(L) 31.4 52.6 54.1

(m

3

) 0.031 0.052 0.054

PIPING CONNECTIONS**

Quantity...Size (in.)

DX Coil - Suction (ODF) 1...1

1/8

1...1

1/8

2...1

1/8

2...1

1/8

2...1

1/8

2...1

1/8

2...1

3/8

2...1

3/8

DX Coil - Liquid Refrigerant (ODF) 1...

5/8

2...

5/8

Steam Coil, In (MPT) 1...2

1/2

1...2

1/2

Steam Coil, Out (MPT) 1...1

1/2

1...1

1/2

Hot Water Coil, In (MPT) 1...1

1/2

1...1

1/2

1...2

Hot Water Coil, Out (MPT) 1...1

1/2

1...1

1/2

1...2

Condensate (PVC) 1...1

1/4

ODM/1 IDF

FILTERS Washable - Factory Supplied

4...406 x 508 x 25.4 4...508 x 610 x 25.4

Quantity...Size 4...406 x 610 x 25.4

4...406 x 610 x 25.4 4...508 x 635 x 25.4

Access Location Front

LEGEND

DX - Direct Expansion

TXV - Thermostatic Expansion Valve

*Refer to Alternate Fan Motor Data table, pages 56 and 57, for alternate motor data.

²Units are shipped without refrigerant charge.

**All piping sizes are OD inches; equivalent sizes in millimeters follow:

***Please contact your local Carrier sales office for availability.

in. mm

5/8

15.9

1 25.4

1

1/8

28.6

1

1/4

31.8

1

3/8

34.9

1

1/2

38.1

2 50.8

2

1/8

54.0

2

1/2

63.5

40RM/RMS

Please contact your local Carrier sales office for the weights of single skin units.

5

Physical data (cont)

40RMS - ENGLISH

40RM/RMS

UNIT 40RMS 008SD 010SD 012SD 014SD 016SD 024SD 028SD 034SD

NOMINAL CAPACITY (Tons) 7

1/2

8

1/2

12

1/2

10 15 20 25 30

OPERATING WEIGHT (lb)

Base Unit (Double skin) 457 458 458 795 811 817 1203 1210

Plenum 97 97 97 140 140 140 180 180

FANS

Qty...Diam. (in.) 1...15 1...15 1...15 2...15 2...15 2...15 2...18 2...18

Nominal Airflow (cfm) 3000 3400 4000 5000 6000 8000 10,000 12,000

Airflow Range (cfm) 2250-3750 2250-4250 3000-5000 3750-6250 4500-7500 6000-10,000 7500-12,500 9000-15,000

Nominal Motor Hp

(Standard Motor)*

208/230-1-60 2.4 2.4 - - - - - -

208/230-3-60 and 460-3-60 2.4 2.4 2.4 2.9 3.7 5.0 7.5 10.0

575-3-60 2.0 2.0 2.0 3.0 3.0 5.0 7.5 10.0

230-3-50, 400-3-50 2.4 2.4 2.9 2.9 2.9 5.0 7.5 10.0

Motor Speed (rpm)

208/230-1-60 1725 1725 - - - - - -

208/230-3-60 and 460-3-60 1725 1725 1725 1725 1725 1745 1745 1745

575-3-60 1725 1725 1725 1725 1725 1745 1755 1755

230-3-50, 400-3-50 1425

CHILLED WATER COIL Enhanced Copper Tubes, Aluminum Sine-Wave Fins

Max Working Pressure (psig) 435

Face Area (sq ft) - Upper 8.3 9.0 9.8 8.3 8.3 11.0 12.4 15.5

Face Area (sq ft) - Lower - - - 5.5 8.3 8.3 12.4 12.4

Rows...Fins/in. 3...15

Water Volume

(gal) 3.0 3.3 3.5 4.7 5.6 6.4 8.9 9.9

(ft

3

) 0.40 0.47 0.46 0.63 0.75 0.85 1.19 1.32

STEAM COIL**

Max Working Pressure

175

(psig at 400 F)

Total Face Area (sq ft) 6.67 6.67 6.67 13.33 13.33 13.33 15.0 15.0

Rows...Fins/in. 1...9 1...9 1...9 1...10 1...10 1...10 1...10 1...10

HOT WATER COIL**

Max Working Pressure (in. wg) 150

Total Face Area (sq ft) 6.67 6.67 6.67 13.33 13.33 13.33 15.0 15.0

Rows...Fins/in. 2...8.5 2...8.5 2...8.5 2...8.5 2...8.5 2...8.5 2...12.5 2...12.5

Water Volume

(gal) 8.3 13.9 14.3

(ft

3

) 1.1 1.85 1.90

PIPING CONNECTIONS

Quantity...Size (in.)

Chilled Water - In 1...1

3/8

ODF 1...1

3/8

ODF 1...1

3/8

ODF 2...1

3/8

ODM 2...1

3/8

ODM 2...1

3/8

ODM 2...2

1/8

ODM 2...2

1/8

ODM

Chilled Water - Out 1...1

3/8

ODF 1...1

3/8

ODF 1...1

3/8

ODF 2...1

3/8

ODM 2...1

3/8

ODM 2...1

3/8

ODM 2...2

1/8

ODM 2...2

1/8

ODM

Steam Coil, In (MPT) 1...2

1/2

1...2

1/2

Steam Coil, Out (MPT) 1...1

1/2

1...1

1/2

Hot Water Coil, In (MPT) 1...1

1/2

1...1

1/2

1...2

Hot Water Coil, Out (MPT) 1...1

1/2

1...1

1/2

1...2

Condensate (PVC) 1...1

1/4

ODM/1 IDF

FILTERS Washable - Factory Supplied

4...16 x 20 x 1 4...20 x 24 x 1

Quantity...Size (in.) 4...16 x 24 x 1

4...16 x 24 x 1 4...20 x 25 x 1

Access Location Front

*Refer to the Alternate Fan Motor Data table, pages 52 and 53, for alternate motor data.

**Please contact your local Carrier sales office for availability.

Please contact your local Carrier sales office for the weights of single skin units.

6

---

---

40RMS - SI

UNIT 40RMS 008SD 010SD 012SD 014SD 016SD 024SD 028SD 034SD

NOMINAL CAPACITY (kW) 26 29 35 43 52 70 87 105

OPERATING WEIGHT (kg)

Base Unit (Double skin) 207 207 207 360 367 370 544 548

Plenum 44 44 44 63 63 63 82 82

FANS

Qty...Diam. (mm) 1...381 1...381 1...381 2...381 2...381 2...381 2...457 2...457

Nominal Airflow (L/s) 1416 1605 1888 2360 2831 3775 4719 5663

1062- 1204- 1416- 1770- 2124- 2831- 3539- 4247-

Airflow Range (L/s)

1770 2006 2360 2949 3539 4719 5899 7079

Nominal Motor kW

(Standard Motor)*

208/230-1-60 1.79 1.79 - - - -

208/230-3-60, 460-3-60 1.79 1.79 1.79 1.79 2.76 3.73 5.59 7.46

575-3-60 1.49 1.49 1.49 1.49 2.24 3.73 5.59 7.46

230-3-50, 400-3-50 1.79 1.79 2.16 2.16 2.16 3.73 5.59 7.46

Motor Speed (r/s)

208/230-1-60 28.8 28.8 - - - -

208/230-3-60, 460-3-60 28.8 28.8 28.8 28.8 28.8 29.1 29.1 29.1

575-3-60 28.8 28.8 28.8 28.8 28.8 29.1 29.3 29.3

230-3-50, 400-3-50 23.8 23.8 23.8 23.8 23.8 23.8 23.8 23.8

CHILLED WATER COIL

Max Working Pressure

2999

(kPag)

Face Area (sq m) - Upper 0.77 0.84 0.91 0.77 0.77 1.02 1.15 1.44

Face Area (sq m) - Lower - - - 0.51 0.77 0.77 1.15 1.15

Rows...Fins/m 3...591 3...591 3...591 3...591 3...591 3...591 3...591 3...591

Water Volume

(L) 11.4 12.5 13.2 17.8 21.2 24.2 33.7 37.5

(M

3

) 0.011 0.013 0.013 0.018 0.021 0.024 0.032 0.037

STEAM COIL**

Max Working Pressure

1207

(kPag at 204.4 C)

Total Face Area (sq m) 0.62 0.62 0.62 1.24 1.24 1.24 1.39 1.39

Rows...Fins/m 1...355 1...355 1...355 1...355 1...394 1...394 1...394 1...394

HOT WATER COIL**

Max Working Pressure

1034

(kPag)

Total Face Area (sq m) 0.62 0.62 0.62 1.24 1.24 1.24 1.39 1.39

Rows...Fins/m 2...335 2...335 2...335 2...335 2...335 2...335 2...493 2...493

Water Volume

(L) 31.4 52.6 54.1

(m

3

) 0.031 0.052 0.054

PIPING CONNECTIONS²

Quantity...Size (in.)

