HeaterKit

BM23608

INSTALLATIONINSTRUCTIONS

HeaterKit

M17235814APR20(ENGLISH)

HPX,HPX615E,HPX815E,XUV620i,XUV625i,XUV825E,

XUV825i,XUV825iS4,XUV825M,XUV825MS4,

XUV855D,XUV855DS4,XUV855E,XUV855M,XUV855M

S4Gator™UtilityVehicles

JohnDeereHoriconWorks

M172358(14APR20)

PRINTEDINU.S.A.

COPYRIGHT©2020

DEERE&COMPANY

Moline,Illinois

Allrightsreserved.

AJohnDeereILLUSTRUCTION™Manual

PreviousEditions

Copyright©2013,2016,2018

M172358-19-14APR20

BM23608

OUMX068,00003FD-19-22JAN13-1/1

BVVMSIT,000021A-19-25MAR20-1/1

FENAFNX,0000155-19-13APR20-1/1

Grease

NOTE:Asuitabledielectricgreasemustbeapplied

wheninstallingthiskit.YoucanpurchaseMPG2

greasefromyourlocalJohnDeeredealer.

PartsinKit

HeaterKit

QuantityDescription

1

T-tting(A)

1

BleederT-tting(B)

1

Heater/BlowerUnit

1

PaddedHeaterCover

1

FloorCover(withhardware)

1

HeaterRetainingPanel(withhardwareand

electricalharnesses)

2

Grommet

2

HoseClamp,1-1/2inch

4

HoseClamp,1inch

1HoseBracket

2HoseProtector

1

ShortExtensionHeaterHoseSection

1PopRivet

8Washer,M8

2Washer,M6

2Locknut,M6

1

Self-threadingScrew

4HexHeadBolt,M6x16

3HexHeadBolt,M6x20

12

TieStrap

NOTE:Retaintheseinstallationinstructionswiththe

machineoperator’smanual.

MXT014968—UN—07JUL15

A—T-ttingB—BleederT-tting

NOTE:Somepartsmaynotbeuseddepending

uponyourmachinemodel.

AdditionalFittingKitPartsRequiredfor

Installation

Thettingsusedtoconnecttheheaterhosestothe

enginearenotthesameforthethreetypesofengines.

Oneofthreefollowingkitsisrequiredtocompletethis

HeaterKitinstallation:

•

VGB10547includesanL-shapedttingandO-ringfor

installationonXUV625i.

•

BM23509includesaT-ttingandtwoclampsfor

installationonXUV825i,XUV825EandXUV825M.

•

VGB10548includesastraightttingwiththread

tapeappliedforinstallationonXUV855D,XUV855E,

XUV855M,HPX815EandHPXDiesel.

M172358(14APR20)

1

041420

PN=3

BM23608

MX88017,0000007-19-17OCT19-1/1

FENAFNX,0000156-19-13APR20-1/6

FENAFNX,0000156-19-13APR20-2/6

ContinuedonnextpageFENAFNX,0000156-19-13APR20-3/6

ParkingSafely

Parkthemachinesafely.SeeParkingSafelyinyour

Operator’sManual.

DrainEngineCoolant

NOTE:Drainenginecoolantaspertheinstructions

inyourmachineoperator'smanual.

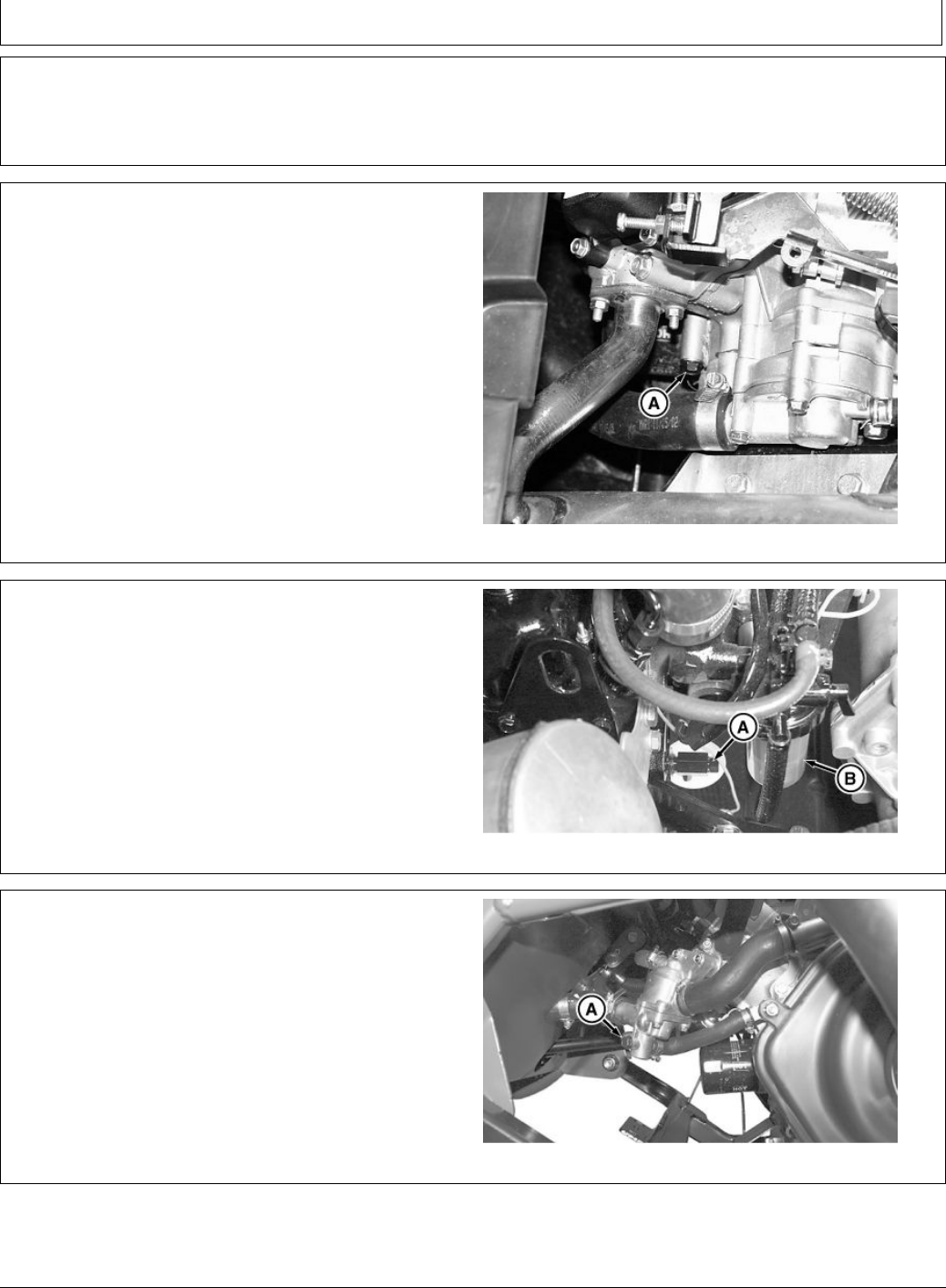

HPXGasandHPX615E

1.Loosendrainscrew(A)ontheleftsideofengine,and

draincoolantintopan.

2.Afterallcoolanthasdrained,tightendrainscrew(A).

