Easy5 2021.3

Gas Dynamics Library User Guide

For Windows

®

and Linux

®

Main Index

Worldwide Web

www.mscsoftware.com

Support

http://www.mscsoftware.com/Contents/Services/Technical-Support/Contact-Technical-Support.aspx

Disclaimer

This documentation, as well as the software described in it, is furnished under license and may be used only in accordance with the

terms of such license.

MSC Software Corporation reserves the right to make changes in specifications and other information contained in this document

without prior notice.

The concepts, methods, and examples presented in this text are for illustrative and educational purposes only, and are not intended

to be exhaustive or to apply to any particular engineering problem or design. MSC Software Corporation assumes no liability or

responsibility to any person or company for direct or indirect damages resulting from the use of any information contained herein.

User Documentation: Copyright © 2021 MSC Software Corporation. Printed in U.S.A. All Rights Reserved.

This notice shall be marked on any reproduction of this documentation, in whole or in part. Any reproduction or distribution of this

document, in whole or in part, without the prior written consent of MSC Software Corporation is prohibited.

This software may contain certain third-party software that is protected by copyright and licensed from MSC Software suppliers.

Additional terms and conditions and/or notices may apply for certain third party software. Such additional third party software terms

and conditions and/or notices may be set forth in documentation and/or at

http://www.mscsoftware.com/thirdpartysoftware (or successor

website designated by MSC from time to time). Portions of this software are owned by Siemens Product Lifecycle Management, Inc.

© Copyright 2021

The MSC Software logo, MSC, MSC Adams, MD Adams, Adams and Easy5 are trademarks or registered trademarks of MSC Software

Corporation and/or its subsidiaries in the United States and other countries. Hexagon and the Hexagon logo are trademarks or

registered trademarks of Hexagon AB and/or its subsidiaries. NASTRAN is a registered trademark of NASA. FLEXlm and FlexNet

Publisher are trademarks or registered trademarks of Flexera Software. Parasolid is a registered trademark of Siemens Product

Lifecycle Management, Inc. All other trademarks are the property of their respective owners.

Use, duplicate, or disclosure by the U.S. Government is subjected to restrictions as set forth in FAR 12.212 (Commercial Computer

Software) and DFARS 227.7202 (Commercial Computer Software and Commercial Computer Software Documentation), as

applicable.

September 14, 2021

Corporate Europe, Middle East, Africa

MSC Software Corporation MSC Software GmbH

5161 California Ave, Suite 200 Am Moosfeld 13

University Research Park 81829 Munich, Germany

Irvine, CA 92617 Telephone: (49) 89 431 98 70

Email: americas.contact@mscsoftware.com

Japan Asia-Pacific

MSC Software Japan Ltd. MSC Software (S) Pte. Ltd.

KANDA SQUARE 16F 100 Beach Road

2-2-1 Kanda Nishikicho, Chiyoda-ku #16-05 Shaw Tower

Tokyo 101-0054, Japan Singapore 189702

Telephone: (81)(3) 6275 0870 Telephone: 65-6272-0082

Email: MSCJ.Mark[email protected] Email: AP[email protected]

Main Index

Documentation Feedback

At MSC Software, we strive to produce the highest quality documentation and welcome your feedback.

If you have comments or suggestions about our documentation, write to us at:

documentation-

.

Please include the following information with your feedback:

Document name

Release/Version number

Chapter/Section name

Topic title (for Online Help)

Brief description of the content (for example, incomplete/incorrect information, grammatical

errors, information that requires clarification or more details and so on).

Your suggestions for correcting/improving documentation

You may also provide your feedback about MSC Software documentation by taking a short 5-minute

survey at:

http://msc-documentation.questionpro.com.

Note: The above mentioned e-mail address is only for providing documentation specific

feedback. If you have any technical problems, issues, or queries, please contact

Technical

Support

.

Main Index

Main Index

Contents

Gas Dynamics Library User Guide

Contents

1 Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Key Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Formulation and Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Network Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Flowstream Identification—Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Species Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Global Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Component Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

One-Dimensional Body Dynamics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Boundary Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Forces and body dynamics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compressor, Fan & Turbine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Directional Control Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heat Exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Minor Losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Nodes and volumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Orifice and Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pipes, lines and tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Valves (each configurable as Resistive or Storage/Resistive). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Equations of State in the Gas Dynamics Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Guidelines for Building and Analyzing GD Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Error Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Model Operating Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Index

Gas Dynamics Library User Guide

vi

Steady-State Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 Tutorial

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

The Conceptual Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Creating the Easy5 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adding Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Making Connections: Ports and Their Significance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Entering Data into the Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Determining an Initial Operating Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Simulating the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Using Easy5 to Analyze a More Complex System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3 Frequently Asked Questions

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4 Nodes and Volumes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Formulation and Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fundamental Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Equation of State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Equations of Continuity- Non-condensible gas species . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Equations of Continuity- Condensible gas species . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Condensation Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Equation of Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Switch State Rate Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Guidelines for Component Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5 Orifices and Valves

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Fundamental Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Orifice flow regimes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Solution of the orifice equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Main Index

vii

Contents

Switch State Rate Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Valve/Duct Area Models (Components VD and VI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Poppet Valve Area (Component PA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Component Selection- Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Pipes and Flow Resistances

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Discretization of PC and PX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Fundamental Equations- Lumped Parameter, Transient Momentum . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Equations of Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Condensation Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Equation of Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Heat Transfer Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Equation of Momentum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Switch State Rate Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Method of Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Flow Resistances and the Minor Loss group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Guidelines for Component Selection and Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7 Heat Exchangers

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Heat Exchangers Based on Effectiveness Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Gas/Gas Heat Exchanger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Gas/Liquid Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Limitations of Transient Analysis Using Effectiveness Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Heat Exchangers- Single Pressure State, Discretized Temperature Array . . . . . . . . . . . . . . . . . . . . . . . . 81

Equations of Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Condensation Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Equation of Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Transient Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Heat Exchangers- Discretized Pressure and Temperature Vector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Heat Transfer Coefficient Calculation (Components HE, HF, HS and HT) . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Heat Exchanger Flow Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Tabular Correlation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Analytical Correlation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Main Index

Gas Dynamics Library User Guide

viii

Steady-momentum pipe model (equivalent pipe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Zero-resistance flow-through. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Transient-momentum pipe model (equivalent pipe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Switch State Rate Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Guidelines for Component Selection and Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8 Chemical Reactors

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Mathematical Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Stoichiometric Coefficients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Extent of Reaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Equilibrium Extent of Reaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Adiabatic Reaction Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Non-adiabatic Reactor Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Guidelines for Component Selection and Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9 Compressors, Fans, & Turbines

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Compressor Based upon Corrected Flow Map (CN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Compressor Based upon Map of Polytropic Efficiency and Polytropic Head (CP) . . . . . . . . . . . . . . . . . . . . 96

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Turbine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