Chilled Water - In 1...1

3/8

ODF 1...1

3/8

ODF 2...1

3/8

ODF 2...1

3/8

ODM 2...1

3/8

ODM 2...1

3/8

ODM 2...2

1/8

ODM 2...2

1/8

ODM

Chilled Water - Out 1...1

3/8

ODF 1...1

3/8

ODF 2...1

3/8

ODF 2...1

3/8

ODM 2...1

3/8

ODM 2...1

3/8

ODM 2...2

1/8

ODM 2...2

1/8

ODM

Steam Coil, In (MPT) 1...2

1/2

1...2

1/2

Steam Coil, Out (MPT) 1...1

1/2

1...1

1/2

Hot Water Coil, In (MPT) 1...1

1/2

1...1

1/2

1...2

Hot Water Coil, Out (MPT) 1...1

1/2

1...1

1/2

1...2

Condensate (PVC) 1...1

1/4

ODM/1 IDF

FILTERS Washable - Factory Supplied

4...406 x 508 x 25.4 4...508 x 610 x 25.4

Quantity...Size (mm) 4...406 x 610 x 25.4

4...406 x 610 x 25.4 4...508 x 635 x 25.4

Access Location Front

40RM/RMS

*Refer to the Alternate Fan Motor Data table, pages 52 and 53, for alternate motor data.

²All piping sizes are OD inches; equivalent sizes in millimeters follow:

**Please contact your local Carrier sales office for availability.

in. mm

5/8

15.9

1 25.4

1

1/8

28.6

1

1/4

31.8

1

3/8

34.9

1

1/2

38.1

2 50.8

2

1/8

54.0

2

1/2

63.5

Please contact your local Carrier sales office for the weights of single skin units.

7

40RM/RMS

Options and accessories

Factory-installed options

Alternate fan motors and drives are availableto pro-

vide the widest possiblerange of performance.

Field-installed accessories

Two-row hot water coils have copper tubes mechani-

cally bonded to aluminum plate fins and non-ferrous

headers.

One-row steam coil has copper tubesand aluminumfins.

The Inner Distributing Tube (IDT) designprovides uniform

temperaturesacrossthecoil face.The steamcoil hasa broad

operating pressurerange; up to 175 psig (1207 kPag) at

400 F (204.4 C) and up to 300 psig (2069 kPag)at 300 F

(148.9 C). The IDT steamcoils are especiallysuitedto ap-

plications where sub-freezingair enters the unit.

Electric resistance heat coils havean open-wire design

and are mounted in a rigid frame. Safety cutouts for high

temperature conditions are standard. Terminal block for

single-point power connection is included.

Economizer (enthalpy contr olled) provides ventilation

air and ``free'' cooling if outside ambient temperature and

humidity are suitable. Can also be usedwith CO

2

sensors

to help meet indoor air quality requirements.

Discharge plenum directs the air discharge directly into

the occupiedspace;integral horizontal and vertical louvers

enable redirection of airflow. Accessory is available un-

painted or painted. Field assemblyrequired.

Standard units available from the factory are in

Double skin.

Return-air grille provides a protective barrier over the

return-air opening and givesa finished appearanceto units

installed in the occupied space. Accessoryis availableun-

painted or painted.

Subbase provides a stable, raisedplatform and room for

condensatedrain trap connection for verticalfloor-mounted

units. Accessoryis availableunpainted or painted.

Over head suspension package includes necessarybrack-

ets to support units in horizontal ceiling installations.

CO

2

sensors can be used in conjunction with the econ-

omizer accessoryto help meet indoor air quality require-

ments. The sensor signalsthe economizer to open when

the CO

2

levelin the spaceexceedsthe set point. A Carrier

Comfort Systemprogrammable thermostat can be usedto

overridethe sensorif the outsideair temperatureistoo high

or too low.

Carrier's line of ther mostats provide both program-

mable and non-programmable capability with the new

Debonair line of commercial programmable thermostats,

the TEMP System controls offer communication capabil-

ity with stagedheatingandcooling, the Commercial Elec-

tronic thermostats provide 7-day programmablecapability

for economicalapplications,while the Non-Programmable

thermostatsoffer a multitude of stagedheating and cooling

subbaseoptions.

Condensate drain trap includesan overflowshutoff switch

that can be wired to turn off the unit if the trap becomes

plugged. Kit also includesa wire harnessthat can be con-

nected to an alarm if desired. The transparent trap is de-

signedfor easyserviceand maintenance.

8

9

CARRIER THERMOSTATS

DEBONAIR COMMERCIAL PROGRAMMABLE

THERMOSTAT

AUTO

Pm

COOL

HEAT

®

TEMP SYSTEM THERMOSTAT

COMMERCIAL ELECTRONIC

THERMOSTAT

NON-PROGRAMMABLE THERMOSTAT

H

C

40RM/RMS

Options and accessories (cont)

40RM/RMS

40RM WITH DISCHARGE PLENUM,

RETURN-AIR GRILLE AND SUBBASE

DISCHARGE

PLENUM

RETURN-AIR

GRILLE

SUBBASE

FAN

COIL

UNIT

40RM WITH ECONOMIZER

ECONOMIZER

40RM WITH HOT WATER OR STEAM COIL

FAN COIL

UNIT

HOT WATER OR

STEAM COIL

40RM WITH CONDENSATE TRAP

10

Dimensions

40RM007SD-012SD

40RMS008SD-012SD

UNIT WEIGHT

UNIT

lb (kg)

40RM007SD 448 (203)

40RM008SD 452 (205)

40RM012SD 472 (214)

40RMS008SD 457 (207)

40RMS010

SD

458

(207)

40RMS012

SD 458

(207)

TXV - Thermostatic Expansion

Valve

NOTES:

1. Dimensions in [ ] are in

millimeters.

2. Direction of air¯ow.

3. Recommended clearance:

· Rear: 39(76.2mm)(28-69[762 mm]

with electric heat accessory)

· Front: 28-69(762 mm)

· Right side: 28-69(762 mm)

· Left Side: 28-69(762 mm)

· Local codes or jurisdiction may

prevail.

4. Liquid piping not supplied by

Carrier.

5. Duct flange is factory supplied and

field installed.

All the above mentioned weights

are for double skin units.

40RM/RMS

11

Dimensions (cont)

40RM014SD-024SD

40RMS014SD-024SD

40RM/RMS

UNIT

UNITWEIGHT

lb (kg)

40RM014

SD 804 (364)

40RM016

SD 819 (371)

40RM024

SD 824 (373)

40RMS014

SD

795

(360)

40RMS016

SD

811

(367)

40RMS024

SD

817 (370)

TXV - Thermostatic Expansion

Valve

NOTES:

1. Dimensions in [ ] are in

millimeters.

2. Direction of airflow.

3. Recommended clearance:

· Rear: 39 (76.2 mm) (28-69

[762 mm] with electric heat

accessory)

· Front: 28-69(762 mm)

· Right side: 28-69(762 mm)

· Left Side: 28-69(762 mm)

· Local codes or jurisdiction may

prevail.

4. Liquid piping not supplied by

Carrier.

5. Duct flange is factory supplied

and field installed.

All the weights men-

tioned in the table

are for double skin

units.

UNIT

12

40RM028SD,034SD

40RMS028SD,034SD

40RM/RMS

TXV - Thermostatic Expansion

Valve

NOTES:

1. Dimensions in [ ] are in

millimeters.

