GENERAL SUSPENSION

FORK MANUAL

Overvi ew………………………………………………………………………………………….……….2

Important safety information…………………………..…………………………….…………2

Before every ride…………….…………………………………………………………………………3

Fork assembly……………….………………………………………………………………..……..….3

Tire clearance test……………………………………………………………………………………4

Tire clearance……………….…………………………………………………………………………..4

Suggested tire size……………………………………………………………………………….…5-6

Maximum brake rotor size…………………………………………………………………………7

15AH2/12AH2 bolted thru axle assembly…………………………………………………8

20mm bolted thru axle assembly…….…………………………………..……………………9

20mm cross thru axle assembly…………………………………………………………………9

Q-LOC assembly………………….…………………………………………………………………10

Setting SAG…………………………………………………………………………………………….11

Air pressure adjust…….…………………………………………………………………………12

Air volume adjust………….…………………………………………………………………………13

Coil spring prel oad….…………………..………………………….………………..………….…14

Maintenance of the fork………………..............……………………………………………14

Intended use……..……………….......................………………………………………………15

ENGLISH

Carefully read, understand and follow the instructions provided in this

manual, and keep it in a safe place for future reference. If you have any

doubt whatsoever regarding the use or maintenance of any SR

SUNTOUR product, please contact SR SUNTOUR. Failure to follow these

warnings and instructions can result in product malfunction, causing an

accident, severe injury or death.

WARNING !

We have language options for CN, DE, EN, ES, FR, IT, JP & NL on our

website. Please navigate to:

www.srsuntour-cycling.com > Service > Download area > Consumer

Downloads > Bike > Owners manuals > General Fork Manual

Failure to follow all warnings and safety instructions can cause your product to malfunction,

resulting in an accident, severe personal injuries or even death to the rider.

WARNING !

Ø Read this manual thoroughly before using your

suspension system.

Ø These instructions contain important information about

the correct installation, service and maintenance of your

suspension fork. Common mechanical knowledge may

not be sufficient. Your suspension fork should only be

installed, serviced and/or maintained by a trained and

qualified bicycle mechanic with specialized tools.

Ø Our suspension systems contain fluids and gases under

extreme pressure. Never try to open any SR SUNTOUR

suspension system! Pieces can be violently ejected.

Ø SR SUNTOUR suspension forks are designed as a single

integrated system. To avoid product malfunction and an

accident, use only genuine SR SUNTOUR spare parts. The

use of third-party supplier spare parts also voids the

warranty of your suspension system.

Ø Your suspension fork is not intended for jumps,

aggressive downhill rides, freeride or dirt jumping if the

warning sticker on your suspension system prohibits

these activities. Disregarding these instructions may

cause your suspension fork to fail, resulting in an

accident, personal injury or death, and will void the

warranty.

Ø SR SUNTOUR suspension fork is designed for use by a

single rider.

Ø Select the correct suspension fork according to your

frame’s dimensions and your personal riding style.

Installing a suspension fork which does not match the

geometry of your frame could result into a failure of the

suspension fork or frame itself, and will void the shocks

warranty.

failure of the suspension fork or frame itself, and

will void the shocks warranty.

Ø Know the limits of your skill and experience, and never

ride beyond them.

Ø Read, understand and follow all owner’s manuals

provided with your bike and all of its components.

Ø Always be equipped with proper safety gear. This

includes a properly fitted and fastened helmet.

According to your riding style you should use additional

safety protection. Make sure your equipment is in

flawless condition.

Ø Even if you had a suspension system in the past, ride

carefully and slowly to become accustomed to the feel of

your new suspension fork.

Ø SR SUNTOUR suspension forks are not equipped with

front reflectors for use on public roads. If you intend to

use your bicycle on public roads or bicycle paths, you

must install the required front reflectors. Please contact

your dealer.

Ø If you are using a bicycle rack that requires the front

wheel to be removed, carefully insert and remove the

dropouts from the bike rack. Do not bend the dropouts !