A Gas Properties

Accessing Gas Properties from FORTRAN or Macro Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Molar Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Enthalpy () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Entropy () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Ideal Gas Heat Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Non-Ideal Gas Heat Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

ThermalConductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Partial Derivatives of Molar Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Gas Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Species Densities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Main Index

ix

Contents

Partial Derivatives of Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Densities and Partial Derivatives of Species Densities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Temperature Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Total Pressure and Mole Fraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Critical Properties for Non-Ideal Gas Laws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

User-Defined Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

User-Defined Gas Laws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Internal Conversion Constants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Gas Dissociation Modeled by User-Defined Molecular Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Main Index

Gas Dynamics Library User Guide

x

Main Index

Chapter 1: Overview

MSC Nastran Implicit Nonlinear (SOL 600) User’s GuideGas Dynamics Library User Guide

1

Overview

Introduction 2

Key Features 2

Formulation and Terminology 3

Network Considerations 3

Component Types 13

Equations of State in the Gas Dynamics Library 16

Guidelines for Building and Analyzing GD Models 17

References 20

Main Index

Gas Dynamics Library User Guide

Introduction

2

Introduction

The Gas Dynamics (gd) library is a collection of components designed to model compressible gas systems,

including pneumatic systems, environmental control systems, and gas transmission. Either real gases and

ideal gases can be modeled, and humidity effects are included. The transient forms of the energy and species

mass conservation equations are modeled, with gas composition allowed to vary throughout a system.

This manual describes the application of Easy5 to modeling and analyzing single-phase gas dynamics systems.

Characteristics of the Easy5 gd component library are discussed, and examples of its use for steady-state and

transient analyses are demonstrated.

Note that all assumptions and approaches associated with the GD component mathematical models do not

in any way reflect the presumption that other approaches or mathematical models are any less correct. You

are encouraged to use Easy5’s library component development utilities to develop new components or to

modify existing components as deemed necessary.

This documentation assumes that the user is familiar with the use of Easy5, and is conversant with the

terminology in the Easy5 User Guide.

Key Features

The GD library currently consists of components that model a variety of devices such as heat exchangers,

ducts, valves, orifices, actuators, compressors, turbines, pumps, and fans. Important features include:

Rigorous formulation of the conservation equations for species mass, internal energy, and

momentum.

Choice of ideal or real gas law.

The gas composition can vary continuously within a model.

Forward or reverse flow is considered in all components.

Condensation/evaporation of water will be considered.

Easy5 switch states efficiently model discontinuities.

Units

The GD library can use either metric units or English units. Internal calculations are performed with MKS

units. The specification of the desired units system is done with the UN parameter in the GP component.

One and only one GP component must be added to each model that uses GD library components. The major

quantities for each system are shown in

Table 1-1.

Table 1-1 Units of Measure in GD Library

Quantity Metric unit English unit MKS unit

Temperature

o

C

o

F K

Mass flow kg/s lbm/s kg/s

Pressure bar psia N/m

2

Length cm, m in, ft m

Main Index

3

Chapter 1: Overview

Formulation and Terminology

Formulation and Terminology

Rigorous models of compressible gas dynamics must consider variations in gas density and the gas kinetic

energy. Classical compressible fluid flow treatments accomplish this by defining “total” (or stagnation)

quantities such as total temperature, pressure and density (1,2). The use of “total” quantities is convenient as

long as the gas properties are considered perfect (it obeys the ideal gas law and has constant heat capacity),

but is not as convenient when more sophisticated equation of states are used.

Some components in the Easy5 Gas Dynamics library use static quantities and explicitly consider kinetic

energy. For this reason, kinetic energy is one of the quantities passed between GD library components in the

ported connections. If the ported kinetic energy output (KF_PortName or KR_PortName) is zero, then total

or stagnation temperature is being output at that port. Otherwise the temperature is usually, but not always,

static. For non-ideal gases, the kinetic energy output is sometimes used to port additional information about

the non-ideality to the connected component.

The composition of multi-species gases is modeled through the use of partial pressures and species flow

rates. The partial pressure P

k

of a gas is defined as P

k

= Y

k

P where the gas phase mole fraction of species

k is

where n

k

is the number of moles of species k. For a single-species gas, the pressure and species partial pressure

are the same.

Network Considerations

The equations that model continuity, energy, or momentum effects are of fundamental importance in

designing and implementing a mathematical model of a GD component. Another factor of equal

importance, however, is the overall component-network design. The way in which the individual

components communicate (pass information to one another) directly affects the utility of the library.

Area cm

2

, m

2

in

2

, ft

2

m

2

Volume m

3

ft

3

m

3

Volumetric flow m

3

/s ft

3

/s m

3

/s

Heat capacity J/K Btu/

o

R J/K

Thermal conductance W/K Btu/hr/

o

R W/K

Heat transfer coefficient W/m

2

/K Btu/ft

2

/hr/

o

R W/m

2

/K

Mechanical power W ft-lbf/s W

Heat transfer W Btu/hr W

Enthalpy or kinetic energy J/kg Btu/lbm J/kg

Table 1-1 Units of Measure in GD Library

Quantity Metric unit English unit MKS unit

y

k

n

k

n

j

j

------------

=

Main Index

Gas Dynamics Library User Guide

Network Considerations

4

Three classes of components exist in the GD library: resistive, storage, and storage-resistive. Classes are

defined by the pressure P and flow rate w boundary conditions at the inlet and exits ports.

Specifically, the three classes of components are defined in the following table:

Since the inlet/exit boundary conditions in these classes are different, some connections between components

in the various classes cannot be made.

For example, two storage or two resistive components may not be connected. Compatible connection classes

include the following:

Storage/Resistive -> Storage/Resistive

Resistive -> Storage

Storage -> Resistive

Storage/Resistive -> Storage

Resistive -> Storage/Resistive

If two components do not connect completely via a default connection, it usually indicates that these

components have mismatched boundary conditions and cannot be connected directly. An example would be

trying to connect two resistive OR (orifice, resistive architecture) components in series. Since both

components require both upstream and downstream pressures to calculate flow rates, this connection is not

possible; an intervening “Storage” component with a pressure output, such as a NO (volume), would be

necessary.