2. Direction of airflow.

3. Recommended clearance:

· Rear: 39(76.2 mm)

· Front: 28-69(762 mm)

· Right side: 28-69(762 mm)

· Left Side: 28-69(762 mm)

· Local codes or jurisdiction may

prevail.

4. Liquid piping not supplied by

Carrier.

5. Duct flange is factory supplied

and field installed.

UNIT WEIGHT

UNIT

lb (kg)

40RM028

SD 1188 (538)

40RM034

SD 1198 (542)

40RMS028

SD 1203 (544)

40RMS034

SD 1210 (548)

All the above mentioned weights are for

double skin units.

13

OVERHEAD SUSPENSION ACCESSORY

UNIT SIZES 007-012

UNIT SIZES 014-024

UNIT SIZES 028,034

NOTE: Dimensions in [ ] are millimeters.

40RM/RMS

Dimensions (cont)

14

PLENUM, RETURN-AIR GRILLE, AND SUBBASE ACCESSORIES

UNIT SIZES 007-012

UNIT SIZES 014-024

15

40RM/RMS

NOTE: Dimensions in [ ] are millimeters.

PLENUM, RETURN-AIR GRILLE, AND SUBBASE ACCESSORIES (cont)

UNIT SIZES 028,034

NOTE: Dimensions in [ ] are millimeters.

40RM/RMS

Dimensions (cont)

16

HOT WATER AND STEAM COIL ACCESSORIES

UNIT SIZES 007-012

NOTE: Dimensions in [ ] are millimeters.

DIMENSION HOT WATER COIL STEAM COIL

A 1

1

⁄

2

9 MPT [38.1] 1

1

⁄

2

9 MPT [38.1]

B 1

1

⁄

2

9 MPT [38.1] 2

1

⁄

2

9 MPT [63.5]

C 2

3

⁄

8

9 [60.3] 3

1

⁄

8

9 [79.4]

D 4

7

⁄

8

9 [123.8] 3

1

⁄

8

9 [79.4]

E 2

1

⁄

8

9 [54.0] 4

9

⁄

16

9 [115.8]

F 18-11

1

⁄

4

9 [590.6] 18-99 [584.2]

G 38-49 [1016.0] 38-49 [1016.0]

UNIT SIZES 014-024

NOTE : Dimensions in [ ] are millimeters.

DIMENSION HOT WATER COIL STEAM COIL

A 29 MPT [50.8] 1

1

⁄

2

9 MPT [38.1]

B 29 MPT [50.8] 2

1

⁄

2

9 MPT [63.5]

C 2

3

⁄

8

9 [60.3] 3

1

⁄

8

9 [79.4]

D 4

7

⁄

8

9 [123.8] 3

1

⁄

8

9 [79.4]

E 2

1

⁄

8

9 [54.0] 4

9

⁄

16

9 [115.8]

F 18-11

1

⁄

4

9 [590.6] 18-99 [584.2]

G 68-89 [2032.0] 68-89 [2032.0]

17

40RM/RMS

HOT WATER AND STEAM COIL ACCESSORIES (cont)

UNIT SIZES 028,034

DIMENSION HOT WATER COIL STEAM COIL

A 29 MPT [50.8] 1

1

⁄

2

9 MPT [38.1]

B 29 MPT [50.8] 2

1

⁄

2

9 MPT [63.5]

C 2

3

⁄

8

9 [60.3] 3

1

⁄

8

9 [79.4]

D 4

7

⁄

8

9 [123.8] 3

1

⁄

8

9 [79.4]

E 2

1

⁄

8

9 [54.0] 4

9

⁄

16

9 [115.8]

F 18-11

1

⁄

4

9 [590.6] 18-99 [584.2]

G 78-69 [2286.0] 78-69 [2286.0]

NOTE: Dimensions in [ ] are millimeters.

40RM/RMS

Dimensions (cont)

18

ECONOMIZER ACCESSORY

UNIT SIZES 007-012

UNIT SIZES 014-024

UNIT SIZES 028,034

40RM/RMS

NOTES:

1. For horizontal unit applications, economizer can be attached to end of unit opposite duct connections.

2. Dimensions in [ ] are millimeters.

19

Dimensions (cont)

ELECTRIC HEAT ACCESSORY

UNIT SIZES 007-012

40RM/RMS

UNIT SIZES 014-034

UNIT SIZE A B C D E F G H J

014-024

18-3

1

⁄

4

9

[387.4]

48-6

3

⁄

8

9

[1381.1]

2

5

⁄

16

9

[58.7]

28-1

1

⁄

4

9

[641.4]

10

5

⁄

8

9

[269.9]

18-49

[406.4]

18-4

5

⁄

16

9

[414.3]

18-6

3

⁄

4

9

[476.3]

18-

7

⁄

8

9

[327.0]

028,034

18-3

3

⁄

8

9

[390.5]

58-4

7

⁄

16

9

[1636.8]

2

1

⁄

16

9

[26.9]

28-6

3

⁄

16

9

[766.8]

18-

1

⁄

4

9

[311.2]

18-79

[482.6]

18-4

5

⁄

16

9

[414.0]

18-109

[558.8]

18-4

7

⁄

16

9

[417.1]

NOTE: Dimensions in [ ] are millimeters.

20

Selection procedure (with example)

— English (60 Hz)

Cooling (DX)

I Determine the cooling load and temperature and

quantity of air entering the evaporator.

Given:

Total Capacity ....................200,000 Btuh

Sensible Heat Capacity.............130,000 Btuh

Air Temperature Entering Indoor

Coil ........................80Fdb,67Fwb

Air Quantity Entering Indoor Coil .......6000 cfm

Ductwork Static Pressure Loss ..........0.8in.wg

Power Supply .........................230-3-60

II Determine unit selection and coil refrigerant

temperature.

Enter the Cooling Capacities table at 6000 cfm. Se-

lect a 40RM016 unit which has a total capacity of

207,000 and 174,000 Btuh at 40 and 45 F coil re-

frigerant temperature, respectively. By interpolation,

coil refrigerant temperature of 41.1 F is needed to give

a total capacity of 200,000 Btuh. Sensible capacity is

approximately 149,000 Btuh. Cooling load is

satisfied.

Heating (Hot Water Coil)

I Determine heating load and temperature of air

entering the indoor coil.

Given:

Load.............................425,000 Btuh

Entering-Air Temperature ...................70F

Coils..........................2-Row Hot Water

Coil Entering-Water Temperature ...........200F

Water Temperature Drop ...................20F

II Find the heating capacity.

Enter Hydronic Heating Capacities table for the

40RM016 unit at 6000 cfm. A 2-row hot water coil

delivers 471,000 Btuh (based on 60 F entering air

temperature and 20 F water temperature drop). Since

existing entering air temperature is 70 F, enter the

Heating Correction Factors table for hot water coils at

200 F entering water temperature, 20 F water tem-

perature drop and 70 F entering air. Read a constant

of 0.93.

471,000 x 0.93 = 438,000

The 438,000 Btuh rating satisfies the heating load.

Fan

I Determine fan speed and brake horsepower:

From the Accessory Pressure Drop table, read a loss

of 0.23 in. wg for a hot water coil at 6000 cfm.

External static pressure = 0.80 + 0.23

= 1.03 in. wg

Enter 40RM016 Fan Performance table at 6000 cfm

and 1.03 in. wg. Interpolate and determine fan speed

of 866 rpm and 2.7 bhp.

II Determine motor and drive.

Enter the fan motor data tables on page 52, and find

that the 230 v standard motor for a 40RM016 unit is

rated at 3.7 Hp. Since the bhp required is 2.7, a stand-

ard motor satisfies the requirement and should be used.

Next, find the type of drive that satisfies the 866 rpm

requirement in the Drive Data tables on pages 54-59.

For a 40RM016 unit, the Medium-Static Drive table

on page 54 shows an rpm range of 742 to 943. Since

the rpm required is 866, the medium-static drive sat-

isfies the requirement and should be used. Select the

standard motor and medium-static drive combination

(option code HC or FD).