Ø If you are using a bicycle rack that fastens the bicycle at

the front dropouts only, then the rear wheel must be

securely fastened to prevent movement of the rear

wheel. Movement of the rear wheel will damage the

front dropouts, and this damage may not be visible to

you.

Ø If the bicycle has fallen off the bicycle rack, have it

inspected by a qualified bicycle mechanic before riding it

again.

2

Disc brake mount

For more

information check

page 7

Disc

brake

mount

PM 8”

IMPORTANT SAFETY INFORMATION

OVERVIEW

BEFORE EVERY RIDE

Avoid serious personal injury or even death. Do not ride the bicycle if any of the following

criteria is not met! Correct any condition before you ride.

WARNING !

Ø Inspect your bicycle and suspension system including

the handlebars, pedals, crank arms, seat post, saddle,

etc. for any cracks, dents, bent or tarnished parts. Also

search for any oil leaking out of your shocks. Be sure to

check hidden areas on the underside of your bike. If any

condition exists, consult a trained and qualified bicycle

mechanic to determine the cause and make any

necessary correction.

Ø Compress your suspension system with your body

weight. If it feels too soft, make the necessary

adjustments until you have reached the correct SAG

value. Please also see the instruction in this manual

regarding SAG.

Ø Make sure your brakes are properly installed/adjusted

and work correctly.

Ø Spin the wheels. Make sure that wheels are perfectly

centered and do not contact the suspension fork or

brakes.

Ø If you are using a quick release system to fasten your

wheel set, make sure that all levers and nuts are

properly tightened. In case you are using a through axle

system, make sure that all fixing bolts are tightened with

the appropriate torque values. Strictly follow the

instructions provided by the manufacturer of the quick

release or through axle system.

Ø Check the cable length and routing of your components.

Make sure they do not interfere with your steering of

the bicycle.

Ø If you are using reflectors for on-road cycling, make sure

they are clean and properly installed.

Ø Check mounting hardware of all components to make

sure everything is tightened.

Ø Bounce your bike on the ground while looking and

listening for anything which might be loose.

FORK ASSEMBLY

Avoid product malfunction, an accident, personal injury or death. Your new SR SUNTOUR

suspension fork should be installed, maintained and serviced by a qualified and trained bicycle

mechanic. Avoid product failure and an accident, personal injury or death. All mounting screws

must be tightened with the respective torques specified by the manufacturer of each individual

component (i.e., brake, headset, etc.).

WARNING !

1. Remove the old fork from your bicycle. Remove the headset crown race from the fork.

2. Measure the length of the steerer tube of your old fork and compare it to the length of the steerer tube of the SR

SUNTOUR fork. The standard length of SR SUNTOUR suspension fork steerer tube is 255mm. It may be necessary

to shorten the steerer tube to the correct length.

3. Install the fork crown race firmly at the top of your fork crown. Reattach the fork assembly (headset, spacer,

handlebar stem) to the bicycle. Adjust the headset until no more play is observed. Further information can be

found in the installation instructions of the headset manufacturer.

You can use the following formula to determine the proper length of the steerer tube: Head tube of the frame

+ Headset height + Spacer if applicable + Height of the stem - 3 mm distance = Length of the steerer tube

4. Install and properly adjust the brakes according to the brake manufacturer’s instructions. If you are using a disc

brake, install the brake only into the designated threaded receptacle hole for the disc brake. Use only cantilever

brakes that are made for use without reinforcing brace. Follow the assembly instructions of your brake

manufacturer. Select the proper length for the brake cable so that it does not interfere with the fork or steering.

5. Reattach the front wheel. Make sure that all clamping levers and nuts are set and tightened properly (at least

four threads must engage in the adjusting nut when the quick release is locked). If the fork is equipped with a

thru-axle system, then all screws must be checked for proper torque. Follow the instructions of the Quick

Release or Turn-Axle manufacturer.

3

4

TIRE CLEARANCE TEST

1. Depressurize the fork. (if equipped with air suspension)

2. Compress the fork all the way.

3. Measure the distance between the top of your tire and the underside of the fork crown. The distance

must not be less than 10 mm! If the tire is too big, it will touch the underside of the crown when the

fork is fully compressed.