A—DrainScrew

MXT008978—UN—12SEP13

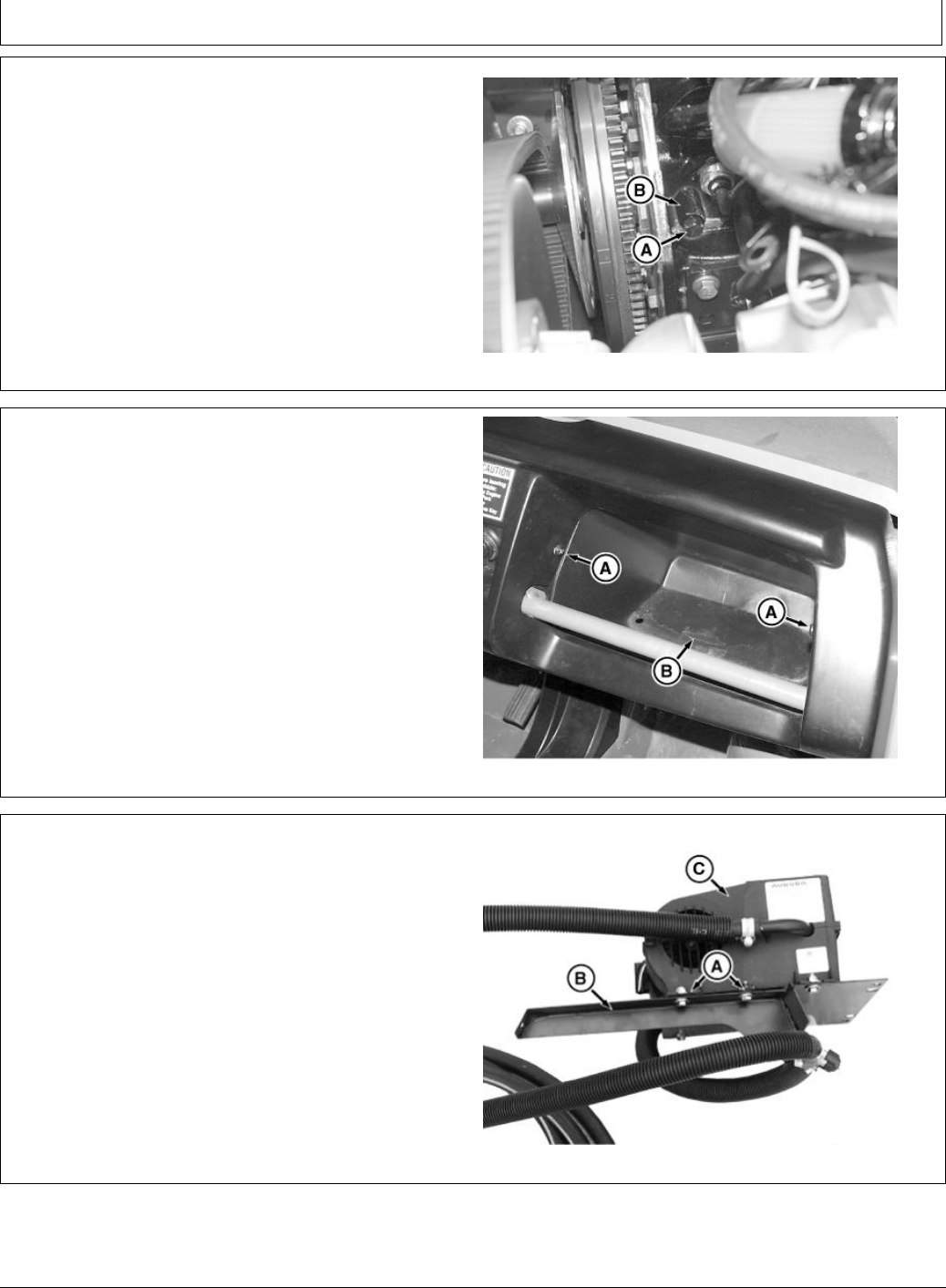

HPXDieselandHPX815E

1.Loosendrainscrew(A)behindthefuellter(B),and

draincoolantintopan.

2.Afterallcoolanthasdrained,tightenthedrainscrew

(A).

A—DrainScrew

B—FuelFilter

MXT015081—UN—15JUL15

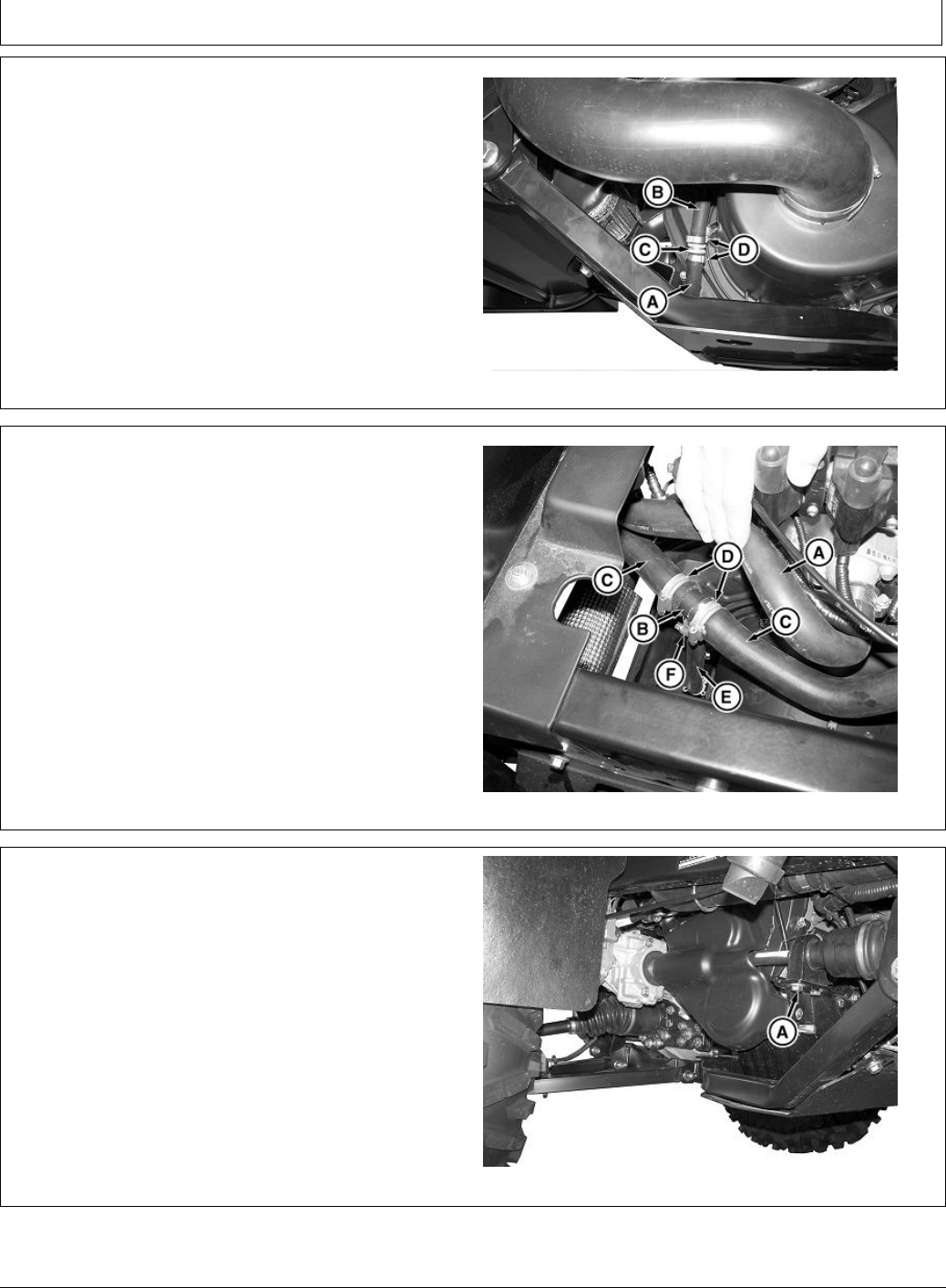

XUV625i

1.Removedrainscrew(A)atbottomofthethermostat

housing,anddraincoolantintopan.

2.Afterallcoolanthasdrained,tightenthedrainscrew

(A).

A—DrainScrew

MXT008980—UN—12SEP13

M172358(14APR20)

2

041420

PN=4

BM23608

FENAFNX,0000156-19-13APR20-4/6

ContinuedonnextpageFENAFNX,0000156-19-13APR20-5/6

XUV825i,XUV825EandXUV825M

1.Cuthose(A)atlocation(B).