To select an outdoor unit for this 40RM016 indoor

section, refer to the Combination Rating sheets for

Carrier condensing units in the condensing unit Prod-

uct Data Digest, or consult the Carrier Electronic

Catalog.

Cooling (Chilled Water)

NOTE: Chilled water coils (40RMS) can be selected by us-

ing Carrier’s Electronic Catalog software program.

40RM/RMS

21

Selection procedure (with example)

40RM/RMS

— SI (50 Hz)

Cooling (DX)

I Determine the cooling load and temperature and

quantity of air entering the evaporator.

Given:

Total Capacity ..........................37kW

Sensible Heat Capacity ...................29kW

Air Temp Entering

Indoor Coil .................26.7 C db, 19 C wb

Air Quantity Entering Indoor Coil .......1900 L/s

Ductwork Static Pressure Loss ............200Pa

II Determine unit selection and coil refrigerant

temperature.

Enter the Cooling Capacities table at 1900 L/s.

Select a 40RM012 unit which has a total capacity of

37.35 kW at 6 C coil refrigerant temperature. Sensible

capacity is 29.61 kW. Cooling load is satisfied.

Heating (Hot Water Coil)

I Determine heating load and temperature of air

entering the indoor coil.

Given:

Load ...................................85kW

Entering-Air Temperature ................15.6 C

Coils .........................2-Row Hot Water

Coil Entering-Water Temperature ..........93.3 C

Water Temperature Drop .................11.1 C

II Find the heating capacity.

Enter Hydronic Heating Capacities table for the

40RM012 unit at 1900 L/s. A 2-row hot water coil

delivers 90 kW (based on 15.6 C entering air tempera-

ture and 11.1 C water temperature drop).

The 90 kW rating satisfies the heating load.

Fan

I Determine fan speed and brake horsepower.

From the Accessory Pressure Drop table, read a loss

of 93 Pa for a hot water coil at 1900 L/s.

External static pressure = 200 + 93

=293Pa

Enter 40RM012 Fan Performance table at 1900 L/s

and 293 Pa. Interpolate and determine fan speed of

15.79 r/s and 1.41 kW.

II Determine motor and drive.

Enter the Fan Motor Data tables on page 52, and find

that the standard motor for a 40RM012 unit is rated

at 2.16 kW. Since the kW required is 1.41, a standard

motor satisfies the requirement and should be used.

Next, find the type of drive that satisfies the 15.79 r/s

requirement in the Drive Data tables on page 54-59.

For a 40RM012 unit, the Medium-Static Drive table

on page 59shows an r/s range of 13.5 to 17.4. Since

the r/s required is 15.79, the medium-static drive sat-

isfies the requirement and should be used. Select the

standard motor and medium-static drive combination

(option code HC or FD).

To select an outdoor unit for this 40RM012 indoor

section, refer to the Combination Rating sheets for Car-

rier condensing units in the condensing unit Product

Data Digest, or consult the latest Carrier Electronic

Catalog.

Cooling (Chilled Water)

NOTE: Select chilled water coils (40RMS) by using Carrier’s

Electronic Catalog software program.

22

Performance data

40RM COOLING CAPACITIES — ENGLISH

UNIT

40RM

EVAPORATOR

AIR

COIL REFRIGERANT TEMP (F)

Airflow

Ewb

30 35 40 45 50

(Cfm)

BF

(F)

TC SHC TC SHC TC SHC TC SHC TC SHC

72 116 55 104 50 93 46 79 40 64 35

1,800

0.06

67 96 61 85 56 74 50 61 45 47 40

62 80 66 69 61 57 55 46 46 39 39

72 135 65 121 60 108 54 92 48 75 42

007

2,400

0.10

67 112 7399 6886 6271 5655 49

62 94 81 81 75 67 67 56 56 47 47

72 150 73 135 68 120 62 102 56 83 49

3,000

0.12

67 1258511278967180656157

62 105 95 90 86 75 75 64 64 54 54

72 144 69 130 63 116 57 99 50 80 43

2,250

0.06

67 120 76 106 70 92 63 76 56 59 50

62 100 83 87 76 71 69 57 57 49 49

72 169 81 151 75 135 68 114 61 94 53

008

3,000

0.10

67 140 92 124 85 108 77 89 69 69 62

62 118 101 102 94 84 84 70 70 59 59

72 187 92 168 85 150 78 127 70 104 61

3,750

0.12

67 157 106 140 97 120 89 100 81 77 72

62 132 118 112 108 94 94 80 80 68 68

72 193 92 174 81 154 76 132 67 108 58

3,000

0.05

67 161 102 143 93 123 85 102 76 79 67

62 134 111 116 102 96 93 78 78 66 66

72 223 108 201 99 179 91 153 81 125 71

012

4,000

0.07

67 186 122 166 113 143 104 119 93 92 82

62 157 136 136 126 113 113 95 95 80 80

72 246 122 222 112 198 103 169 93 138 81

5,000

0.12

67 207 140 185 131 159 120 132 109 102 97

62 175 159 149 145 126 126 109 109 92 92

72 223 107 204 99 183 91 157 81 127 70

3,750

0.06

67 188 121 169 112 144 102 118 90 94 81

62 154 133 136 123 114 111 94 94 80 80

72 259 126 234 117 210 108 180 97 145 85

014

5,000

0.08

67 220 146 194 136 166 124 138 112 110 100

62 178

163 156 150 134 134 114 114 97 97

72 284 142 257 132 230 122 198 111 160 98

6,250

0.10

67 242 166 209 154 183 145 153 131 119 117

62 197 188 172 172 150 150 130 130 111 111

72 282 134 254 123 228 112 194 100 162 89

4,500

0.03

67 233 149 209 138 178 125 149 112 117 99

62 192 163 169 151 141 138 116 116 98 98

72 320 156 293 145 263 134 223 119 179 104

016

6,000

0.05

67 276 181 243 167 207 153 174 137 137 123

62 225 200 198 185 167 167 140 140 119 119

72 358 177 319 163 290 152 248 137 197 120

7,500

0.08

67 305 208 263 192 229 178 193 160 153 144

62 251 232 218 215 188 188 161 161 136 136

72 365 174 330 161 296 147 254 131 206 114

6,000

0.03

67 309 198 274 182 234 166 195 150 153 132

62 250 216 221 200 186 182 155 155 132 132

72 416 203 378 189 338 174 291 157 235 138

024

8,000

0.06

67 354 237 305 217 269 202 224 183 179 163

62 290 264 253 245 218 218 187 187 159 159

10,000

0.07

72 454 228 413 213 373 198 319 179 259 160

67 376 266 338 251 296 235 250 214 194 189

62 316 303 279 278 244 244 213 213 182 182

40RM/RMS

23

Performance data (cont)

40RM COOLING CAPACITIES — ENGLISH (cont)

40RM/RMS

UNIT

40RM

EVAPORATOR

AIR

COIL REFRIGERANT TEMP (F)

Airflow

Ewb

30 35 40 45 50

(Cfm)

BF

(F)

TC SHC TC SHC TC SHC TC SHC TC SHC

72 440 211 394 193 361 180 312 162 255 142

7,500

0.04

67 374 241 385 225 287 205 235 184 191 166

62 303 265 270 247 229 226 193 193 165 165

72 498 246 454 229 408 212 354 193 288 170

028

10,000

0.06

67 425 288 373 267 327 249 271 226 220 203

62 350 325 306 302 267 267 232 232 199 199

72 — — 495 258 445 240 385 220 318 198

12,500

0.08

67 456 327 408 308 359 289 304 265 239 235

62 380 375 336 336 299 299 264 264 226 226

72 527 253 473 232 433 216 375 194 306 170

9,000

0.04

67 449 290 402 270 345 246 282 221 229 199

62 364 318 323 297 275 271 232 232 198 198

72 598 295 545 275 490 254 425 232 346 205

034

12,000

0.06

67 510 346 448 321 393 298 326 271 263 244

62 420 390 367 362 321 321 279 279 238 238

15,000

0.08

72 — — 594 309 534 288 462 264 382 237

67 547 392 490 370 431 347 365 318 287 282

62 456 450 403 403 359 359 317 317 271 271

LEGEND

BF — Bypass Factor

db — Dry-Bulb Temp (F)

Ewb — Entering Wet-Bulb Temp (F)

lwb — Leaving Wet-Bulb Temp (F)

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh)

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. Evaporator fan heat not deducted from ratings.