Flowstream Identification—Ports

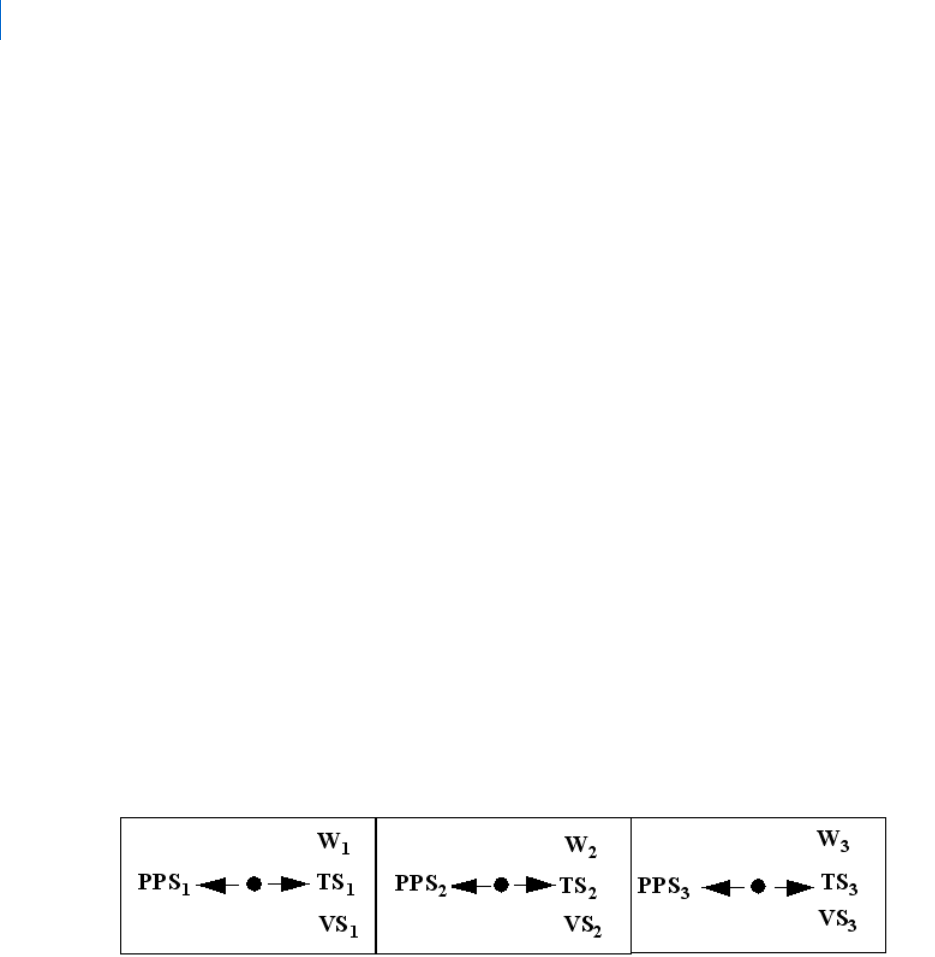

Each flowstream that enters or exits an GD library component is assigned a single-digit identifying number

called a port number. At each port, species partial pressures or species flow rates, gas temperature, and gas

kinetic energy are passed between connected components.

Figure 1. shows the ported inputs and outputs for a storage-resistive component with one inlet port and one

exit port.

Table 1-2 Gas Dynamics Library Component Classifications

Class at inlet at exit

Resistive P is input, w is output P is input, w is output

Storage P is output, w is input P is output, w is input

Storage/Resistive P is output, w is input P is input, w is output

R

S

S/ R

Main Index

5

Chapter 1: Overview

Network Considerations

Figure 1 Inputs and Outputs for Storage/Resistive GD Component Models

A positive value of flow at an inlet port indicates that flow is into the component, and a positive value of flow

at an exit port indicates flow from the component. Negatives flows are from the component at an inlet port

and to the component at an exit port. Temperature and kinetic energy are input and output at each port so

that bidirectional flow may be modeled.

The input boundary conditions for each fluid component in the gd library are the species partial pressure

vector at exit ports and the species flows at input ports. The output quantities for each fluid component in

the gd library are the species partial pressures at inlet ports and the species flows at exit ports. The inlet partial

pressures are almost always states, but the exit flows may be either states or variables. The inlet partial

pressures reflect the composition of the gas, while the species flow represents the total composition, including

(if any) water condensate flow.

Easy5 offers two ways for you to specify the connections between components:

1. DEFAULT option. This occurs when you select two connectible components, the “from”

component and the “to” component. Click on the “from” component with the left mouse button,

then click on the “to” component with the left mouse button. If a ported connection can be made

then it will happen automatically

Main Index

Gas Dynamics Library User Guide

Network Considerations

6

2. CUSTOM option. This occurs automatically if you left-click on two components which have no

compatible ported connection, or you can force it by right-clicking (instead of left-clicking) on the

“to” component. You can then select ports or individual connections in the Connectioni Properties

that appears.

The DEFAULT option will simultaneously connect all like-named quantities (e.g., T to T, P to P, W to W)

at connection interfaces. These options offer an efficient and systematic technique for model building. The

CUSTOM option supports specific connections between any output and any input.

When building an GD model and connecting to or from a component with more than 2 ports, the

DEFAULT connection option is not recommended. Rather, use the CUSTOM option to eliminate any

ambiguity about intended connections. For more information on how to make these connections, see

“Connecting Components” in the Easy5 User Guide.

Species Identification

Each GD model must contain one, and only one, GP component, which defines the gas species in the model.

The GP component, and each component that models fluid flow, has a component dimension “I” that is the

number gas species. The dimension “I” must be the same for each component before default ported

connections can be made. The vector parameter GAS in the GP component defines which gas species are

present, but not the amounts. The following gases are built into the GD library: air, nitrogen, oxygen, water,

hydrogen, carbon dioxide, carbon monoxide, sulfur dioxide, helium, methane, ethane, ethylene, propane,

argon, ammonia, hydrogen peroxide, krypton, xenon and neon.

As an example, to model a pneumatic system with air as the single gas species, one would set the dimension

“I” in the GP component and in each component that models fluid flow to 1, and set GAS_GP(1) to 1, which

is the gas identifier for air. To model a three-species gas containing nitrogen, oxygen and water vapor, set the

dimension “I” in the GP component and in each component that models fluid flow equal to 3, and set

GAS_GP(1) equal to 2 (nitrogen), GAS_GP(2) equal to 3 (oxygen) and GAS_GP(3) equal to 4 (water).

Position or order of species in the GSL vector is arbitrary, but once the GSL array is defined the partial

pressure vectors PP1(i) and PP2(i), and the species flows W1(i) and W2(i) are defined by this order. For this

three-species gas example, PP_Inlet(1) is the inlet partial pressure of nitrogen, and W_Exit(3) is the exit flow

of water.

Global Configurations

GD Library version 4.0 + takes advantage of the library global configuration features that were introduced

with Easy5 2015. For GD Library version 4.0.0, released with Easy5 2018, there is a global configuration

option to simplify the energy formulation for a model or submodel. By default, a GD library model can

model either dry gas or gas + liquid water (humidity condensation). You can choose to simplify the energy

formulation, and simply the Component Data Tables, by selecting Options > Set Model Global

Configurations, and selecting "Gas Phase only" for the Energy Formulation:

Main Index

7

Chapter 1: Overview

Network Considerations

This global configuration setting applies to all of the GD library components in the model, and results in a

simplified interface by removing unused quantities from some of the CDTs. These quantities are used only

when water/steam is present and when phase change is enabled, and otherwise clutter the interface. Some

performance improvement may also be noticed.