A—Hose

B—Location

C—UpperHose

MXT008981—UN—12SEP13

PictureNote:Upperhose(C)raisedforbetterview.

XUV855D,XUV855EandXUV855M

1.Removeandretainthebolt(A)thatsecuresdipstick

tubebracket,andfuellter.

NOTE:Fuellterassemblycanbemovedoutoftheway

withoutdisconnectingfuellines.Itcanbehelpfulto

securefuellterwhenworkingwiththecoolantdrain.

Donotmovethedipsticktubemorethan

necessarytoavoiddamagingoftheO-ring

atthebaseofthetube.

2.Pivotdipsticktube(B),andmovefuellterassembly

outofthewaytoreachthedrainscrewbehindand

belowthefuellter.

MXT008982—UN—12SEP13

A—BoltB—DipstickTube

M172358(14APR20)

3

041420

PN=5

BM23608

FENAFNX,0000156-19-13APR20-6/6

FENAFNX,0000144-19-10APR20-1/9

ContinuedonnextpageFENAFNX,0000144-19-10APR20-2/9

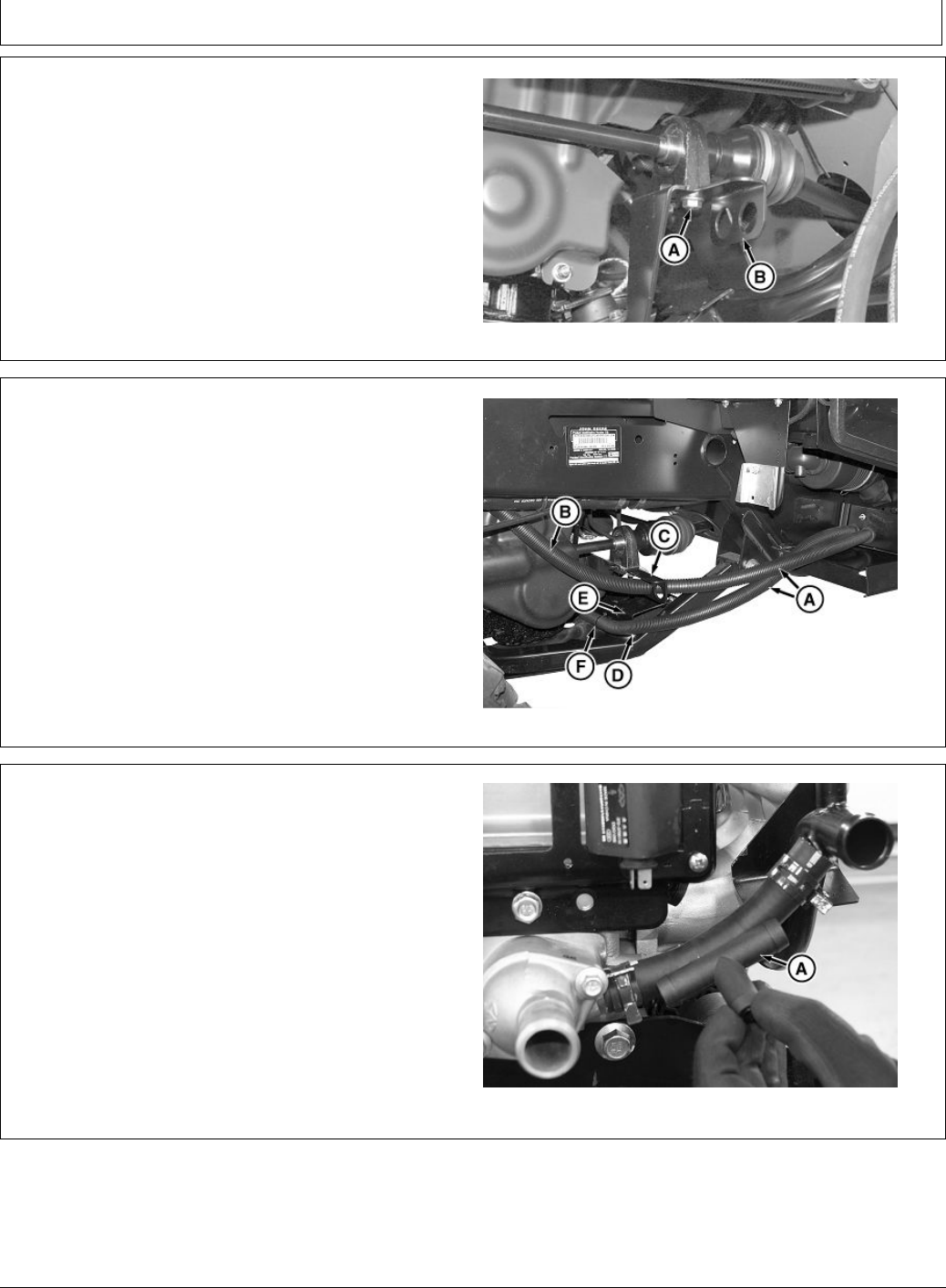

3.Removedrainscrew(A),andallowcoolanttodrain.

4.Whencoolanthasdrained,removehexdrain

extension(B)fromblock.

A—DrainScrew

B—DrainExtension

MXT008983—UN—12SEP13

InstallHeaterUnitandFloorPanel

1.Removeanddiscardtwoscrews(A),andstorage

compartment(B).

A—Screw(2used)B—StorageCompartment

MXT008984—UN—12SEP13

2.Removeandretainhardware(A)attachingthelower

bracket(B)totheheaterunit(C).

A—Hardware

B—LowerBracket

C—HeaterUnit

APY30680—UN—31MAR20

M172358(14APR20)

4

041420

PN=6

BM23608

FENAFNX,0000144-19-10APR20-3/9

ContinuedonnextpageFENAFNX,0000144-19-10APR20-4/9

3.Installheaterunit(A)asshown(withhosesandhose

coversattached),withthelowermountingplate(B)

oftheunitpositionedundergrabhandle(C).Make

surethattherearofthemountingplaterestingonthe

machinefender(D).

A—HeaterUnit

B—LowerMountingPlate

C—GrabHandle

D—Fender

MXT008986—UN—12SEP13

4.Installwireharnessandheaterretainingpanel(A)as

shownwiththestep(B)atthefrontofapanelontop

ofgrabhandle(C).

5.Tilttheheaterunitup,alignouterholesatthefrontof

theheaterplatewithlowerclipsnuts(D)ontheheater

retainingpanel.Installtwohexheadbolts(E),and

M6washers.

A—HeaterRetainingPanel

B—Step

C—GrabHandle

D—ClipNut(2used)

E—HexHeadBolt,M6x16(2

used)

MXT015085—UN—21JUL15

M172358(14APR20)

5

041420

PN=7

BM23608

FENAFNX,0000144-19-10APR20-5/9

FENAFNX,0000144-19-10APR20-6/9

ContinuedonnextpageFENAFNX,0000144-19-10APR20-7/9

6.Looselyinstalllowerbracket(A)totheheaterunitwith

thehardwareremovedearlier.

7.Adjustlowerbrackettopositionheaterunitwiththe

backofbrackettightagainstthefootdeck,andtighten

hardware.

8.Holdbracketrmlyinpositionagainstthefootdeck

andmarkfootdeckatcenterofthelowerhole(B)in

thebracketfordrilling.

9.Centerpunchanddrilla5mm(3/16in)holethrough

thefootdeckatmark.

10.Installaself-threadingscrew,andM6washerthrough

thebracketintothefootdeck.

A—LowerBracketB—LowerHole

MXT008988—UN—12SEP13

11.Presstopofheaterretainingpanel(A)backtoward

theheaterunit(B).Donotforcethepanelbackwards

excessivelysothatthepanelbends.

12.Holdtheupperbracket(C)oftheretainingpanel

upwardagainstthedashpanel.