4. Relieve the fork and pump it up again if it is an air fork.

5. Take into account that the gap is reduced if you are using a fender! Repeat the “tire clearance test” to

ensure that the distance is sufficient. You must repeat this test every time you change your tires to

another size!

TIRE CLEARANCE

Below dimensions are based on the bottom case type. Some numbers are referred based on the bottom

case type which have fender mount interface, and some are without. Please check in advance whether the

wheel and fork are compatible. The necessary information can be found on the side of the tire. Every tire

has a different external diameter (width and height of the tire). For this reason, check the distance

between your tire and the fork to make sure your tire does not touch the fork under any circumstances.

Bear in mind that the narrowest part of the fork is at the brake boss level. If you want to remove your

wheel, you must release the air from your tire, among other things, in order to fit it through the brake boss

level.

Using a tire that is larger than the maximum tire size allowed for your fork is very dangerous

and can cause accidents, serious injuries and even death. Inadequate tire clearance will result

in sudden and unexpected loss of bicycle control, an accident, personal injury or death.

WARNING !

5

SUGGESTED TIRE SIZE

Fork model

Stanchion

size

Suggested tire

size

Max tire width

Max. tire outer diameter

(O.D.)

(* Note below)

RUX38 29" BT

38mm 29" x 2.8" 73mm 770mm

RUX38 27.5" BT

38mm 27.5" x 2.8" 73mm 732mm

DUROLUX38 29" BT

38mm

29" x 2.6" /

27.5" x 2.8"

63mm 756mm

DUROLUX36 29" BT

36mm

29" x 2.6" /

27.5" x 2.8"

63mm 756mm

DUROLUX36 27.5" BT

36mm 27.5" x 2.6" 63mm 723mm

AURON35 29" BT

35mm

29" x 2.4" /

27.5" x 2.8"

63mm 756mm

AURON35 27.5" BT

35mm 27.5" x 2.8" 73mm 737mm

AURON34 29"

34mm 29" x 2.25" 58mm 752mm

AURON34 27.5"

34mm 27.5" x 2.25" 58mm 708mm

AION35 29" BT

35mm

29" x 2.4" /

27.5" x 2.8"

63mm 756mm

AION35 27.5" BT

35mm 27.5" x 2.8" 73mm 737mm

AION34 29"

34mm 29" x 2.25" 58mm 752mm

AION34 27.5"

34mm 27.5" x 2.25" 58mm 708mm

ZERON35 29" BT

35mm

29" x 2.4" /

27.5" x 2.8"

63mm 756mm

ZERON35 27.5" BT

35mm 27.5" x 2.8" 73mm 737mm

AXON34

-werx 29" BT 34mm 29" x 2.4" 63mm 756mm

AXON34

-elite 29" BT 34mm 29" x 2.4" 63mm 756mm

AXON34 29" BT

34mm 29" x 2.4" 63mm 760mm

AXON34 27.5" BT

34mm 27.5" x 2.6" 67mm 725mm

AXON32 29" BT

32mm 29" x 2.4" 63mm 756mm

AXON32 27.5" BT

32mm 27.5" x 2.5" 66mm 724mm

AXON32 29"

32mm 29" x 2.25" 58mm 754mm

AXON32 27.5"

32mm 27.5" x 2.25" 58mm 710mm

EPIXON 29"

32mm 29" x 2.25" 58mm 754mm

EPIXON 27.5"

32mm 27.5" x 2.25" 58mm 710mm

EPIXON 26"

32mm 26" x 2.25" 58mm 684mm

RAIDON34 29" BT

34mm 29" x 2.4" 63mm 760mm

RAIDON34 27.5" BT

34mm 27.5" x 2.6" 67mm 725mm

RAIDON32 29" BT

32mm 29" x 2.4" 63mm 756mm

RAIDON32 27.5" BT

32mm 27.5" x 2.5" 66mm 724mm

RAIDON32 29"

32mm 29" x 2.25" 58mm 754mm

RAIDON32 27.5"

32mm 27.5" x 2.25" 58mm 710mm

RAIDON32 26"