For example, component VY (Variable Volume), in the default configuration, has such inputs and states in

the default configuration:

Main Index

Gas Dynamics Library User Guide

Network Considerations

8

After changing the global Energy Formulation to "Gas Phase only" the same CDTs will be simplified:

Main Index

9

Chapter 1: Overview

Network Considerations

If you wish to change the configuration setting for a group of GD library components, but not all of the GD

components in a model, then put those components in a submodel, right-click on the submodel icon, and

select Set Submodel Global Configurations.

Main Index

Gas Dynamics Library User Guide

Network Considerations

10

Component Configurations

GD Library versions 3.0+ take advantage of library component features that were introduced with Easy5

version 7.0.0. Improvements in component library functionality allow for multiple configurations in a single

component with a different icons for each configuration, plus the ability to setup different classes of data,

define ports with unique names, force connections to specific ports, and enter conditional code for different

configurations. Thus it is possible to represent in a single library component the same functionality that

previously required several components.

For example, previous versions of the GD library contained four orifice components: OD (resistive, fixed

diameter), OR (storage/resistive, fixed diameter), OV (storage/resistive, variable area) and OW (resistive,

variable area).

Main Index

11

Chapter 1: Overview

Network Considerations

With Easy5 version 7.0 and above, and GD library version 3.0 all of these functionalities are contained within

a single component OR (OD, OW and OV have been placed in the Obsolete group):

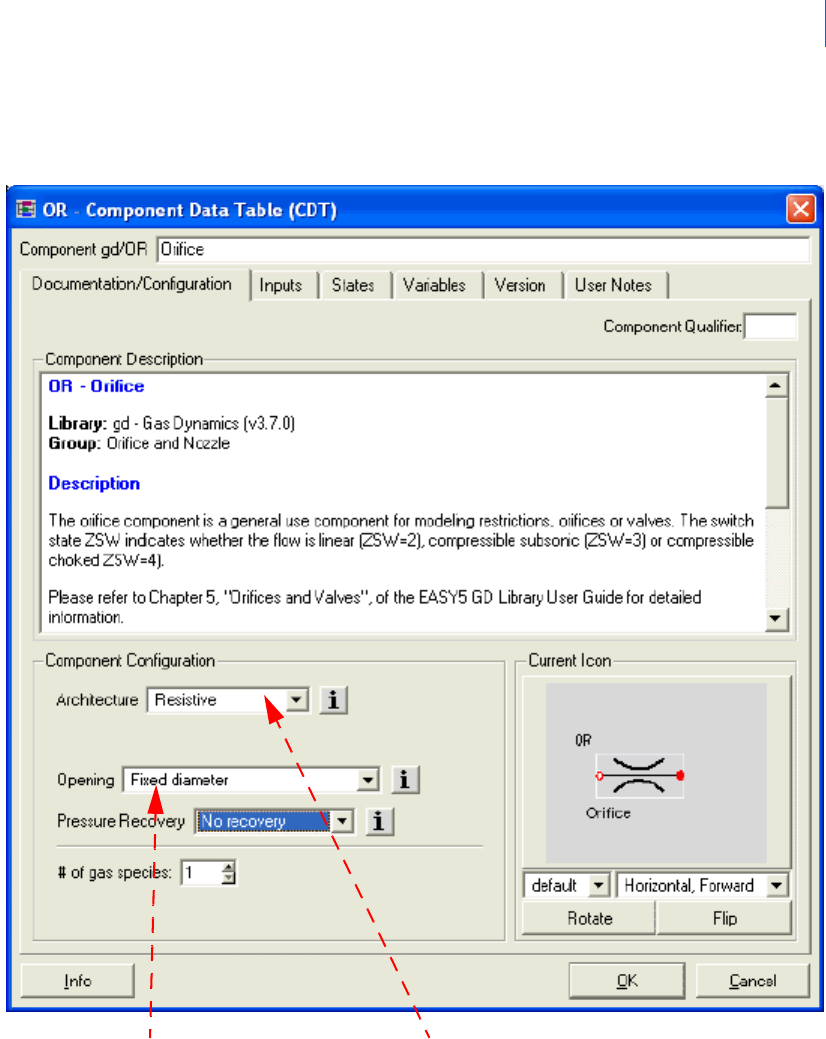

Figure 2 Selection Parameters in the OR-Orifice Component

Choose between Fixed

Diameter and Variable Area

Choose between Resistive

and Storage/Resistive Area

Main Index

Gas Dynamics Library User Guide

Network Considerations

12

The following types of configurations are common to many components in the GD library:

Architecture- The user may choose between Resistive and Storage/Resistive architectures for the OR orifice

and most valve components. Choosing the Storage/Resistive architecture activates pressure and temperature

states for upstream volume(s).

The user may choose between Storage and Storage/Resistive architectures for the volume components CS,

NO, VY. Choosing the Storage/Resistive configuration activates flow constraint states that must be

initialized, and requires the use of the RADAU54 integrator for simulation.

There are advantages to each type of architecture. Choosing Storage/Resistive architectures for all

components usually simplifies the model-building process, but the additional model states results in increased

CPU times and, for volume components, no choice of integrators- RADAU54 must be used. Choosing

Resistive (for valves and orifices) and Storage (for volumes) architectures may result in more time spent in

determining the optimal combinations of component configurations to connect, but the resulting model will

have a minimal number of states, often allow a choice of integrators, and run most efficiently. Experience has

shown that the extra investment of time that may required to build a model with a minimum number of states

will be returned in the form of decreased simulation run time, hence the default configuration for most

components is Storage (for volume components) or Resistive (for orifices, valves and flow resistances.

Formulation- All Storage and most Storage/Resistive components allow the user to select between Explicit and

Implicit formulations. (Storage/Resistive volumes always use the Implicit formulation). This allows the user

to choose between a formulation that allows either of the Gear algorithms to be used (Explicit) and a

formulation that is optimal for (and requires) RADAU54 (Implicit).

We recommend that the Explicit formulation be used, in conjunction with the BCS-Gear or Stiff Gear

algorithms, whenever possible. However, some circumstances require that RADAU54 be used:

Modeling chemical reactions with CR or ER

Modeling a compressor based upon polytropic efficiency with CP

Modeling laminar leakage from an actuator volume with LL

Using Storage/Resistive configurations of volume components such as CS, NO or VY

Coupling a GD library model with a mechanical motion model containing constraints

If it is necessary to use the RADAU54 integrator then we recommend that the Implicit formulation be used

for all components in the model, which will minimize the CPU time for simulations with this integrator, and

may make a difference between success or failure of the analysis. Models containing the transient momentum

pipe PC are particularly sensitive to formulation- simulations with RADAU54 have been observed to fail (due

to floating-point errors) when Explicitly formulated pipes are contained within the model.