13.Usingthetwoholesintheupperbracketasaguide,

drilltwo4mm(5/32in)holes(D)throughthedash

panel.Later,thistwoholesareusedfortheinstallation

ofpoprivets.

A—Panel

B—HeaterUnit

C—UpperBracket

D—Hole

MXT008989—UN—12SEP13

14.Removeplasticplugsfromtwoholesatthebaseof

therightsidecloseoutpanel(A),andinstallhose

grommets(B).

A—Panel

B—Grommet(2used)

MXT008990—UN—13SEP13

M172358(14APR20)

6

041420

PN=8

BM23608

FENAFNX,0000144-19-10APR20-8/9

FENAFNX,0000144-19-10APR20-9/9

ContinuedonnextpageFENAFNX,0000145-19-10APR20-1/5

15.Lubricateheaterhoses(A)withsoapywaterorrubber

lubricant,andinstallhosesthroughgrommets(B).Pull

hosesbackthroughgrommets,leavingslackfornal

hoserouting.

16.Determinewhichheaterhoseisconnectedtothe

shutoffvalve,andmarkortagthathoseattheoutside

ofthecloseoutpanelforfuturereference.

A—Hose(2used)B—Grommet(2used)

MXT008991—UN—13SEP13

17.Positionoorcover(A)overhosesonthefootdeck.

Adjusthoselengthasnecessaryforproperrouting.

Donotinstallhardware.

A—FloorCover

MXT008992—UN—12SEP13

InstallFittingsandHoses(HPXGasand

HPX615E)

1.Unplugwiringleadconnector(A)fromthetemperature

sensor(B).

2.Removeandretaintemperaturesensor(B),and

sealingwasher.

A—WiringLeadConnectorB—TemperatureSensor

MXT008993—UN—12SEP13

M172358(14APR20)

7

041420

PN=9

BM23608

FENAFNX,0000145-19-10APR20-2/5

ContinuedonnextpageFENAFNX,0000145-19-10APR20-3/5

NOTE:DonotapplythreadsealanttoeithertheT-adapter

orthetemperaturesensorwheninstalling.

3.Installbrasssealingwasher(A)onthethreadedtting

(B).

NOTE:ThethreadedttingontheT-adapter(C)accepts

a3/8inHexkeywrenchusedfortightening.

4.InstallT-adapterandbrasssealingwasherinthe

cylinderheadport.Positionhosenipple(D),and

tightenthethreadedtting.

Specication

Threaded

Fitting—Torque ..............................................................................75N·m

(55lb·ft)

5.Installoriginaltemperaturesensor(E),andsealing

washer(F)inT-adapter.

Specication

Threaded

Fitting—Torque ..............................................................................60N·m

(44lb·ft)

6.Plugwiringleadconnectortothetemperaturesensor

terminal.

MXT015083—UN—21JUL15

A—BrassSealingWasher

B—ThreadedFitting

C—T-adapter

D—HoseNipple

E—TemperatureSensor

F—SealingWasher

7.Cutthroughreturnradiatorhose(A),andinstallT-tting

(B)includedinthiskitwithtwohoseclamps(C).

A—RadiatorReturnHose

B—T-tting

C—HoseClamp,1-1/2in(2

used)

MXT008995—UN—13SEP13

M172358(14APR20)

8

041420

PN=10

BM23608

FENAFNX,0000145-19-10APR20-4/5

FENAFNX,0000145-19-10APR20-5/5

8.Routeheaterhosesfromtherightsidecloseoutpanel,

betweenanupperframemember(A),andlowerframe

member(B),andintoenginecompartment.

A—UpperFrameMemberB—LowerFrameMember

MXT008996—UN—12SEP13

9.Routeheatershutoffvalvehose(A)overengine,to

thehosenipple(B)onT-adapter.

10.Verifythatheatershutoffvalvehose(A)hasenough

lengthforslackandforsafelysecuringtoother

components.T otthehosenipple(B),cuthoseto

properlength.Installhosenipple(B)usinga25.4mm

(1in)hoseclamp.

11.Cutheatershutoffvalvehose(A)approximately100

mm(4in)fromendofthehosenipple(B).

12.Withthebleederscrew(C)pointedup,installbleeder

T-ttingincludedwiththiskitusinga25.4mm(1in)

hoseclamp.

13.Routeremainingheatershutoffvalvehose(A)over

thecoolantpressurehosetobleederT-tting.

14.Verifythatheatershutoffvalvehose(A)hasenough

lengthforslackandforsafelysecuringtoother

components.T otbleederT-tting,cuthosetoproper

length.InstallonbleederT-ttingusinga25.4mm(1

in)hoseclamp.

MXT008997—UN—13SEP13

A—HeaterShutoffValveHose

B—HoseNipple

C—BleederScrew

M172358(14APR20)

9

041420

PN=11

BM23608

FENAFNX,0000146-19-10APR20-1/5

ContinuedonnextpageFENAFNX,0000146-19-10APR20-2/5

InstallFittingsandHoses(HPXDieseland

HPX815E)

1.Removedraintting(A)fromtheengineblockatthe

leftsideofmachine.Replacewiththestraighttting

(B)includedinadditionalttingkitVGB10548.

A—DrainFitting

B—StraightFitting

MXT008998—UN—12SEP13

2.Locateexistingcoolantreturnhose(A)thatconnects

totheengineblockbehindthethermostat.Cutthrough

thehoseintheareashown(B)neartheprotrusion

(C)ofthebeltguard.

A—ReturnHose

B—PointMarked

C—Protrusion

MXT008999—UN—12SEP13

M172358(14APR20)

10

041420

PN=12

BM23608

FENAFNX,0000146-19-10APR20-3/5

ContinuedonnextpageFENAFNX,0000146-19-10APR20-4/5

3.InstallT-tting(A)includedwiththiskitonthehose

withtwo1-1/2inchhoseclamps.

A—T-tting

MXT009000—UN—12SEP13

PictureNote:Fittingshownwithheaterhoseconnected.

4.Routeheaterhosesfromtherightsidecloseoutpanel,

betweenanupperframemember(A),andlowerframe

member(B)intoenginecompartment.

A—UpperFrameMemberB—LowerFrameMember

MXT009002—UN—12SEP13

M172358(14APR20)

11

041420

PN=13

BM23608

FENAFNX,0000146-19-10APR20-5/5

ContinuedonnextpageBVVMSIT,000021F-19-31MAR20-1/8

5.Routeheatershutoffvalvehose(A)overtheengineto

thestraightttinginstalledintheengineblockdrain.

6.Verifythatheatershutoffvalvehose(A)hasenough

lengthforslackandforsafelysecuringtoother

components.Cuttoproperlengthforstraighttting

installation.Installstraightttingwitha1inhoseclamp.

7.Cutheatershutoffvalvehose(A),andinstallbleeder

T-tting(B)includedwiththiskitsothatbleederscrew

(C)ispointedup.Securewith1inchhoseclamp.

8.Routeremainingshutoffvalveheaterhoseoverthe

coolantpressurehosetobleederT-tting.

NOTE:Beforecuttingheatershutoffvalvehose,verify

thatthehosehasenoughlengthforslackand

forsafelysecuringtoothercomponents.

9.Cutheatershutoffvalvehose(A),andinstallon

bleederT-tting(B)with1inchhoseclamp.

10.Installtiestrapsonheaterhoses,asneeded,to

protecthosesagainstcontactwithmovingparts.

MXT009003—UN—12SEP13

A—HeaterShutoffValveHose

B—BleederT-tting

C—BleederScrew

InstallFittingsandHoses(XUV620i,XUV625i)

1.LocatetheT-tting(A)includedinthiskitandcutthe

threehoseendsattheedgeofthestep-downradius

(B),asshown.

2.DeburrT-ttingasnecessaryaftercutting.

A—T-ttingB—Step-DownRadius

MXT009004—UN—12SEP13

M172358(14APR20)

12

041420

PN=14

BM23608

BVVMSIT,000021F-19-31MAR20-2/8

ContinuedonnextpageBVVMSIT,000021F-19-31MAR20-3/8

3.Cuttwosectionsofthehoseprotector(A)

approximately355mm(14in)long,andslidethem

overthetwoheaterhosesbehindthecloseoutpanel.