3. Ratings based on approximately 15 F superheat leaving coil.

4. Dashes indicate coil loading limits are exceeded.

5. Formulas:

Leaving db = entering db −

sensible heat capacity (Btuh)

1.1 x cfm

Leaving wb = wet-bulb temperature corresponding to enthalpy of

air leaving coil (h

lwb

)

h

lwb

=h

ewb

−

total capacity (Btuh)

4.5 x cfm

where h

ewb

=

enthalpy of air entering coil

6. SHC is based on 80 F db temperature of air entering evaporator coil.

Below 80 F db, subtract (corr factor x cfm) from SHC.

Above 80 F db, add (corr factor x cfm) to SHC. See italic type

below.

BYPASS

ENTERING AIR DRY-BULB TEMP (F)

79 78 77 76 75 Under 75

FACTOR

81 82 83 84 85 Over 85

Correction Factor

0.02

0.05

0.10

0.15

0.20

0.25

0.30

1.08

1.05

0.99

0.94

0.88

0.83

0.77

2.16

2.09

1.98

1.87

1.76

1.65

1.54

3.23

3.14

2.97

2.81

2.64

2.48

2.31

4.31

4.18

3.96

3.74

3.52

3.30

3.08

5.39

5.23

4.95

4.68

4.40

4.13

3.85

use formula

shown below

Interpolation is permissible.

Correction Factor = 1.1 x (1 − BF) x (db − 80)

24

40RM COOLING CAPACITIES — SI

UNIT

40RM

EVAPORATOR

AIR

COIL REFRIGERANT TEMP (C)

Airflow

Ewb

−1 0 2 4 6 8 10

(L/s)

BF

(C)

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

22 33.73 16.27 32.43 15.75 29.83 14.69 27.23 13.64 24.62 12.60 22.02 11.57 19.40 10.57

850

.06

19 27.79 18.51 26.56 17.93 24.10 16.78 21.64 15.63 19.17 14.51 16.70 13.41 14.22 12.41

16 22.73 21.09 21.58 20.29 19.27 18.70 16.95 16.95 14.62 14.62 12.28 12.28 9.93 9.93

22 39.24 19.50 37.73 18.87 34.70 17.60 31.68 16.34 28.66 15.09 25.63 13.89 22.60 12.66

007

1150

.10

19 32.37 22.21 30.93 21.58 28.06 20.32 25.18 19.08 22.30 17.86 19.41 16.79 16.51 15.64

16 26.41 25.86 25.15 24.85 22.64 22.64 20.11 20.11 17.58 17.58 15.04 15.04 12.49 12.49

22 43.88 21.85 42.16 21.22 38.71 19.97 35.26 18.72 31.82 17.50 28.37 16.33 24.92 23.63

1450

.12

19 36.69 25.31 35.04 24.63 31.74 23.30 28.44 21.99 25.14 20.73 21.83 19.63 18.52 18.52

16 29.14 29.14 27.82 27.82 25.19 25.19 22.55 22.55 19.91 19.91 17.26 17.26 14.61 14.61

22 42.12 20.58 40.51 19.89 37.29 18.52 34.07 17.16 30.84 15.80 27.61 14.46 24.37 13.18

1000

.06

19 34.64 23.22 33.11 22.48 30.05 21.01 26.97 19.55 23.89 18.12 20.80 16.74 17.71 15.49

16 28.76 26.41 27.26 25.39 24.26 23.38 21.25 21.25 18.22 18.22 15.17 15.17 12.10 12.10

22 49.07 24.22 47.14 23.49 43.29 22.02 39.43 20.56 35.57 19.12 31.71 17.72 27.85 16.48

008

1400

.10

19 40.52 27.88 38.72 27.04 35.13 25.38 31.54 23.74 27.94 22.15 24.33 20.67 20.71 19.62

16 33.30 32.38 31.70 31.12 28.48 28.48 25.25 25.25 22.01 22.01 18.76 18.76 15.50 15.50

22 54.60 27.31 52.46 26.52 48.17 24.95 43.89 23.40 39.61 21.87 35.32 20.41 31.04 19.32

1800

.12

19 45.87 31.43 43.80 30.60 39.68 28.96 35.55 27.35 31.42 25.81 27.28 24.47 23.14 23.14

16 36.21 36.21 34.59 34.59 31.35 31.35 28.10 28.10 24.85 24.85 21.59 21.59 18.33 18.33

22 56.46 26.00 54.28 25.26 49.91 23.80 45.53 22.33 41.15 20.89 36.77 19.47 32.38 18.13

1450

.05

19 46.83 30.42 44.73 29.53 40.53 27.76 36.32 26.01 32.10 24.29 27.87 22.64 23.64 21.21

16 38.11 34.82 36.21 33.56 32.39 31.04 28.56 28.55 24.71 24.71 20.85 20.85 16.97 16.97

22 65.14 31.89 62.64 30.94 57.64 29.05 52.64 27.17 47.63 25.30 42.62 23.47 37.61 21.73

012

1900

.07

19 54.26 36.83 51.85 35.78 47.03 33.70 42.19 31.64 37.35 29.61 32.51 27.68 27.65 26.01

16 44.18 43.13 42.12 41.49 37.99 37.99 33.85 33.85 29.71 29.71 25.55 25.55 21.37 21.37

22 71.98 35.85 69.21 34.85 63.67 32.86 58.13 30.89 52.59 28.93 47.05 27.03 41.51 25.31

2350

.12

19 60.62 42.44 57.89 41.30 52.41 39.02 46.93 36.77 41.45 34.59 35.97 32.55 30.49 30.49

16 47.82 47.82 45.79 45.79 41.72 41.72 37.66 37.66 33.59 33.59 29.52 29.52 25.44 25.44

22 65.89 31.93 63.44 30.98 58.55 29.09 53.65 27.21 48.75 25.34 43.85 23.49 38.94 21.73

1750

.06

19 55.70 36.93 53.09 35.77 47.85 33.46 42.61 31.18 37.35 28.93 32.09 26.75 26.81 24.76

16 44.35 42.14 42.24 40.60 38.02 37.55 33.78 33.78 29.53 29.53 25.27 25.27 20.98 20.98

22 75.61 37.49 72.79 36.44 67.15 34.34 61.51 32.26 55.87 30.19 50.23 28.16 44.58 26.26

014

2350

.08

19 63.64 44.28 60.75 43.02 54.97 40.53 49.19 38.06 43.40 35.64 37.61 33.33 31.81 31.36

16 50.09

50.09 47.97 47.97 43.71 43.71 39.44 39.44 35.17 35.17 30.90 30.90 26.62 26.62

22 83.01 42.04 79.93 40.94 73.75 38.75 67.58 36.57 61.41 34.42 55.23 32.34 49.06 30.52

2950

.10

19 67.98 49.45 65.08 48.26 59.28 45.89 53.48 43.57 47.68 41.33 41.88 39.29 36.08 36.08

16 54.67 54.67 52.53 52.53 48.24 48.24 43.96 43.96 39.67 39.67 35.38 35.38 31.10 31.10

22 82.25 39.79 79.12 38.58 72.88 36.16 66.62 33.74 60.37 31.34 54.10 28.97 47.84 26.65

2100

.03

16 68.47 45.43 65.39 44.06 59.24 41.32 53.07 38.61 46.89 35.94 40.70 33.33 34.50 30.88

16 55.23 51.82 52.57 49.96 47.23 46.25 41.88 41.88 36.52 36.52 31.13 31.13 25.73 25.73

22 94.97 46.65 91.32 45.28 84.03 42.55 76.72 39.83 69.42 37.13 62.11 34.48 54.80 31.95

016

2800

.05

19 79.48 54.48 75.93 52.91 68.84 49.78 61.73 46.68 54.62 43.64 47.50 40.72 40.37 38.14