The Explicit and Implicit formulations (when both are defined) are always physically identical, and differ

only in how the problem is numerically solved. For example, consider the mass and energy balances for an

ideal gas in an open, fixed volume with one inlet and one exit:

V

ρ

P

- V

ρ

T

-–

V– ρVc

p

P

·

T

·

w

1

w

2

–

max w

1

0,()c

p

T

F1

T–()k

F1

+[]min w

2

0,()c

p

T

R2

T–()k

R2

+[]q

·

+–

=

Main Index

13

Chapter 1: Overview

Component Types

This is a system of two equations and two unknowns ( and ), which in compact matrix notation can be

expressed as E = f(s, u, t) where E is the 2x2 matrix on the left-hand-side, is the 2x1 rate vector on the

left-hand-side, and f is 2x1 vector on the right-hand-side of the equation. For an explicitly formulated

component this equation is solved at each call to the model from the integrator: = E

-1

f.

An implicitly formulated component takes advantage of the capability of RADAU54 to directly integrate

equations of the form E = f(x, u, t). This conserves the CPU time, and avoids the possible numerical

difficulties associated with explicitly solving the matrix equations for . The syntax for doing this is described

in Chapter 13 of the Easy5 User Guide, “Implicit Modeling.” Examples of this syntax can also be found by

examining any of the GD library components (Library > Examine) that have the option of an implicit

formulation.

Component Types

Actuators

Double chamber linear actuator

Single chamber linear actuator

One-Dimensional Body Dynamics

Single moving mass with hard limits and friction

Two adjacent masses with hard limits and friction

Two interlocking masses with hard limits and friction

Two concentric masses with hard limits and friction

Boundary Conditions

Inlet orifice (pressure specified)

Inlet valve

Ram air inlet.

Boundary flow resistance

Tabulated mass flow parameter

Variable downstream: pressure and temperature specified

Variable upstream: pressure and temperature specified

Forces and body dynamics

Forces and/or volumes from dimensions and pressure

P

·

T

·

x

·

x

·

x

·

x

·

x

·

Main Index

Gas Dynamics Library User Guide

Component Types

14

Solenoid Force

Spring force

Spring stop

Sum of forces

Viscous damping

Compressor, Fan & Turbine

Compressor, based upon map of corrected flow

Compressor, based upon map of polytropic efficiency

Fan, based upon performance map

Simple shaft

Turbine, based upon map of corrected flow

Directional Control Valves

Five-way three position DCV

Four-way three position DCV

Three-way two position DCV

Heat Exchangers

Primary gas: single pressure state, discretized temperature array

Primary gas: discretized temperature and pressure vectors

Secondary gas: single pressure state, discretized temperature array

Secondary gas: discretized temperature and pressure vectors

Gas/gas heat exchanger: based upon efficiency map

Gas/liquid heat exchanger: based upon efficiency map

Minor Losses

Circular pipe bend

Converging branch

Diverging branch

Elliptical bend

Gradual contraction

Offset or compound bend

Rectangular bend

Main Index

15

Chapter 1: Overview

Component Types

Sudden contraction

Screen or grid

U-bend

Z-bend.

Miscellaneous

Filter

Gas properties

Additional gas makeup

Orifice area vs. position

PI Controller with hard limits

Pipe insulation with heat transfer to ambient

Rupture disk area

Water/gas separator.

Nodes and volumes

Cabin- with mass and energy sources/sinks.

Node- General purpose, can be configured as Storage or Storage/Resistive

Variable volume-can be configured as Storage or Storage/Resistive

Orifice and Nozzle

Converging-diverging nozzle

Fixed diameter orifice (resistive)

Fixed diameter orifice with upstream volume (storage/resistive)

Variable area orifice (resistive)

Variable area orifice with upstream volume (storage/resistive)

Pipes, lines and tubes

Discretized (finite difference) pipe with transient momentum and heat transfer

Method of characteristics pipe with transient momentum and heat transfer

Resistive pipe or annulus with heat transfer

Flow resistance based upon K-value or sDp vs. flow

Generalized flow resistance with multiple heat sources

Laminar leakage through an annulus

Main Index

Gas Dynamics Library User Guide

Equations of State in the Gas Dynamics Library

16

Sensors

Flow sensor

Pressure sensor

Temperature sensor

Thermal Analysis

Thermal node (diffusive or algebraic)

Thermal conductance (linear and/or radiation conductance)

Heat input summer

Pipe insulation with H.T. to ambient

Valves (each configurable as Resistive or Storage/Resistive)

Check valve- Includes simple and piloted operation.

Pressure regulating valve

Pressure relief valve with dynamic response

Simple Valve - Models the following types of valves: butterfly, gate and globe valves.

Equations of State in the Gas Dynamics Library

The equation of state that is used in the model is specified in component GP. If there is more than one gas

makeup then the equation of state can be specified for each gas makeup in the GM component(s).

The ideal gas option is the default, and will always result in the shortest simulations, hence we recommend

its use as long as it is physically realistic for your system. The gas density is given by

where ri is the species density, P

i

is the species (partial) pressure, M

i

is the species molecular weight, R is the

molar gas constant and T is the absolute temperature. The molar heat capacity, viscosity and thermal

conductivity are functions of temperature only, and correlated by cubic power series. A mixture heat capacity

is assumed to be a linear combination of the species heat capacities:

Important: Only one tabulated gas can be stored in memory during an analysis, so if there are

multiple gas makeups in your model then the option of a tabulated gas can be used in

only one of the gas makeups. If this equation of state option is specified for more than

one gas makeup, then it will only be applied to the make-up with the lowest index.

The Lee-Kestler equation of state will be used for the other tabular gases.

ρ

i

P

i

M

i

RT

-----------

=

Main Index

17

Chapter 1: Overview

Guidelines for Building and Analyzing GD Models

A mixture viscosity or thermal conductivity is calculated with the following mixing rule (3):

where

Guidelines for Building and Analyzing GD Models

Connecting Components

Always use the port option rather than the default when making fluid stream connections between

components with more than one inlet or exit port; otherwise, a default connection is all that is required.

Although a single connection line is displayed in the schematic between connected components, the line will

usually represent two to eight connected quantities. CLICK-M to examine the connection lines to verify all

expected connections have been made.

For bidirectional connections, bidirectional arrowheads are displayed as a default in the schematic. You can

modify the setup file for your Easy5 installation if you prefer single arrowheads. See Chapter 5 of the Easy5

User Guide for more details.

System Size

When developing a large model, usually the most efficient approach is to start small and expand. Develop

subsystem models first and find a steady-state operating point for each subsystem. Then merge and analyze

subsystems sequentially until the total system is developed. Use the Copy a Group utility to merge subsystem

models very efficiently.