4.Routebothheaterhosesthroughtheopeninginthe

driveshaftsupportbracket(B).

5.Continueroutingthehose(C),fromtheheatervalve,

behindthedriveshaftanduptothetopoftheengine.

6.Continueroutingthereturnhose(D)fromthedrive

shaftsupportbracketunderthefrontoftheengine

towardthethermostathousing.

7.Positionbothhosesforbestroutingfromthecloseout

panelthroughthedriveshaftbracket.Repositionthe

hoseprotectorsformaximumprotectionfortheouter

hose,innerhoseatthedriveshaftbracket,andthe

hardware(E)attheframeconnection.

8.Installtiestraps(F)aroundthetwohoses,intwo

places.

MXT009005—UN—12SEP13

A—HoseProtector

B—DriveShaftSupportBracket

C—Hose

D—ReturnHose

E—Hardware

F—TieStrap

NOTE:InstallationofthemodiedT-tting(A)requires

thethermostattoenginehosetobecut.

9.Locatethermostattotheenginehoseandmarkcutline

(B).Markthreeorientationlines(C)toaidininstallation.

A—T-tting

B—CutLine

C—Orientationline

MXT009006—UN—12SEP13

PictureNote:NoteorientationofT-ttingandmarkedhose.

M172358(14APR20)

13

041420

PN=15

BM23608

BVVMSIT,000021F-19-31MAR20-4/8

BVVMSIT,000021F-19-31MAR20-5/8

ContinuedonnextpageBVVMSIT,000021F-19-31MAR20-6/8

10.Removeandretaintwobolts(A)fromthethermostat

housingandbracket.

11.Removethetwoclampsandthermostathose.Cutthe

thermostathoseatthemarkedcutline.

NOTE:ThesmallhoseendontheT-ttingincludedinthis

kitisangledparalleltotheenginecover.Routethe

hosebetweentheenginecover,andclutchcover.

12.InstallT-tting,andtwo1-1/2inchhoseclampson

thethermostathose.

NOTE:Theadditionalhoseprotectorisneeded

wheretheheaterhoseisroutedbetweenthe

engineandclutchcover.

13.Installasectionofthehoseprotectorapproximately

254mm(10in)long,ontotheendoftheheaterreturn

hose.Theninstallthehoseanda1inhoseclamp

ontheT-tting.

MXT009007—UN—12SEP13

A—Bolt

14.Installthermostathose(A)withoriginalhoseclamps.

CheckalignmentofhosesandT-tting,adjustif

necessary.Tightentheallclamps.

15.Slidehoseprotectorontheheaterhose,uptoclamp

atT-tting.

16.Installthermostathousingtobracketwithoriginalbolts.

17.Installheaterhose(B)totheframebracketatthefront

ofanenginewithtiestrap(C).

A—ThermostatHose

B—HeaterHose

C—TieStrap

MXT009008—UN—13SEP13

PictureNote:Correctorientationofassembledcomponents.

Shownwithoptionalhighoutputalternator.

18.Removeandretaintheplug(A),andsealingwasher

fromtherearcylinderhead.

A—Plug

MXT009009—UN—12SEP13

M172358(14APR20)

14

041420

PN=16

BM23608

BVVMSIT,000021F-19-31MAR20-7/8

BVVMSIT,000021F-19-31MAR20-8/8

19.Installbrasssealingwasher(A)onthethreadedtting

(B)oftheT-adapter(C).

NOTE:ThethreadedttingontheT-adapter(C)accepts

a3/8inchwrenchusedfortightening.

20.InstalltheT-adapter(C)andbrasssealingwasher

(A)intothecylinderheadportwheretheplug(D)

wasremovedearlier.Positionthehosenipple(E)as

shownandholdadapterinplacewhiletighteningthe

threadedttingwitha3/8inchwrench.Tightenthe

threadedtting.

Specication

Threaded

Fitting—Torque ..............................................................................75N·m

(55lb·ft)

21.Installtheplugwiththesealingwasher(removed

earlier)intotheopenportoftheT-adapter(C),Tighten

theplug.

Specication

Threaded

Fitting—Torque ..............................................................................60N·m

(44lb·ft)

MXT015084—UN—21JUL15

A—BrassSealingWasher

B—ThreadedFitting

C—T-adapter

D—Plug

E—HoseNipple

22.Finishroutingoftheheaterhose(A)overtothehose

nippleontheT-adapter,underthewiringharness,as

shown.Checkroutingforeliminatingtheexcessive

slack,trimhoselengthifnecessary.Connecttohose

nippletotheT-adapterwith1inchhoseclamp.

23.Locatethehighspotontheheaterhoseandcutthe

hoseinthatspot.Installtwo1inchhoseclamps

ontothecutends.TheninstalltheT-ttingbleeder

(B)includedinthiskit.Rotatethettingsothatthe

bleederscrew(C)isfacingupandtightentheclamps.

24.Secureheaterhosetocoolanthoseatthefrontof

ywheelcoverwithtiestrap.

A—HeaterHose

B—T-ttingBleeder

C—BleederScrew

MXT009011—UN—12SEP13

M172358(14APR20)

15

041420

PN=17

BM23608

FENAFNX,0000147-19-10APR20-1/7

FENAFNX,0000147-19-10APR20-2/7

ContinuedonnextpageFENAFNX,0000147-19-10APR20-3/7

InstallFittingsandHoses(XUV855D,

XUV855EandXUV855M)

IMPORTANT:Avoiddamage!Becarefulnottomove

orchangethealignmentofthepillowblock

wheninstallingthehosebracket.

1.Removeandretaintheouterdriveshaftpillowblock

retainingbolt(A)fromthebracket.

A—Bolt

MXT009012—UN—12SEP13

NOTE:Donotmovepillowblockduringbracket

installation.Ensurethatthebracketisparallel

withthepillowblock,asshown.

2.Installhosebracket(B)underthepillowblockbracket

withapillowblockretainingbolt(A),removedearlier.

Tightenthebolt.

Specication

Bolt—Torque ..................................................................................73N·m

(54lb·ft)

A—Bolt,PillowBlockRetainingB—HoseBracket

MXT009013—UN—12SEP13

3.Cuttwopiecesofthehoseprotector(A)approximately

355mm(14in)long.Slidethemoverthetwoheater

hosesbehindthecloseoutpanelandthroughthehose

bracket(B).Thelongerhose,comingfromtheheater

valve,usestheouterbrackethole.Theshorterreturn

hoseusestheinnerbrackethole.

4.Adjustthehoseprotectorssothatafewinchesof

thehoseprotectorareontherearsideofthehose

bracket,asshown.

A—HoseProtectorB—HoseBracket

MXT009014—UN—13SEP13

M172358(14APR20)

16

041420

PN=18

BM23608

FENAFNX,0000147-19-10APR20-4/7

FENAFNX,0000147-19-10APR20-5/7

ContinuedonnextpageFENAFNX,0000147-19-10APR20-6/7

5.Locatetheexistingcoolanthose(A)abovethedrive

shaftandparkbrakearm.T emporarilyroutetheinner

heaterhose(returnhose)fromthehosebracketup

betweenthedriveshaftandparkbrakearmtocoolant

hose.Allowadequateclearancebehindthedriveshaft

pillowblock.Markacutline(B)onthecoolanthose.

6.Removecoolanthoseandcutthehoseatthemarked

cutline.

7.PositionandorientatetheT-ttingincludedinthis

kitsothatsmallhoseendpointsdownward.Install

T-ttingwithtwo1-1/2inchhoseclamps.

A—CoolantHoseB—CutLine

MXT009015—UN—12SEP13

8.Routetheheaterreturnhose(A)uptoT-tting(B)

includedinthiskitbetweendriveshaftandparkbrake

arm.Keephoselengthasshortaspossiblewithout

kinkingatbend.Cutthehosetolengthandinstallon

T-ttingwith1inchhoseclamp(C).