16 64.12 63.23 61.19 60.85 55.34 55.34 49.48 49.48 43.61 43.61 37.72 37.72 31.82 31.82

22 102.66 51.90 98.96 50.54 91.55 47.82 84.14 45.12 76.73 42.46 69.32 39.90 61.90 37.72

3500

.08

19 85.35 62.06 81.75 60.40 74.54 57.09 67.33 53.84 60.11 50.69 52.89 47.79 45.66 45.66

16 69.63 69.63 66.75 66.75 60.99 60.99 55.23 55.23 49.45 49.45 43.67 43.67 37.88 37.88

22 106.58 52.05 102.62 50.46 94.70 47.29 86.78 44.13 78.85 40.98 70.92 37.84 62.99 34.74

2900

.03

19 89.80 59.51 85.74 57.82 77.63 54.44 69.50 51.08 61.37 47.75 53.21 44.47 45.05 41.29

16 71.75 68.29 68.44 65.88 61.79 61.08 55.13 55.13 48.45 48.45 41.75 41.75 35.03 35.03

22 122.11 60.50 117.57 58.81 108.48 55.45 99.38 52.11 90.29 48.79 81.19 45.52 72.10 42.39

024

3800

.06

19 99.07 69.97 94.89 68.20 86.53 64.66 78.16 61.17 69.79 57.74 61.41 54.46 53.03 51.58

16 80.95 80.95 77.60 77.60 70.90 70.90 64.19 64.19 57.48 57.48 50.76 50.76 44.03 44.03

4700

.07

22 133.27 67.86 128.35 66.08 118.51 62.52 108.68 58.97 98.84 55.46 89.00 52.01 79.16 48.77

19 109.55 80.54 104.99 78.62 95.88 74.79 86.76 71.01 77.65 67.33 68.53 63.85 59.41 59.41

16 88.34 88.34 84.97 84.97 78.24 78.24 71.50 71.50 64.76 64.76 58.02 58.02 51.28 51.28

40RM/RMS

25

Performance data (cont)

40RM COOLING CAPACITIES — SI (cont)

40RM/RMS

UNIT

40RM

EVAPORATOR

AIR

COIL REFRIGERANT TEMP (C)

Airflow

Ewb

−1 0 2 4 6 8 10

(L/s)

BF

(C)

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

22 125.95 61.58 121.69 59.95 113.17 56.69 104.65 53.45 96.11 50.22 87.57 47.04 79.02 43.94

3500

.04

19 131.38 73.49 123.70 71.33 108.30 67.03 92.87 62.76 77.40 58.55 61.89 54.43 46.34 46.34

16 86.95 83.51 83.12 80.66 75.43 74.98 67.71 67.71 59.95 59.95 52.17 52.17 44.34 44.34

22 146.03 72.86 140.80 70.97 130.35 67.19 119.89 63.44 109.43 59.71 98.98 56.05 88.52 52.56

028

4700

.06

19 121.55 85.85 116.28 83.71 105.73 79.45 95.19 75.24 84.63 71.12 74.08 67.17 63.52 63.52

16 97.09 97.09 93.33 93.33 85.80 85.80 78.27 78.27 70.74 70.74 63.20 63.20 55.66 55.66

22 159.37 81.76 153.60 79.77 142.08 75.79 130.55 71.82 119.02 67.89 107.49 64.01 95.96 60.28

5900

.08

19 131.94 98.52 126.54 96.29 115.74 91.83 104.94 87.43 94.14 83.12 83.34 78.97 72.54 72.54

16 105.39 105.39 101.70 101.70 94.30 94.30 86.91 86.91 79.52 79.52 72.13 72.13 64.73 64.73

22 151.16 74.13 146.07 72.13 135.88 68.13 125.69 64.15 115.49 60.19 105.27 56.27 95.05 52.43

4250

.04

19 132.16 88.16 126.02 85.58 113.73 80.44 101.41 75.33 89.07 70.27 76.70 65.32 64.29 60.59

16 103.92 100.45 99.38 97.00 90.28 90.14 81.14 81.14 71.97 71.97 62.77 62.77 53.52 53.52

22 175.30 87.47 169.02 85.21 156.48 80.70 143.93 76.21 131.38 71.76 118.83 67.38 106.28 63.19

034

5650

.06

19 145.93 103.33 139.63 100.72 127.01 95.52 114.39 90.38 101.76 85.34 89.14 80.49 76.50 76.18

16 116.36 116.36 111.88 111.88 102.92 102.92 93.96 93.96 85.00 85.00 76.03 76.03 67.06 67.06

7050

.08

22 191.24 97.85 184.33 95.48 170.49 90.77 156.66 86.08 142.82 81.42 128.99 76.84 115.15 72.42

19 158.48 118.39 151.99 115.68 139.01 110.30 126.02 104.97 113.04 99.75 100.05 94.74 87.07 87.07

16 126.37 126.37 121.95 121.95 113.12 113.12 104.29 104.29 95.45 95.45 86.62 86.62 77.78 77.78

LEGEND

BF — Bypass Factor

Edb — Entering Dry Bulb

Ewb — Entering Wet Bulb

Ldb — Leaving Dry Bulb

Lwb — Leaving Wet Bulb

SHC — Sensible Heating Capacity (kW)

TC — Total Capacity (kW)

NOTES:

1. Ratings based on approximately 8.3 C superheat leaving coil.

2. Direct interpolation is permissible. Do not extrapolate.

3. The SHC is based on 26.7 C db temperature of air entering the unit.

At any other temperature, correct the SHC reading from the table of

cooling capacities as follows:

Correction factor = 1.23 x 10

−3

x (1 −BF) x (db −26.7)

Above 26.7 C, add SHC correction to SHC. Below 26.7 C, subtract

SHC correction from SHC.

4. Gross capacities shown do not include a deduction for evaporator-

fan motor heat.

5. Formulas (cooling):

t

ldb

=t

edb

−

sensible heat capacity (kW)

1.23 x 10

-3

x (L/s)

t

lwb

= wet-bulb temperature corresponding to enthalpy of air leav-

ing coil (h

lwb

)

total capacity (kW)

h

lwb

=h

ewb

−

1.20 x 10

−3

x (L/s)

where h

ewb

= enthalpy of air entering coil (kJ/kg)

26

HYDRONIC HEATING CAPACITIES — ENGLISH HYDRONIC HEATING CAPACITIES — SI

1-ROW 2-ROW

UNIT

AIRFLOW

(Cfm)

STEAM* HOT WATER COIL†

Cap. Ldb Cap. Ldb

Water

Flow

(Gpm)

PD

40RM

007

1,800

2,400

3,000

146

173

209

134

126

123

156.0

183.0

206.0

140

131

124

15.6

18.3

20.6

3.4

4.3

5.2

40RM

40RMS

008

2,250

3,000

3,750

168

209

240

129

123

117

174.0

206.0

238.0

133

124

118

17.4

20.6

23.8

4.0

5.2

6.5

40RMS

010

2,550

3,400

4,250

183

229

254

125

121

114

199.0

233.0

271.0

132

123

119

19.9

23.3

27.1

4.5

5.7

7.2

40RM

40RMS

012

3,000

4,000

5,000

209

243

279

123

115

111

299.0

275.0

316.0

152

124

119

29.9

27.5

31.6

5.0

6.6

8.2

40RM

40RMS

014

3,750

5,000

6,250

370

425

465

150

137

128

362.0

409.0

456.0

149

136

128

36.2

40.9

45.6

4.2

5.1

6.0

40RM

40RMS

016

4,500

6,000

7,500

402

458

479

141

129

11

8

412.0

471.0

529.0

145

133

125

41.2

47.1

52.9

4.5

5.5

6.6

40RM

40RMS

024

6,000

8,000

10,000

458

487

499

129

115

105

506.0

584.0

652.0

138

128

120

50.6

58.4

65.2

5.1

6.3

7.5

40RM

40RMS

028

7,500

10,000

12,500

511

575

626

122

112

106

649.0

752.0

842.0

140

130

122

64.9

75.2

84.2

5.7

7.1

8.5

40RM

40RMS

034

9,000

12,000

15,000

560

621

670

117

107

101

735.0

850.0

950.0

136

126

119

73.5

85.0

95.0

6.2

7.8

9.3

1-ROW 2-ROW

UNIT

AIRFLOW

(L/s)