Data Entry

You usually enter individual component data into a component’s on-screen data table. Component data

consists of tables, parameters, and initial conditions (for state variables). This data should represent the

primary database configuration for each component. Off-nominal data should not be entered into the

component data table but instead through temporary settings files or auxiliary input files specified at analysis

setup time.

C

p

y

i

C

pi,

i

=

μ

mix

y

i

μ

i

y

i

Φ

ij

j 1 n,=

--------------------------

i 1 n,=

=

Φ

ij

1

8

-------

1

M

i

M

j

------

+

12⁄–

1

μ

i

μ

j

----

12⁄

M

j

M

i

------

14⁄

+

2

=

Main Index

Gas Dynamics Library User Guide

Guidelines for Building and Analyzing GD Models

18

Error Controls

The GD library requires tight error controls in order to obtain physically realistic results. The following error

controls have been found to work in the models tested to date, and are the defaults for most of the GD library

components:

Occasionally, tighter error controls need to be used for a successful analysis. A convenient feature for

implementation of tighter error controls throughout a model is in the “General” tab of Analysis Settings

panel. There is a cell labeled “Multiply Error Controls (for continuous states) By”. All error controls for

continuous states are multiplied by this value (the default is 1). As an example, if a value of 0.1 is entered,

then all Error Controls for continuous states in the model will be tightened by a factor of 10.

There have also been instances where the error controls could be safely loosened with a significant decrease

in simulation CPU time, and the “Multiply Error Controls (for continuous states) By” feature may also be

used to loosen all the error controls in a model. However, we recommend that no error control for any

continuous state exceed 0.001, so caution should be used when taking advantage of this feature.

Model Operating Points

The operating point for an Easy5 model consists of numerical values for each state in your model (the state

vector), and the value of time (pertinent if your model includes time-dependent data). Easy5 allows you to

save operating points by user-specified filenames. These files can represent system steady-states at different

ambient conditions, model configurations, and others.

Load any operating point file into your model with the Options > Restore Operating Point menu. See the

section on auxiliary input files in the Easy5 Users Guide for other options to load model data.

Note: The Easy5 default value for some state variable initial conditions is not a good value for

pressures and temperatures. Initialize all primary state variables with as good an estimate as

you have.

Table 1-3 GD Library Error Control Defaults

State Error Control

Fluid Pressure 1.0e-07

Fluid Temperature 1.0e-08

Fluid Velocity 1.0e-06

Flow 1.0e-06

Switch States 1.0e-08

Most Other States 1.0e-06

Main Index

19

Chapter 1: Overview

Guidelines for Building and Analyzing GD Models

Steady-State Analysis

Systems modeled by the GD library are usually highly nonlinear. To find steady-state, Easy5 uses a modified

Newton-Raphson technique that uses the system Jacobian formed by a linearization of the nonlinear model.

The success of the steady-state operation for highly nonlinear systems can be very dependent on the user-

defined initial state vector.

Each valve and orifice component contains a switch-state that indicates the flow regime (molecular, viscous,

compressible or choked). Provision has been made for estimating these switch states during the calculation of

initial conditions. The estimates are based upon, and are exact for, perfect gas conditions. This estimation can

be enabled by setting the ICC parameter in the GP component to 1.

If your steady-state or transient analysis fails, execute a linear model generation analysis by selecting the

Analysis > Nonlinear > Linear Model Generation menu. This will print the Jacobian matrix and its

eigenvalues.

Examine the matrix and eigenvalues for unusual data, such as any of the following:

Extremely large numerical values. This could indicate poor scaling or an ill-posed system.

A row or column whose elements are all the same or nearly the same. This usually means the user has

included FORTRAN code that uses a local variable for memory or that calculated quantities are

being used before they are calculated or redefined.

Many eigenvalues with large positive real parts (usually indicates a model with incorrect connections

or bad data).

If a model contains actuator components (AC or AX) or mass dynamics components (PM or TM), it often

helps to find a steady-state with the position states frozen and save the resulting state vector. Use this saved

state vector as the initial operating point for a second steady-state analysis with one or more position states

activated, and repeat until a valid steady-state operating point is obtained.

Often some type of control action, that is, flow rate control, temperature control, or pressure control, is

included in a model. It is usually a good idea to first find steady-state for a subsystem with the controls frozen

and to save the resulting state vector. Then, using the saved state vector as the set of initial conditions for the

next steady-state, activate one controller and find steady-state, again saving the state vector. Repeat the

Note: The Easy5 Steady State solver will usually not work for the following types of models: 1)

models that include the Method of Characteristics (PX) pipe component, 2) models of

multispecies (variable composition) fluids. For these types of models you should simulate to

a steady-state condition using one of the stiff system integrators (Stiff Gear, BCS Gear or

RADAU54). When using a stiff system integrator as a steady-state solver you need to ensure

that all function generator have constant outputs that correspond to the initial time for

subsequent analysis.

Note: These results may not be relevant if your system has unreasonable initial condition values.

Main Index

Gas Dynamics Library User Guide

Guidelines for Building and Analyzing GD Models

20

sequence as you activate all controllers. Remember, proportional controllers have no states to freeze, but you

can set the proportional gain to zero to fix the valve position.

Occasionally you may find that a system that includes a controller with integral type control (zero steady-

state error) fails to converge and the resulting state vector is numerical nonsense. Your system as defined may

simply not have a steady-state solution at the set point or points you have requested. Relaxing the set point

or points may help.

If steady-state analyses persistently fail to converge, you can often obtain a better set of initial conditions by

performing a short simulation (with no forcing functions) and saving the state vector that exists at the end of

the simulation.

Another strategy for determining a steady-state operating point, applicable only for models that can handle

reverse flow (most GD and HC components) is to start with a trivial solution- a system at uniform

temperature and pressure and zero flow. Use steady-state analysis to then relax the boundary conditions to

the desired values and obtain the desired solution. Finally, it is important to realize that volumes with only

one input or one output, such as a blowdown tank, do not have a non-trival steady state. Often one will know

the initial conditions apriori, so that steady-state analysis is not necessary. If steady-state analysis is necessary

for such a system, then one must first freeze the pressure and temperature states for the blowdown tank.