9.AdjustT-ttingsothatitanglesslightlyoutwardfor

maximizehoseclearance.Tightenthesmallhose

clamprst,thenmovethetwohoseclamps(D)in

positionandtightenthem.

A—ReturnHose

B—T-tting

C—Clamp,1in

D—Clamp,1-1/2in

MXT009016—UN—12SEP13

10.Installthestraighttting(A)includedinadditional

ttingkitVGB10548intothedrainscrewport.Tighten

thetting.

11.Cutasectionofhose(B)includedinthiskit

approximately508mm(20in)long.Installonthe

straightttingwith1inchhoseclamp.

12.Cutasectionofthehoseprotectorapproximately305

mm(12in)longandinstallonthehoseuptoclamp.

13.Reinstallfuellterassemblyanddipsticktubeonto

theiroriginalpositionswithpreviouslyremovedbolt.

A—StraightFitting

B—Hose

MXT009017—UN—12SEP13

M172358(14APR20)

17

041420

PN=19

BM23608

FENAFNX,0000147-19-10APR20-7/7

FENAFNX,0000148-19-10APR20-1/7

ContinuedonnextpageFENAFNX,0000148-19-10APR20-2/7

14.InstallbleederT-tting(A)includedinthiskittothe

bleederhose(B)with1inchhoseclamp.Donot

tightentheclamp.

15.Routetheheaterhose(C)andheaterreturnhose

betweendriveshaftandparkbrakearm,tothetopof

anengine.Installtiestraparoundhosesnearbleeder

T-tting.

16.RoutethehosewithbleederT-ttingalongthereturn

hoseasshown.Positiontheheaterhoseatbleeder

T-tting.

17.Adjustthehosesuntilthebleederscrew(D)isatthe

highestpointofreturnhose.Trimexcessheaterhose

whenthebleederhoseandheaterhoseareconnected.

18.InstallheaterhoseonbleederT-tting.Tightenboth

hoseclamps.

19.Installbleederandheaterhosestotheintakehose(E)

withthetwotie-straps(F)asshown.Tiestrapsmustbe

assembledtoeachothertocreateonelongtiestrap.

MXT014970—UN—11AUG15

A—BleederT-tting

B—BleederHose

C—HeaterHose

D—BleederScrew

E—IntakeHose

F—TieStrap

InstallFittingsandHoses(XUV825i,XUV825E

andXUV825M:SerialNumber—80000)

NOTE:Thesemachineshavezinc-plated(gold

colored)solidcoolanttube.

IMPORTANT:Avoiddamage!Becarefulnottomove

orchangethealignmentofthepillowblock

wheninstallingthehosebracket.

1.Removeandretainouterdriveshaftpillowblock

retainingbolt(A)frombracket.

A—PillowBlockRetainingBolt

MXT009019—UN—12SEP13

NOTE:Donotmovepillowblockduringbracket

installation.Bracketmustbeparallelwith

thepillowblock,asshown.

2.Installhosebracket(B)underthepillowblockbracket

withthepillowblockretainingbolt(A).Tightenthebolt.

Specication

Bolt—Torque ..................................................................................73N·m

(54lb·ft)

A—PillowBlockRetainingBoltB—HoseBracket

MXT009020—UN—12SEP13

M172358(14APR20)

18

041420

PN=20

BM23608

FENAFNX,0000148-19-10APR20-3/7

FENAFNX,0000148-19-10APR20-4/7

ContinuedonnextpageFENAFNX,0000148-19-10APR20-5/7

3.Usetwopiecesofthehoseprotector(A),andslide

themoverthetwoheaterhosesbehindthecloseout

panel.

4.Installtheouterheaterhose(B)throughtheinnerhole

onthehosebracket(C).Routehoseoverthetopof

theengineasshown.

5.Installtheinnerheaterhose(D)downneartheframe

plate(E).Securehosewiththetiestrap(F)tothe

frameplate.

A—HoseProtector

B—OuterHeaterHose

C—HoseBracket

D—InnerHeaterHose

E—FramePlate

F—TieStrap

MXT009021—UN—13SEP13

6.Locatecoolanthoserunningparalleltovalvecover.

Trim3inchesfromtheendofsmalldiameterhose(A).

A—SmallDiameterHose

MXT009309—UN—21SEP13

7.Installlargediameterhose(A)onT-tting(B)included

inthiskit.InstallbleederT-tting(C)includedinthis

kitontoendofthecuthose(D).

8.Routeouterheaterhose(E)(hoseleadingtoengine)

aroundthefrontofbracket(F).ConnecttoT-tting

withclamps.

A—LargeDiameterHose

B—T-tting

C—T-tting,Bleeder

D—CutHose

E—OuterHeaterHose

F—Bracket

MXT009310—UN—21SEP13

M172358(14APR20)

19

041420

PN=21

BM23608

FENAFNX,0000148-19-10APR20-6/7

FENAFNX,0000148-19-10APR20-7/7

ContinuedonnextpageFENAFNX,0000157-19-13APR20-1/7

9.Routeinnerheaterhose(A)aroundtoleftsideof

machine.Cuta205mm(8in)pieceofradiatorhose

(B)fromshortextensionheaterhoseincludedinthis

kit.Connectwithextensionconnector(C)andtwo

crimpclamps(D).

A—InnerHeaterHose

B—RadiatorHose

C—Connector

D—CrimpClamps

MXT009024—UN—12SEP13

NOTE:Ifnecessary,haveanassistantholdupperradiator

hose(A)awayfromareawheninstallingT-tting

(B)includedinadditionalttingkitBM23509.

10.InstallT-tting(B)ontohoses(C)withtwoclamps(D).

11.Installshortextensionpieceofhose(E)ontothe

bottomofT-tting(B)withclamp(F).

A—UpperRadiatorHose

B—T-tting

C—Hoses

D—Clamp

E—Hose

F—Clamp

MXT009025—UN—13SEP13

InstallFittingsandHoses(XUV825i,XUV825E

andXUV825M:SerialNumber80001—)

NOTE:Thesemachineshaveablacksolidcoolanttube.

IMPORTANT:Avoiddamage!Becarefulnottomove

orchangethealignmentofthepillowblock

wheninstallingthehosebracket.

1.Removeandretainouterdriveshaftpillowblock

retainingbolt(A)frombracket.

A—PillowBlockRetainingBolt

MXT009019—UN—12SEP13

M172358(14APR20)

20

041420

PN=22

BM23608

FENAFNX,0000157-19-13APR20-2/7

FENAFNX,0000157-19-13APR20-3/7

ContinuedonnextpageFENAFNX,0000157-19-13APR20-4/7

NOTE:Donotmovepillowblockduringbracket

installation.Bracketmustbeparallelwith

thepillowblock.

2.Installhosebracket(B)underthepillowblockbracket

withthepillowblockretainingbolt(A).Tightenthebolt.

Specication

Bolt—Torque ..................................................................................73N·m

(54lb·ft)

A—PillowBlockRetainingBoltB—HoseBracket

MXT009020—UN—12SEP13

3.Usetwopiecesofthehoseprotector(A)andslidethem

overthetwoheaterhosesbehindthecloseoutpanel.

4.Installtheouterheaterhose(B)throughtheinnerhole

onthehosebracket(C).Routehoseoverthetopof

theengineasshown.

5.Installtheinnerheaterhose(D)downneartheframe

plate(E).Securehosewiththetiestrap(F)tothe

frameplate.

A—HoseProtector

B—OuterHeaterHose

C—Bracket

D—InnerHeaterHose

E—FramePlate

F—TieStrap

MXT009021—UN—13SEP13

6.Trim1.25inchesfromthehoseforinstallationof

T-tting(A)includedinthiskitinareashown.

A—T-tting

MXT009307—UN—21SEP13

PictureNote:Shownwithengineremoved.