STEAM* HOT WATER COIL†

Cap. Ldb Cap. Ldb

Water

Flow

(L/s)

PD

40RM

007

850

1150

1450

43

53

62

57

53

51

46

53

61

59

53

50

1.0

1.2

1.3

10.2

12.8

16.0

40RM

40RMS

008

1000

1400

1800

48

59

71

55

50

47

50

60

70

56

50

47

1.1

1.3

1.5

1

1.5

15.3

19.5

40RMS

010

1200

1600

2000

54

64

74

52

48

46

58

69

79

55

50

48

1.3

1.5

1.7

13.4

17.3

21.4

40RM

40RMS

012

1450

1900

2350

62

72

82

50

46

44

88

90

93

65

54

48

1.9

2.0

2.0

15.0

24.7

24.5

40RM 1750 108 66 106 65 2.3 12.4

40RMS 2350 122 58 120 57 2.6 15.2

014 2950 136 53 134 52 2.9 17.9

40RM

40RMS

016

2100

2800

3500

117

129

140

61

53

48

120

137

154

62

55

51

2.6

3.0

3.3

13.3

16.2

19.5

40RM 2900 135 53 150 58 3.3 15.6

40RMS 3800 140 46 170 52 3.7 18.6

024 4700 146 41 191 49 4.1 22.3

40RM 3500 149 50 189 60 4.1 16.9

40RMS 4700 166 44 218 53 4.7 20.8

028 5900 183 41 247 50 5.4 25.4

40RM 4250 164 47 215 57 4.7 18.5

40RMS 5650 180 41 247 51 5.4 22.8

034 7050 196 38 278 48 6.0 27.7

40RM/RMS

LEGEND

Cap. — Capacity (Btuh in thousands)

Ldb — Leaving-Air Dry-Bulb Temp (F)

PD — Pressure Drop (ft water)

*Based on 5 psig steam, 60 F entering-air temperature. All steam coils are non-

freeze type.

†Based on 200 F entering water, 20 F water temperature drop, 60 F entering-air

temperature.

NOTES:

1. Maximum operating limits for heating coils: 175 psig at 400 F.

Capacity (Btuh)

2. Leaving db = ent db (F) +

1.1 x cfm

3. See Heating Correction Factors table.

HEATING CORRECTION FACTORS − ENGLISH

HOT WATER COIL

LEGEND

Cap. — Capacity (kW)

Ldb — Leaving-Air Dry-Bulb Temp (C)

PD — Pressure Drop (kPa)

*Based on 34.5 kPag steam, 15.6 C entering-air temperature. All steam coils are

non-freeze type.

†Based on 93.3 C entering-water temperature, 11.1 C water temperature drop,

15.6 C entering-air temperature.

NOTES:

1. Maximum operating limits for heating coils: 1207 kPag at 204.4 C.

Capacity (kW)

2. Leaving db = ent db (C) +

1.23 x 10

-3

x L/s

3. See Heating Correction Factors table.

HEATING CORRECTION FACTORS — SI

HOT WATER COIL

Water Temp

Drop

(F)

Ent Water

Temp

(F)

Entering-Air Temp (F)

40 50 60 70 80

10

140

160

180

200

220

0.72

0.89

1.06

1.22

1.39

0.64

0.81

0.98

1.15

1.32

0.57

0.74

0.90

1.07

1.24

0.49

0.66

0.83

1.00

1.17

0.41

0.58

0.75

0.92

1.09

20

140

160

180

200

220

0.64

0.81

0.98

1.15

1.32

0.57

0.74

0.91

1.08

1.25

0.49

0.66

0.83

1.00

1.17

0.41

0.58

0.75

0.93

1.10

0.33

0.51

0.68

0.85

1.02

30

140

160

180

200

220

0.56

0.74

0.91

1.08

1.25

0.49

0.66

0.83

1.00

1.18

0.41

0.58

0.76

0.93

1.10

0.33

0.51

0.68

0.85

1.03

0.24

0.43

0.60

0.78

0.95

W

ater Temp

Drop

(C)

Ent Water

Temp

(C)

Entering-Air Temp (C)

4 10162025

5

60

70

80

90

100

0.72

0.87

1.02

1.17

1.32

0.64

0.79

0.94

1.09

1.24

0.55

0.71

0.86

1.01

1.16

0.50

0.65

0.80

0.95

1.10

0.43

0.58

0.73

0.89

1.04

11

60

70

80

90

100

0.65

0.80

0.95

1.10

1.26

0.56

0.72

0.87

1.02

1.18

0.48

0.63

0.79

0.94

1.09

0.42

0.58

0.73

0.89

1.04

0.35

0.51

0.66

0.82

0.97

16

60

70

80

90

100

0.56

0.72

0.87

1.02

1.18

0.48

0.63

0.79

0.94

1.10

0.39

0.55

0.70

0.86

1.02

0.33

0.49

0.65

0.81

0.97

0.26

0.42

0.58

0.74

0.90

STEAM COIL

STEAM COIL

Steam Pressure

(psig)

Entering-Air Temp (F)

40 50 60 70 80

0

2

5

1.06

1.09

1.13

0.98

1.02

1.06

0.91

0.95

1.00

0.85

0.89

0.93

0.78

0.82

0.87

Steam

Pressure

(kPag)

Entering-Air Temp (C)

4 10162025

0

14

35

1.07

1.10

1.14

0.99

1.02

1.07

0.91

0.95

0.99

0.86

0.90

0.95

0.80

0.84

0.89

NOTE: Multiply capacity given in the Hydronic Heating Capacities table by the

NOTE: Multiply capacity given in the Hydronic Heating Capacities table by the

correction factor for conditions at which unit is actually operating. Correct leaving-

correction factor for conditions at which unit is actually operating. Correct leaving-

air temperature using formula in Note 2 of Hydronic Heating Capacities table.

air temperature using formula in Note 2 of Hydronic Heating Capacities table.

27

Performance data (cont)

FAN PERFORMANCE DATA — 0.0-1.2 in. wg ESP — 60 Hz, ENGLISH

40RM/RMS

UNIT

AIRFLOW

(Cfm)

EXTERNAL STATIC PRESSURE (in. wg)