References

1. A.H. Shapiro, The Dynamics and Thermodynamics of Compressible Fluid Flow, 1, Ronald (1953).

2. B.W. Andersen, The Analysis and Design of Pneumatic Systems, Wiley (1967).

3. R.B. Bird, W.E. Stewart and E.N. Lightfoot, Transport Phenomena, Wiley (1960).

Main Index

Chapter 2: Tutorial

MSC Nastran Implicit Nonlinear (SOL 600) User’s GuideGas Dynamics Library User Guide

2

Tutorial

Introduction 22

The Conceptual Model 22

Creating the Easy5 Block Diagram 22

Determining an Initial Operating Point 32

Simulating the System 35

Using Easy5 to Analyze a More Complex System 39

Main Index

Gas Dynamics Library User Guide

Introduction

22

Introduction

This tutorial is designed to familiarize you with some of the special considerations needed to model and

analyze gas flow with Easy5. Before beginning this tutorial, you should have installed Easy5 on your

computer and completed the tutorial section (Chapter 3, “Quick Tutorial”) in the Easy5 User Guide. You

should also have read Chapter 1: Overview of this user guide. It is assumed that you are already familiar with

the use of Easy5 to model and analyze simple systems.

The tutorial will guide you through the construction and analysis of a pneumatic system model. During this

process, several common mistakes that can be made will be pointed out. The tutorial may take two or three

hours to complete. We recommend that you set aside this time and work entirely through it. There are some

sections, marked lemmas, that illustrate important points but do not need to be completed to finish the

tutorial model.

The Conceptual Model

Pneumatic systems require some sort of power supply to do useful work. They may either require power input

(a compressor) or be statically charged with a reservoir of high pressure gas (such as a blowdown tank). For

the purposes of this example, you will select a blowdown tank as the power source. The system will be used

to power an actuator piston that is working against a load, in this case, pushing against a spring.

Such a system could be represented with the following schematic:

Figure 1 Tutorial System Schematic

Creating the Easy5 Block Diagram

An Easy5 block diagram is constructed by adding Easy5 components to an on-screen schematic, and

establishing data connections between these components. The following sections explain how to add and

connect components.

Main Index

23

Chapter 2: Tutorial

Creating the Easy5 Block Diagram

Adding Components

To begin your model of the blowdown tank subsystem, you will need some files stored by Easy5 in a special

directory for this tutorial. To retrieve these files, first enter the command you use to run Easy5 in a command-

shell and supply the option -demos, as shown in the following example:

Before starting the tutorial, you need to copy the tutorial files by either:

1. Typing the command

easy5x -demos at a command shell prompt, OR

2. Select Start > Program Files > Easy5 2021.3 > Demos >Copy Easy5 Demo Files in Windows.

3. Type in the option gd when prompted to enter the corresponding DirName.

Step Action

1 Start Easy5.

2 Enter a new model name called BlowdownTank when the opening menu displays.

3 Select the Add button.

4 When the Add Menu displays, scroll down the top section (Libraries) until the gd - Gas Dynamics

library displays.

5 Select the gd - Gas Dynamics library.

6 Select Nodes and Volumes from the Groups Menu.

7 Before dropping the component onto the schematic, add the qualifier, TN (for tank) to name the

component NOTN.

To do this, select the component from the bottom window of the Add window. The library and

component name display in the Add Component input field as gd/NO. Type in the qualifier TN

after NO.

8 Add NOTN to the schematic. Examine NOTN by pointing the cursor at the component and

either clicking the middle mouse button once or double-clicking the left mouse button. Click on

the Configuration tab if it is not active. Use the left pull down menu, under the icon, to change the

icon from Default to One Exit Port.

9 Add a variable area orifice. Select Orifices from the Groups Menu and add the OR-Orifice and set

the qualifier to TN. Place this component to the right of the NOTN component. Examine ORTN

and click on the Configuration tab if it is not active. Use the pull down menu to change the

Opening from Fixed Diameter to Variable Area, Internal Dynamics.

10 From the Pipes and Flow Resistances group, add the PC component with the qualifier BD (for

blow-down). Rotate the icon 270o by point the cursor at PCBD, right-click and hold, and select

Rotate from the popup menu.

Then repeat the last step, but select Flip instead of Rotate.

11 Add a GP-Gas Properties component from the Miscellaneous group. GD library models must

have one and only one GP component to identify global parameters, such as the gas species that are

present.

Main Index

Gas Dynamics Library User Guide

Creating the Easy5 Block Diagram

24

Easy5Your schematic should look like Figure 2.

Each component is identified by a title, such as Blowdown Tank, and a name, such as NOTN. You should

edit the title of each component to match the titles used in

Figure 2. Although this is not required, it helps to

document your model. To edit the title, select each component with a hold-right mouse button. Then select

Edit Title from the pop-up menu and edit the titles to match the titles used in this tutorial.

Figure 2 Initial Easy5 model without connections

If your component names do not match the names shown in

Figure 2, you should edit them as well. For

example, the NO Node component used in this model is named NOTN. The component name is a four-

character name using the two-character component identifier, NO, followed by a two-character

alphanumeric qualifier, “xx”. The qualifier is used to insure that each component has a unique name. Easy5

assigns the qualifier by default, although you can easily change it. To change it, highlight the component,

then press and hold the right mouse button. Select Open Data Table from the pop-up menu, select the

Documentation/Configuration and change the two-character qualifier as needed to match the component

names used in this tutorial.

Making Connections: Ports and Their Significance

The node component NOTN has at least 4 Inlet ports and 4 Exit ports. Inlets are characterized as connection

points where flow entering the component is positive, while at an Exit flow exiting a component is considered

as positive. Negative flows can be considered at any port. All Inlet ports are equivalent for component

NOTN, as are all Exit ports. However, this is not always true for other component in the GD library.

The port connection concept in Easy5 is very useful as it enables the communication of many items of fluid

information (flow rate, pressure, temperature, etc.) with a single action between adjacent components. (See

"

Network Considerations".)

Main Index

25

Chapter 2: Tutorial

Creating the Easy5 Block Diagram

To perform the default port connection between the NOTN and ORTN components, simply Click-R on

NOTN, then Click-R on ORTN. To specify a particular Inlet port or Exit port when connecting

components that have multiple Inlets and/or Exits, follow the steps below:

Step Action

1 Select the NOTN node component.

2 Right-click and hold with the cursor hovering over the ORTN component. Select Create Custom

Connection from the Component Connection Menu.

3 Select Exit2 under NOTN Source Ports

4 Select Inlet1 under ORTN Target Ports

5 Select OK. The connection is completed; it displays in the Port Connections field.

Main Index

Gas Dynamics Library User Guide

Creating the Easy5 Block Diagram

26

Figure 3 Port connection table.

Expand the connection by clicking on the + sign next to Exit2.

Figure 4 Expanded Connection Specification

This is an example of a bi-directional ported connection. The quantities W_Inlet1_ORTN,

WL_Inlet1_ORTN, TR_Inlet1_ORTN and KR_Inlet1_ORTN are passed from the orifice to the node, and

Main Index

27

Chapter 2: Tutorial

Creating the Easy5 Block Diagram

the quantities PP_Exit2_NOTN, TF_Exit2_NOTN, KF_Exit2_NOTN, and Q_Exit2_NOTN are passed

from the node to the orifice.