M172358(14APR20)

21

041420

PN=23

BM23608

FENAFNX,0000157-19-13APR20-5/7

FENAFNX,0000157-19-13APR20-6/7

FENAFNX,0000157-19-13APR20-7/7

7.InstallT-tting(A)andheaterhose(B)ontothehose

withclamps(C).Ifnecessary,installT-tting(A)by

looseningboltsonthesolidcoolantline,andthen

installtomanifold.

A—T-tting

B—HeaterHose

C—Clamp(3used)

MXT009308—UN—21SEP13

8.Routeinnerheaterhose(A)aroundtoleftsideof

machine.Cuta205mm(8in)pieceofradiatorhose

(B)fromtheshortextensionoftheheaterhosesection

includedinthiskit.Connectwithextensionconnector

(C),andtwocrimpclamps(D).

A—InnerHose

B—RadiatorHose

C—ExtensionConnector

D—CrimpClamp(2used)

MXT009024—UN—12SEP13

NOTE:Ifnecessary,haveanassistantholdupperradiator

hose(A)awayfromareawheninstallingT-tting

(B)includedinadditionalttingkitBM23509.

9.InstallT-ttingontohoses(C)withtwoclamps(D).

10.Installshortextensionpieceofhose(E)ontobottom

ofT-ttingwithclamp(F).

A—UpperRadiatorHose

B—T-tting

C—Hose

D—Clamp(2used)

E—Hose

F—Clamp

MXT009025—UN—13SEP13

M172358(14APR20)

22

041420

PN=24

BM23608

BVVMSIT,0000228-19-25MAR20-1/1

PreparetoBleedAirfromSystem(AllModels)

1.Recoverdrainedcoolantfromthedrainpanand

transfertocontainersasneededfortherellingsystem.

2.Placedrainpanbackundertheenginetorecover

coolantlostduringbleedprocedure.

3.Removeoorcover.

4.Removemountingscrewsfromheaterretainingpanel

andlowerbracket.

5.Removetheheaterunit(A)withhosesattached.

6.Placetheheaterunitontheoor.

7.Withtheopenshutoffvalve(B),llradiatorand

recoverytanktotheupperline.

A—HeaterUnit

B—ShutoffValve

MXT009026—UN—12SEP13

M172358(14APR20)

23

041420

PN=25

BM23608

BVVMSIT,0000223-19-31MAR20-1/1

BleedAirfromSystem(AllHPX)

NOTE:Monitorcoolantlevelinradiatorduringbleed

procedure.Makesurethatitdoesnotfalltoolow.

Addcoolantasperrequirementforpreventing

theairentryintothesystem.

1.Openbleedscrewonthegasolineengineintake

manifold(A),oronthedieselenginethermostat

housing(B),untiluidcomes,withnoairbubbles.

Closethebleedscrew.

2.Fillcoolantuptotheupperlineoftheradiator.

3.Openbleedscrew(C)onthebleedteeuntiluid

comesout,withnoairbubblesorsoundofair

escaping.Closethevalve.

4.Shakeheaterunitandheaterhosesfordislodgingthe

airthatistrapped.

5.Openbleedscrew(C)onthegasolineengineintake

manifold(A),oronthedieselenginethermostat

housing(B),untiluidcomes,withnoairbubbles.

Closethebleedscrew(C).

6.Fillcoolantuptotheupperlineoftheradiator.Secure

theradiatorcap.

NOTE:Occasionallyshaketheheaterandheaterhoses

astheengineiswarminguptohelpdislodge

anyairstilltrappedinthesystem.

7.Fillthecoolantuptothetoplineoftheoverowbottle.

8.Startandrunengineuntilfancycles.Ifoverheatlight

doesnotcomeon,unitisproperlybled.

IMPORTANT:AvoidDamage!Ifoverheatlightcomes

on-Shutoffengineandallowittocool.Make

surethattheoverowbottleisfull,asthesystem

pullscoolantfromoverowbottleduringcool

down,helpingtoeliminateairinthesystem.

Whenengineiscool,repeatbleedprocedure.

MXT009027—UN—12SEP13

PictureNote:Gasolineengineshown.

MXT009028—UN—12SEP13

PictureNote:Dieselengineshown.

A—IntakeManifold

B—ThermostatHousing

C—BleedScrew

M172358(14APR20)

24

041420

PN=26

BM23608

ContinuedonnextpageFENAFNX,0000158-19-13APR20-1/2

BleedAirfromSystem(XUVGasEngine)

IMPORTANT:Avoiddamage!Usingincorrectcoolant

mixturecandamagetheradiator:

•Donotoperateengineinabsenceof

coolantorwithplainwater.

•Useantifreezeapprovedforusein

aluminumengines.

•Donotexceeda50%antifreezemixture

forthecoolant.

•Donotpourcoolantorwaterintoradiator

whenengineishot.

•DonotaddStopLeakorotheradditives.

NOTE:JohnDeereCool-Gard™coolantisrecommended

whenaddingcoolanttothecoolingsystem.

Followtheinstructiononthecontainerfor

thecorrectmixtureratio.

XUV620i,XUV625i

1.Raisecargobox.

IMPORTANT:Avoiddamage!Donotremovewashers

fromtoporbottomofthebanjotting.

NOTE:Tomaintainanadequatelevelandpreventthe

airentryintothesystem,monitorcoolantlevelin

radiator,andaddcoolantifnecessary.

2.Loosenenginebleedbolt(A)atthebanjottingon

theintakemanifold(fourfullturnsfromtight).Donot

removebolt,orwashers(B)atthebanjotting.

3.Loosenthebleedscrew(C)atthebleedtee.Donot

removethescrew.

4.Dislodgeairfromthesystembyshakingheater,and

hoses.

5.Maintainthecoolantlevelintotheradiatorandllthe

radiatorwithcoolant,ifnecessary.

6.Allowcoolanttorunoutofbothbleedlocationsuntil

coolantisrunningclear,withnoairbubblesandno

soundsofairescaping.Closebothbleeders.

7.Fillradiatorandrecoverytanktotheupperline,and

secureradiatorcap.

MXT009029—UN—12SEP13

A—BleedBolt

B—Washer(2used)

C—BleedScrew

8.Startengineandrunatlessthanfullthrottletowarmup.

NOTE:Tomaintainanadequatelevel,monitorcoolant

levelintherecoverytankduringwarm-up,and

addcoolant,ifnecessary.Warmupphase

cantakeseveralminutes.

9.Runengineuntilcoolingfanstarts,shakeheaterand

hosesperiodicallytodislodgeair.

CAUTION:Avoidinjury!Radiatorcanbehot.

Donotreachdownfromthetopoftheradiator

tochecklowerhosetemperature.

10.Whenfancomeson,immediatelychecktemperature

ofcoolanthoseatbottomofradiator.

1.Ifthehoseiscold,shutofftheengineandlet

enginecool.Monitorcoolantlevelintherecovery

tankandaddasneeded.Whenengineiscool,

llradiatorandrecoverytanktoupperlinesand

securewithcaps.Thenrepeatbleedprocedure.

Shakehosesandheaterwhenbleeding.

2.Ifthehoseiswarm/hot,reduceenginespeedto

idle,andcontinuerunningmachineuntilfanshuts

off,thencyclesbackonagain.Ifnotemperature

warninglighthascomeon,systemisbledproperly.

Shutofftheengineandletcooldown,monitoring

coolantlevelintherecoverytank.Fillrecovery

tanktotheupperline,ifnecessary.

Cool-GardisatrademarkofDeere&Company

M172358(14APR20)

25

041420

PN=27

BM23608

FENAFNX,0000158-19-13APR20-2/2

XUV825i,XUV825EandXUV825M.

1.Raisecargobox.

2.Loosenbleedscrew(A)locatedinT-ttingconnecting

hoses(B).

3.Removeradiatorcapandaddrecommendedcoolant

mixturetoradiatoruntilcoolantrunsoutofthebleed

port.