32mm 26" x 2.25" 58mm 684mm

XCR34 29" BT

34mm 29" x 2.4" 63mm 760mm

XCR34 27.5" BT

34mm 27.5" x 2.6" 67mm 725mm

XCR32 29" BT

32mm 29" x 2.4" 63mm 756mm

XCR32 27.5" BT

32mm 27.5" x 2.5" 66mm 724mm

XCR32 29"

32mm 29" x 2.25" 58mm 754mm

XCR32 27.5"

32mm 27.5" x 2.25" 58mm 710mm

XCR32 26"

32mm 26" x 2.25" 58mm 684mm

XCR 24"

32mm 24" x 2.1" 54mm 624mm

6

XCM34 29 BT

34mm 29" x 2.4" 63mm 756mm

XCM34 27.5 BT

34mm 27.5" x 3.0" 78mm 740mm

XCM32 29" BT

32mm 29" x 2.4" 63mm 752mm

XCM32 27.5" BT

32mm 27.5" x 2.6" 67mm 730mm

XCM 24" BT

30mm 24" x 2.8" 73mm 678mm

XCM 29"

30mm 29" x 2.4" 63mm 758mm

XCM 27.5"

30mm 27.5" x 2.25" 58mm 714mm

XCM 26"

30mm 26" x 2.25" 58mm 688mm

XCM

-JR. 20" 28mm 20" x 2.1" 56mm 526mm

XCT30 29"

30mm 29" x 2.25" 58mm 750mm

XCT30 27.5"

30mm 27.5" x 2.25" 58mm 714mm

XCT L24"

28mm 24" x 2.1" 54mm 628mm

XCT 20” plus

28mm 20" x 2.8" 73mm 554mm

XCT L20"

28mm 20" x 2.1" 56mm 526mm

XCT 24"

25.4mm 24" x 2.1" 54mm 628mm

XCT 20"

25.4mm 20" x 2.1" 56mm 526mm

XCE28 29"

28mm 29" x 2.25" 58mm 750mm

XCE28 27.5"

28mm 27.5" x 2.25" 58mm 714mm

XCE28 26"

28mm 26" x 2.1" 54mm 680mm

MOBIE34 700C

34mm 700C x 57C 62mm 753mm

MOBIE34 27.5"

34mm 27.5" x 2.4" 63mm 717mm

MOBIE45 700C

34mm 700C x 57C 59mm 751mm

MOBIE45 27.5"

34mm 27.5" x 2.4" 63mm 717mm

MOBIE25 700C

32mm 700C x 57C 59mm 751mm

MOBIE25 27.5"

32mm 27.5" x 2.4" 63mm 717mm

MOBIE

-A32 29" 32mm 29" x 2.4" 63mm 760mm

MOBIE

-A32 27.5" 32mm 27.5" x 2.4" 63mm 717mm

MOBIE

-A32 20" CRG 32mm 20" x 2.25" 58mm 530mm

XCT

-ATB 29" 28mm 29" x 2.4" 63mm 760mm

XCT

-ATB 27.5" 28mm 27.5" x 2.4" 63mm 724mm

GVX32

-15 700C 32mm 700C x 45C 50mm 722mm

NRX32

-15 700C 32mm 700C x 48C 50mm 722mm

NRX30 700C

30mm 700C x 48C 50mm 722mm

NVX30 29"

30mm 29" x 2.4" 63mm 760mm

NVX30 27.5"

30mm 27.5" x 2.4" 63mm 717mm

NCX30 700C

30mm 700C x 48C 50mm 722mm

TR

-HSi 700C 30mm 700C x 52C 54mm 738mm

NEX

-E25 700C 30mm 700C x 52C 54mm 738mm

NEX

-E25 26" 30mm 26" x 2.1" 54mm 678mm

NEX 700C

28mm 700C x 48C 50mm 738mm

NEX 26"