To continue the tutorial, make the following connections in your model, using the default connection

method. (See the Lemma on Default versus Port Connections)

The finished schematic should look similar to Figure 5.

Step Action

6 Connect ORTN to PCBD.

Lemma

Multiple Gas Species

Gas streams of variable composition may be modeled by setting the # of Gas Species in the

configuration tab of the component data table of GP, and in each fluid flow component, to the

appropriate number. The flow W is then a vector of species flows, and PP is a vector of species partial

pressures.

If multiple species are present, but the relative amounts do not change, then you can treat the gas as a

single species, as is commonly done for air.

Component GM - Additional Gas Make-ups is used to specify the gas species if there is more than

one gas make-up. For example, a model could be formulated with one stream containing air and

another stream containing pure nitrogen. There may be up to four GM components in a model, so that

five make-up streams (the first specified by the GP component) may be modeled.

Main Index

Gas Dynamics Library User Guide

Creating the Easy5 Block Diagram

28

Figure 5 Blowdown Model with Connections

Entering Data into the Model

Before you begin to enter data into your model, you will have to make a key decision that globally affects

your model; the system of units used, either SI or English. You will be using English units in this tutorial.

This information is entered into the GP component. Other data in the GP component is used to specify the

gas species that are present (but not the relative amounts), the ambient temperature, the pressure if not

otherwise specified, and other parameters.

You should first read Chapter 1: Overview of this user guide and the GP - Gas Properties component data

sheet for a more complete discussion of these parameters and of make-up indices before working on this part

of the tutorial.

Follow the steps below to enter more data and continue the tutorial:

Note: Any parameters or states that are not specified in the following section should be left at their

default values.

Main Index

29

Chapter 2: Tutorial

Creating the Easy5 Block Diagram

Step Action

1 Examine the GP - Gas Properties component; select it with a double click.

This opens the component data table. In the Documentation/Configuration tab there is a

Component Configuration called “# of gas species”. You will leave this setting in all components

at the default value of 1, indicating that the species pressures PP and the flows W are scalars

describing single gas species.

2 Enter the following data into the GP component. The input UN is used to select the unit system,

and GAS=1 defines the working gas to be dry air. TAM sets the ambient temperature to 86

o

F and

PAM defines the ambient pressure to be 14.7 psia. (Some other GD library components also have

inputs for local ambient conditions. The global ambient conditions set in component GP are used

when the local conditions have not been initialized.)

In Component For Parameter . . . Input the Value . . .

GP UN English

GAS 1

TAM 86

PAM 14.7

Main Index

Gas Dynamics Library User Guide

Creating the Easy5 Block Diagram

30

3 Change the names of some outputs in the model to be more mnemonic. You can change them by

examining the given component, double-clicking on the name to be replaced until it is completely

highlighted, and typing the new name.

Use the names given in the table below:

4 Since all user-defined names have been supplied, and the default component dimensions have been

accepted, you can now create an executable by selecting Build > Create Executable.

Step Action

For Component...

With the Easy5 Output Name .

. .

Type the New User-Defined

Name . . .

NOTN P1 (Secondary Variables) TankPressure

TF_Exit2 (Ported Variables) Tan kE xi tTem p

ORTN ACS (Primary States) OrificeArea

W_Exit2 (Primary Variables) Tan kE xi tFl ow

TS (Secondary Variables) OrificeStaticTemp

PS (Secondary Variables) OrificeStaticPressure

VS (Secondary Variables) OrificeVelocity

MCN (Secondary Variables) OrificeMachNumber

PCBD W_Exit (Primary Variables) PipeExitFlow

TF_Exit (Primary Variables) PipeExitTemp

P1 (Secondary Variables) PipeInletPressure

Note: If there were any tables in the model, they would need to be dimensioned

before creating the executable.

Main Index

31

Chapter 2: Tutorial

Creating the Easy5 Block Diagram

5 While that operation is continuing in the background, enter the rest of the parameter data for this

model:

Step Action

In Component . . . For Parameter . . . Type in the Value . . .

NOTN VOL (Primary Inputs) 1000

HI (Thermal Inputs) 10

HO (Thermal Inputs) 10

AHT (Thermal Inputs) 10

MTW (Thermal Inputs) 100

TAM (Thermal Inputs) 86

ORTN ARE (Primary Input) 0.01

TimeConstOpening 2

TimeConstClosing 2

CD (Primary Input) 0.8

PCBD LEN (Primary Input) 10

DH (Primary Input) 0.2

PP_Exit (Primary Input) 100

TR_Exit (Primary Input) 86

Main Index

Gas Dynamics Library User Guide

Determining an Initial Operating Point

32

Determining an Initial Operating Point

An initial operating point, or a set of “initial conditions,” can be determined in a number of ways:

By knowing, a priori, the initial condition values and simply making them known to Easy5.

By using Easy5’s Steady-State Analysis to solve for a set of initial condition values.

6 You need to initialize the pressure and state initial conditions — the starting values by entering the

following state initial conditions:

7 Enter “Blowdown System Example” in the Title field that appears when File > Properties ... is

selected.

8 Save the model (you can use the accelerator key Ctrl + S) to record the data you just entered.

Lemma

Multiple Gas Species

Gas streams of variable composition may be modeled by setting the # of Gas Species in the

configuration tab of the component data table of GP, and in each fluid flow component, to the

appropriate number. The flow W is then a vector of species flows, and PP is a vector of species partial

pressures.

If multiple species are present, but the relative amounts do not change, then you can treat the gas as a

single species, as is commonly done for air.

Component GM - Additional Gas Make-ups is used to specify the gas species if there is more than

one gas make-up. For example, a model could be formulated with one stream containing air and

another stream containing pure nitrogen. There may be up to four GM components in a model, so that

five make-up streams (the first specified by the GP component) may be modeled

Step Action

In Component . . . For State . . . Type in the Value . . .

NOTN

PP_Inlet

500

PP_Inlet

86

TW

86

PCBD

PPS

100

TS

86

VS

0

TW_Wall

86

Main Index

33

Chapter 2: Tutorial

Determining an Initial Operating Point

By calculating our own initial condition values using a customized Code component with special

code and the Initial Condition analysis.

By integrating to steady-state using a Simulation analysis.

In this example you’re going to use Easy5’s Steady-State Analysis to locate a set of initial conditions for us.

The gd library presents some difficult problems for finding steady-state operating points. The differential

equations in pressure and temperature are coupled and nonlinear. Therefore, you may have to take some

special measures to find a stable operating point. These techniques are shown as “hints” in this section.

The GP component contains a parameter ICC that is, by default, initially set to zero. If this value is set to

unity, special code will be executed during the initial condition calculation (Calc-XIC) that precedes all

analyses, including steady-state analysis, to estimate the flow indicator switch states in all orifice and valve

throats.

This steady-state estimate, which is exact for perfect gases, is based upon the upstream and downstream