0.0 0.2 0.4 0.6 0.8 1.0 1.2

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

40RM

007

1,800

2,100

2,400

2,700

3,000

320

373

427

480

533

0.22

0.31

0.42

0.54

0.69

442

483

526

570

616

0.32

0.42

0.53

0.67

0.82

534

569

606

646

687

0.42

0.53

0.64

0.78

0.94

611

642

676

712

750

0.52

0.63

0.75

0.89

1.05

678

708

739

773

808

0.61

0.73

0.86

1.00

1.16

739

767

796

828

862

0.70

0.82

0.96

1.11

1.28

795

821

849

880

912

0.80

0.92

1.06

1.21

1.39

40RM

40RMS

008

2,250

2,600

3,000

3,400

3,750

359

415

478

542

598

0.32

0.45

0.62

0.82

1.03

472

516

569

624

673

0.44

0.57

0.75

0.95

1.17

560

599

645

695

740

0.55

0.68

0.86

1.08

1.29

634

669

712

758

800

0.65

0.79

0.98

1.20

1.42

700

732

773

815

855

0.75

0.90

1.09

1.31

1.60

759

790

828

869

906

0.86

1.01

1.20

1.43

1.66

814

843

879

918

954

0.96

1.11

1.32

1.55

1.78

40RMS

010

2,550

2,975

3,400

3,825

4,250

396

462

527

593

659

0.42

0.60

0.80

1.05

1.33

502

556

612

670

729

0.54

0.72

0.93

1.18

1.47

586

634

684

737

791

0.65

0.84

1.06

1.31

1.60

658

701

748

797

848

0.76

0.95

1.18

1.44

1.73

722

762

806

852

901

0.87

1.06

1.30

1.56

1.86

780

818

860

904

950

0.97

1.18

1.41

1.68

1.98

833

870

910

952

997

1.08

1.29

1.53

1.80

2.11

40RM

40RMS

012

3,000

3,500

4,000

4,500

5,000

444

518

592

666

740

0.58

0.82

1.11

1.44

1.83

541

604

669

735

803

0.71

0.95

1.25

1.59

1.98

621

677

736

797

861

0.83

1.08

1.38

1.72

2.12

691

742

797

854

914

0.94

1.20

1.51

1.86

2.26

753

801

853

907

964

1.05

1.32

1.63

1.99

2.39

809

855

904

956

1010

1.17

1.44

1.75

2.12

2.53

862

906

953

1003

1055

1.28

1.56

1.88

2.24

2.66

40RM

40RMS

014

3,750

4,300

5,000

5,700

6,250

363

416

484

552

605

0.37

0.53

0.81

1.17

1.51

475

517

573

631

678

0.58

0.78

1.08

1.47

1.83

566

601

650

702

744

0.80

1.02

1.35

1.76

2.15

645

676

719

766

805

1.02

1.26

1.62

2.06

2.47

715

743

782

826

862

1.24

1.50

1.89

2.36

2.79

779

805

841

881

915

1.47

1.74

2.16

2.66

3.11

839

862

896

934

966

1.69

1.99

2.44

2.96

3.43

40RM

40RMS

016

4,500

5,300

6,000

6,800

7,500

391

460

521

590

651

0.51

0.80

1.13

1.60

2.10

495

551

602

663

718

0.75

1.08

1.43

1.93

2.45

581

629

675

730

779

1.00

1.35

1.73

2.26

2.81

657

700

741

791

837

1.25

1.63

2.04

2.59

3.16

725

764

801

847

890

1.50

1.91

2.34

2.92

3.52

787

823

858

901

941

1.76

2.20

2.65

3.26

3.88

845

878

911

951

990

2.02

2.48

2.96

3.60

4.24

40RM

40RMS

024

6,000

7,000

8,000

9,000

10,000

503

586

670

754

838

1.07

1.64

2.37

3.28

4.39

587

660

735

812

891

1.37

1.98

2.74

3.69

4.83

661

726

795

867

941

1.67

2.31

3.12

4.09

5.27

727

787

851

918

988

1.97

2.65

3.49

4.50

5.70

789

844

904

967

1034

2.28

2.99

3.86

4.90

6.14

846

898

954

1014

1077

2.59

3.33

4.23

5.31

6.85

900

948

1001

1059

1120

2.90

3.67

4.61

5.72

7.02

40RM

40RMS

028

7,500

8,750

10,000

11,250

12,500

412

481

549

618

687

1.15

1.76

2.55

3.52

4.71

492

550

610

672

735

1.53

2.17

2.99

4.00

5.22

568

616

669

725

783

2.00

2.66

3.50

4.53

5.78

640

680

726

777

830

2.56

3.22

4.07

5.12

6.38

710

742

782

827

876

3.22

3.86

4.70

5.76

7.04

776

802

836

876

922

3.98

4.58

5.40

6.45

7.74

840

860

889

925

966

4.83

5.38

6.17

7.21

8.49

40RM

40RMS

034

9,000

10,500

12,000

13,500

15,000

471

550

628

707

785

1.78

2.72

3.93

5.44

7.27

539

608

679

752

826

2.17

3.15

4.40

5.94

7.81

604

665

730

797

867

2.63

3.64

4.92

6.49

8.39

667

720

779

841

907

3.17

4.18

5.48

7.08

9.01

728

774

827

885

947

3.78

4.79

6.09

7.71

9.66

788

827

874

928

986

4.46

5.45

6.76

8.38

10.35

845

878

921

970

1024

5.22

6.18

7.47

9.10

11.07

See Legend and Notes on page 32.

28

FAN PERFORMANCE DATA — 1.4-2.4 in. wg ESP — 60 Hz, ENGLISH

UNIT

AIRFLOW

(Cfm)

1.4

Rpm Bhp

1.6

Rpm Bhp

EXTERNAL STATIC PRESSURE (in. wg)

1.8 2.0 2.2

Rpm Bhp Rpm Bhp Rpm Bhp

2.4

Rpm Bhp

1,800 847 0.89 896 0.98 942 1.07 986 1.16 1027 1.25 — —

40RM

007

2,100

2,400

2,700

872

899

928

1.02

1.16

1.32

920

946

974

1.11

1.26

1.42

965

990

1018

1.21

1.36

1.52

1008

1033

1059

1.30

1.46

1.63

1050

1073

1099

1.40

1.55

1.73

—

—

—

—

—

—

3,000 959 1.49 1004 1.60 1046 1.71

1087 1.81 1126 1.92

——

40RM

40RMS

008

2,250

2,600

3,000

3,400

865

893

928

965

1.06

1.22

1.43

1.66

913

940

973

1010

1.16

1.33

1.54

1.78

958

984

1017

1052

1.27

1.43

1.65

1.89

1001

1027

1058

1092

1.37

1.54

1.76

2.00

1042

1067

1098

1131

1.47

1.65

1.87

2.12

—

—

—

—

—

—

—

—

3,750 1000 1.90 1043 2.02 1084 2.13 1124 2.25 1162 2.37 — —

2,550 884 1.18 931 1.29 975 1.40 1018 1.50 1059 1.61 — —

40RMS

010

2,975

3,400

3,825

919

957

998

1.40

1.64

1.92

965

1002

1041

1.51

1.76

2.04

1009

1044

1082

1.62

1.87

2.16

1050

1085

1122

—

1.73

1.98

2.27

—

1090

1124

1160

—

1.84

2.10

2.39

—

—

—

—

—

—

—

—

—

4,250 1041 2.23

1083 2.35 1123 2.48 1161 2.60 1199 2.72 — —

3,000 911 1.39 958 1.50 1002 1.61 1044 1.72 1084 1.83 1123 1.94

40RM

40RMS

012

3,500

4,000

4,500

953

999

1047

1.67

2.00

2.37

998

1042

1089

1.79

2.12

2.50

1041

1084

1129

1.90

2.24

2.62

1082

1124

1168

2.02

2.36

2.74

1122

1162

—

2.13

2.48

—

1159

1199

—

2.25

2.60

—

5,000 1097 2.79 1138 2.92 1177 3.05

——————

3,750 894 1.91 947 2.14 996 2.37 1044 2.60 1089 2.83 — —

40RM

40RMS

014

4,300

5,000

5,700

916

948

984

2.23

2.71

3.25

967

997

1031

2.48

2.98

3.55

1016

1044

1076

2.73

3.26

3.86

1062

1089

1120

2.98

3.53

4.16

1107

1133

1162

—

3.24

3.81

4.46

—

—

—

—

—

—

—

—

—

6,250 1014 3.75 1060 4.07 1104 4.39 1147 4.71 1188 5.03 — —

4,500 899 2.29 951 2.56 999 2.84 1046 3.12 1091 3.41 1133 3.70

40RM

40RMS

016

5,300

6,000

6,800

930

961

999

2.78

3.28

3.94

980

1009

1045

3.08

3.60

4.28

1027

1055

1089

3.38

3.92

4.63

1072

1098

1132

3.68

4.24

4.98

1116

1141

1173

3.99

4.57

5.33

1157

1181

—

4.30

4.91

—

7,500 1036 4.60 1080 4.97 1123 5.34 1164 5.71

————

6,000 950 3.21 999 3.53 1045 3.85 1089 4.17 1131 4.50 1172 4.83

40RM

40RMS

024

7,000

8,000

9,000

996

1047

1102

4.02

4.99

6.13

1042

1091

1143

4.37

5.37

6.54

1086

1133

1183

4.72

5.75

6.96

1129

1173

—

5.07

6.13

—

1169

—

—

5.43

—

—

—

—

—

—

—

—

10,000 1160 7.46 1200 7.91 — — — — — — — —

7,500 903 5.79 963 6.83 1021 7.98 1078 9.21 — — — —

40RM

40RMS

028

8,750

10,000

1

1,250

917

941

972

6.26

7.01

8.02

972

991

1019

7.22

7.91

8.89

1025

1040

1064

8.26

8.89

9.83

1078

1089

—

9.38