28mm 26" x 2.1" 54mm 678mm

M3010

-700C 25.4mm 700C x 52C 54mm 742mm

M3010

-26" 25.4mm 26" x 2.1" 54mm 684mm

M3010

-24" 25.4mm 24" x 2.1" 54mm 630mm

M3010

-20" 25.4mm 20" x 2.1" 56mm 526mm

CR85

-E25 700C 30mm 700C x 48C 50mm 722mm

CR85

-E25 26" 30mm 26" x 2.1" 54mm 684mm

CR8 700C

28mm 700C x 48C 50mm 722mm

CR8 26"

28mm 26" x 2.1" 54mm 684mm

CR7 700C

25.4mm 700C x 48C 50mm 722mm

CR7 26"

25.4mm 26" x 2.1" 54mm 684mm

* Note: Some of above dimensions are referred based on "with fender", and some are without. Please check the

specification sheet for more details.

7

MAXIMUM BRAKE ROTOR SIZE

Fork model Stanchion size

Rotor size when disc

caliper mounted directly

Max. rotor size

RUX38 29" BT

38mm 203mm 203mm

RUX38 27.5" BT

38mm 203mm 203mm

DUROLUX38 29" BT

38mm 203mm 220mm

DUROLUX36 29 BT

36mm 180mm 220mm

AURON35 29"/27.5" BT

35mm 180mm 203mm

AURON34 29"/27.5"

34mm 160mm 203mm

AION35 29"/27.5" BT

35mm 180mm 203mm

AION34 29"/27.5"

34mm 160mm 203mm

ZERON35 29"/27.5" BT

35mm 180mm 203mm

AXON34

-werx 29" BT 34mm 160mm 180mm

AXON34 29"/27.5" BT

34mm 180mm 203mm

AXON32 29"/27.5" BT

32mm 160mm 180mm

AXON32 29"/27.5"

32mm 160mm 180mm

EPIXON 29"/27.5"/26"

32mm 160mm 180mm

RAIDON34 29"/27.5" BT

34mm 180mm 203mm

RAIDON32 29"/27.5" BT

32mm 160mm 180mm

RAIDON32 29"/27.5"/26"

32mm 160mm 180mm

XCR34 29"/27.5" BT

34mm 180mm 203mm

XCR32 29"/27.5" BT

32mm 160mm 180mm

XCR32 29"/27.5"/26"

32mm 160mm 180mm

XCR 24"

32mm 160mm 180mm

XCM34 29"/27.5" BT

34mm 160mm 203mm

XCM32 29"/27.5" BT

32mm 160mm 180mm

XCM30 29"/27.5"/26"

30mm 160mm 180mm

XCM 24" BT

30mm 160mm 180mm

XCM

-JR. 20" 30mm 160mm 180mm

XCT30 29"/27.5"

30mm 160mm 180mm

XCT28 L24"

28mm 160mm 180mm

XCT 20” plus

30mm 160mm 180mm

XCT L20"

30mm 160mm 180mm

XCT 24"/20"

25.4mm 160mm 180mm

XCE28 29"/27.5"/26"

28mm 160mm 180mm

Mobie45 700C/27.5"

34mm 160mm 203mm

MOBIE34 700C/27.5"

34mm 180mm 203mm

Mobie25 700C/27.5"

32mm 160mm 180mm

Mobie

-A32 29"/27.5" 32mm 160mm 180mm

MOBIE

-A32 20" CRG 32mm 160mm 180mm

XCT

-ATB 29"/27.5" 28mm 160mm 180mm

GVX32

-15 700C 32mm 160mm 180mm

NRX32

-15 700C 32mm 160mm 180mm

NRX30 700C

30mm 160mm 180mm

NVX30 29"/27.5"

30mm 160mm 180mm

NCX30 700C

30mm 160mm 180mm

NCX28 26"

28mm 160mm 180mm

NEX

-E25 700C 30mm 160mm 180mm

NEX 700C/26"

28mm 160mm 180mm

M

-series 25.4mm 160mm 180mm

8

15AH2/12AH2 BOLTED THRU AXLE ASSEMBLY

Note: Before installation, make sure to check the o-ring is correctly seated at the thread part.

1. Fully insert the axle on the

drive-side.

2. Tighten the axle with a

6mm Allen wrench by the

suggested tightening

torque of 8-10Nm.