4.Tightenthebleedscrew(A).

5.Addadditionalcoolantmixturetoradiatoruntilcoolant

runsoutoftheoverowportandintotherecoverytank.

6.Installradiatorcap.

IMPORTANT:Avoiddamage!Positionhoseslightly

abovebottomoftherecoverytank.Donotallow

thehosetocontactbottomoftherecoverytank

orbendupwardsoutofthecoolant.

7.Removerecoverytankcap,andaddcoolantmixture

totherecoverytankuntilitisapproximatelyhalffull.

8.Installrecoverytankcap.

IMPORTANT:Avoiddamage!Ifcoolanttemperature

indicatorcomesonwhileengineisrunning,stop

engineandaddmorecoolantmixturetoradiator.

9.Startandrunengineatmediumspeeduntilupper

andlowerradiatorhoseshavebecomewarm(10—15

minutes).Warmhosesindicatethatthethermostat

hasopenedandcoolantiscirculating.

10.Allowenginetocool.

11.Loosenbleedscrew(A),andallowairtobubbleout

untilairbubblesarenolongervisibleatthebleedport.

Tightenbleedscrewcompletely.

MXT009030—UN—12SEP13

A—BleedScrew

B—Hoses

12.Removeradiatorcapandaddrecommendedcoolant

mixturetoradiatoruntilcoolantrunsoutoftheoverow

port,andintotherecoverytank.

13.Installtheradiatorcap.

14.Runengineuntilcoolingfanstarts,indicatingthat

theengine,andcoolanthasreachedoperating

temperature.

15.Stopengineandremovethekey.

16.Allowenginetocoolandsuctionbackanyneeded

coolantfromtheoverowrecoverytank.Fillrecovery

tanktotheupperline,ifnecessary.

M172358(14APR20)

26

041420

PN=28

BM23608

BVVMSIT,0000225-19-31MAR20-1/1

ContinuedonnextpageBVVMSIT,0000226-19-25MAR20-1/2

BleedAirfromSystem(XUVDieselEngine)

NOTE:Monitorcoolantlevelinradiatorduringbleed

procedure.Makesurethatitdoesnotfalltoo

low.Addcoolantasperrequirementandprevent

theairentryintothesystem.

1.Openthermostathousingbleedscrew(A)andbleed

screw(B)onbleedteefourturns.

2.Dislodgeairfromthesystembyshakingheaterand

hoses.Allowamplecoolanttorunthroughsystem

whenbleeding.

3.Maintainadequatelevelofcoolantinradiatorandadd

coolant,ifnecessary.

4.Whenclearcoolantiscomingfrombothlocations,and

noairbubblesorsoundsofairescaping,tightenboth

bleedscrew(B).

5.Fillradiatorandcoolantrecoverytanktotheupper

line,andsecureradiatorcap.

NOTE:Tomaintainanadequatelevel,monitorcoolant

levelintherecoverytankduringwarm-up,and

addcoolantifnecessary.Warmupphase

cantakeseveralminutes.

6.Startengine,andrunatfullthrottleuntilfanmotor

cycleson.

a.Iftheenginetemperaturewarninglightcomeson

beforefancycleson,shutdownengineimmediately

andallowenginetocool.Monitorcoolantlevelin

MXT009031—UN—12SEP13

A—ThermostatHousingBleed

Screw

B—BleedScrew

therecoverytankduringcooldownandaddcoolant,

asneeded.Coolantdrawnintotheengineduring

cool-downhelpstodisplacetrappedair.When

engineiscooleddown,llradiatorandrecovery

tanktoupperlinesandtightenthecaps,thenrepeat

bleedprocedure.Shakehosesandheaterwhile

bleeding.

b.Ifnoenginewarninglightcomeson,reduceengine

speedtoidle.Continuerunninguntilfancycles

onagain,thenturnoffengineandallowtocool.

Monitorrecoverytankduringcool-down,add

coolantifnecessarytotheupperline.

ReplaceComponentsAfterBleedProcedure

(AllModels)

1.Installheaterunitandlowerbracketandsecurewith

originalhardware.

2.Installoorpanelandfastentofootdeckinposition

marked(A)withthehexheadbolt,M6x20andM8

washerfromthetop,andM6washerandM6locknut

frombelow.

3.Fastenoorpaneltotherightsidecloseoutpanelin

positionmarked(B)withthehexheadbolt,M6x16

andM6washerfromtheinside,andM6washerand

M6locknutfromtheoutside.Tightenhardware.

A—MarkedPositionB—MarkedPosition

MXT009032—UN—12SEP13

M172358(14APR20)

27

041420

PN=29

BM23608

BVVMSIT,0000226-19-25MAR20-2/2

BVVMSIT,0000227-19-31MAR20-1/6

ContinuedonnextpageBVVMSIT,0000227-19-31MAR20-2/6

4.Secureupperbracket(A)ofheaterretainingpanel

todashpanel,andsecurewithtwopoprivets(B)in

holesdrilledearlier.

A—UpperBracketB—PopRivets

MXT009033—UN—13SEP13

ConnectElectricalComponentsand

CompleteInstallation

NOTE:Theplugconnectorsatthefrontoftheheater

retainingplateconnectstothefanswitchinthe

paddedheatercover.Theplugconnectorson

thetwolongerwiringharnessesatthebackof

theheaterretainingpanelconnecttothepower

sourceandheaterblowermotor.

1.Routewiringharness(A)fromtheheaterunit(B)

underMFWDlinkage(C),andbundlewithmainwiring

harness(D)acrosstoleftsideofmachine.

A—WiringHarness

B—HeaterUnit

C—MFWDLinkage

D—MainWiringHarness

MXT009034—UN—12SEP13

2.Locatetheconnectorplug(A)withyellowandblack

wiresfrommainwiringharness.Connectittothe

heaterharnessconnectorplug(B)withredandbrown

wires.Install5Afuseinthefuseholder(C)ofthe

heaterwiringharness.

3.Secureheaterwiringharnesstomainharnesswithtie

strapsasnecessarytopreventcontactwithmoving

parts.

A—ConnectorPlug

B—HeaterHarnessConnector

Plug

C—FuseHolder

MXT009035—UN—12SEP13

M172358(14APR20)

28

041420

PN=30

BM23608

BVVMSIT,0000227-19-31MAR20-3/6

BVVMSIT,0000227-19-31MAR20-4/6

ContinuedonnextpageBVVMSIT,0000227-19-31MAR20-5/6

4.Plugconnectoronshortwiringharness(A)fromheater

intoconnectorterminals(B)atrearoftheheaterunit

(C).

A—WiringHarness

B—ConnectorTerminal

C—HeaterUnit

MXT009036—UN—13SEP13

5.Plugheaterconnectors(A),and(B)fromthefrontof

heaterretainingpanelintothefanswitchconnectors

(C)insidepaddedheatercover(D).

A—HeaterConnector

B—HeaterConnector

C—FanSwitchConnector

D—HeaterCover

MXT009037—UN—12SEP13

6.Setpaddedheatercover(A)ontopoftheheater

bracket,andsecurewithtwohexheadbolts,M6x20

(B),andM6washers.

A—HeaterCoverB—HexHeadBolt,M6x20(2

used)

MXT009038—UN—12SEP13

M172358(14APR20)

29

041420

PN=31

BM23608

BVVMSIT,0000227-19-31MAR20-6/6

7.Removehexheadbolt,M6x16,andM6washerfrom

theclipnut(A)intheupperbracketofafrontretaining

panel.

8.Placepaddedheaterpanel(B)overtheupperbracket

andsecurethroughtheheaterpanel,andclipnutin

theupperbracketwithoriginalhardware.

9.Turnontheignitionswitchandtesttheheaterblower

fanswitchforproperoperation.Bloweronlyoperates

whenthekeyswitchisinONposition.

A—ClipNut

B—HeaterPanel

MXT009039—UN—13SEP13

M172358(14APR20)

30

041420

PN=32