3. Check the axle’s thread. It

must be visible.

1. Loosen the axle on the

drive side with a 6mm.

2. Pull out the axle.

9

20MM BOLTED THRU AXLE ASSEMBLY

1. Slide in the axle and tighten

it with a 6mm Allen wrench

by suggested tightening

torque of 10Nm.

2. Tighten the safety clamp

with a 4mm Allen wrench

by suggested tightening

torque of 7Nm.

20MM CROSS THRU AXLE ASSEMBLY

1. Slide in the axle

on the quick-lock

side.

2. Tighten the axle

with the red

lever.

3. It is possible to

slide the lever

into the axle now.

4. Lock the quick

release.

5. Set the

tensioning force

with a 4 mm

Allen wrench if

needed.

6. The lever should

be flush to the

bottom case.

10

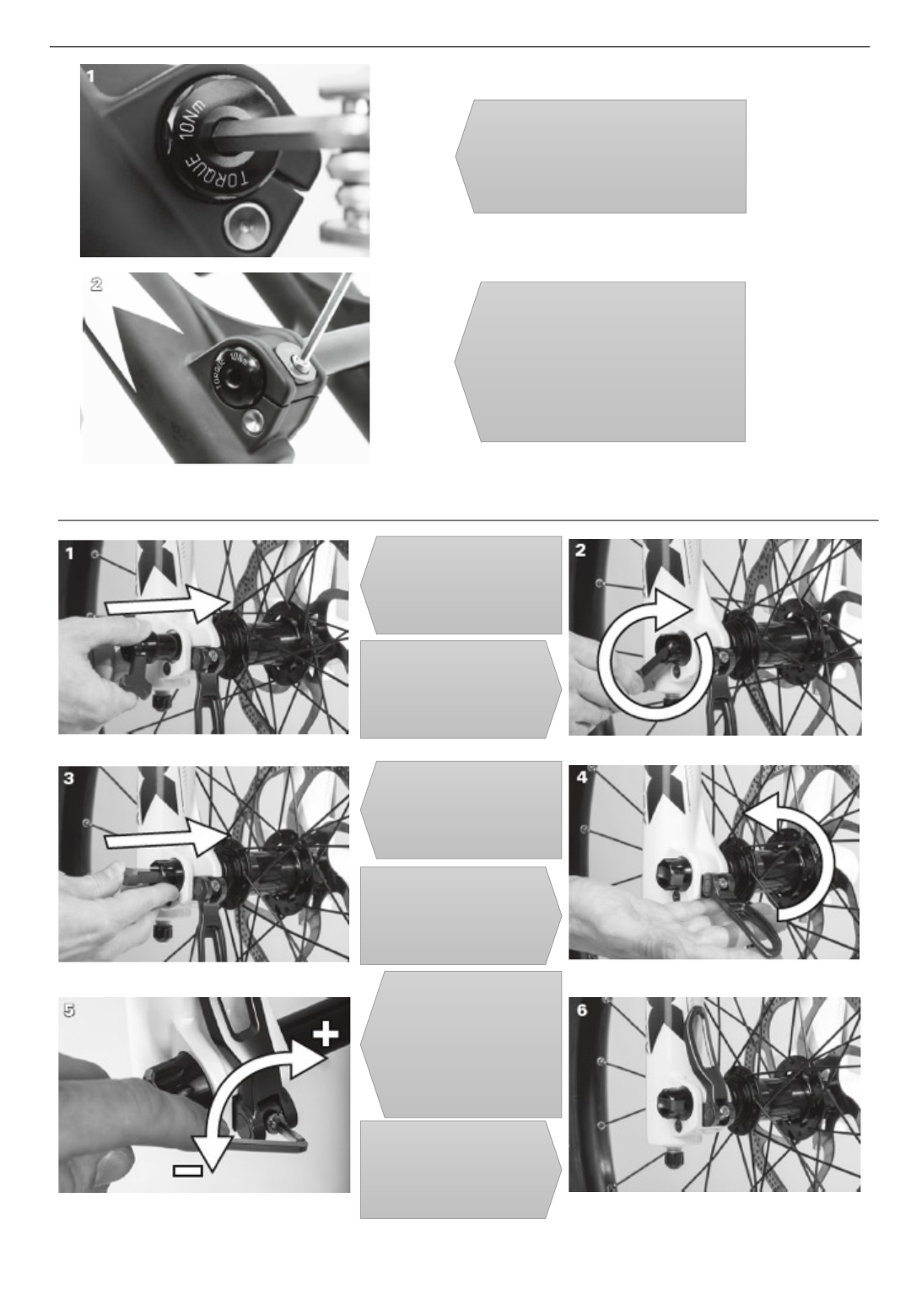

Q-LOC ASSEMBLY

1. Check the

segmented flange

to be expanded

before

installation and

open the lever

completely.

2. Slide in the axle

until it "clicks".

Make sure the

segmented flange

is expanded.

1. Open the lever

completely.

2. Press adjust nut

until segmented

flange retracts.

3. Open the lever

completely. Turn

nut clockwise

until flange stays

latched.

4. Pull out the axle.

3. Set the tension of

the nut until the

flange is flush

with the dropout.

4. Close the lever

completely.

Check if it’s firmly

seated. Re-

tighten the nut if

necessary.

11

SETTING “SAG”

To achieve the best performance from your SR SUNTOUR suspension air spring forks, adjust the air

pressure to attain your proper sag setting. Sag is the amount your suspension compresses under your

weight and riding gear and luggage. Sag range should be set of total fork travel. Make sure to set sag with

the compression knob in the OPEN position.

Ø Below chart is the suggested SAG range and the original air pressure chart, set for the SR SUNTOUR air

suspension forks from the factory. Remember that these are the starting points. Adjustments will vary

based on rider ability, trail conditions, frame design, and personal preference. After setting up your

suspension fork, check your sag to make sure that you are within the recommended SAG settings.

Ø The SAG is the compression which is caused by the rider’s weight including equipment (such as

backpack), seating position and the frame’s geometry and not as a result of riding. Every rider has a

different weight and seating position. Therefore the front fork will sag more or less. To assure a proper

function of suspension front fork and not to interfere its performance, setting a proper SAG is the

important way to find the correct air pressure for your air suspension fork.

Fork travel SAG (%) SAG (mm)

200 - 180mm 30 - 35% 70 - 54mm

180 - 160mm 25 - 30% 54 - 40mm

160 - 140mm 20 - 25% 40 - 28mm

140 - 120mm 20 - 25% 35 - 24mm

120 - 100mm 15 - 20% 24 - 15mm

100 - 80mm 15 - 20% 20 - 12mm

80 - 63mm 10 - 15% 12 - 6mm

Setting tip for EQ air forks

Ø Step 1: Put the suggested air pressure and compress the fork at least 50% of full travel several times in

order to equalize the air pressure between positive and negative air chamber.

Ø Step 2: Sit on the bike with equipment (such as backpack) and ask somebody holding the bike, stand on

the pedals, and the compress the fork several times. Then sit on your bike at your normal riding

position.

Ø Step 3: Slide the SAG indicator O-ring down to the top of the dust seal.

Ø Step 4: Gently step off the bike without compressing the fork furthermore.

Ø Step 5: Check the O-ring position to see if the SAG setting is properly done.

Ø Step 6: In case if the SAG setting is not properly done, air pressure must be adjusted.

• In order to increase the SAG, decrease the air pressure.

• In order to decrease the SAG, increase the air pressure.

ü Repeat the above procedure until you can find the correct SAG setting.

12

AIR PRESSURE ADJUST

The suggested settings in this manual are designed to be a starting point, in order to get you on

your first ride in as simple as possible. For more details, consult a qualified and trained bicycle

mechanic at your bike shop to get proper advice.

As you ride and getting used to your fork, adjust the settings as needed.

WARNING !

Rider weight

(kg)

Suggested air pressure (psi)

<EQ air system forks>

RUX38 / DUROLUX38

DUROLUX36 / AURON35

AXON34-werx

< 55 < 40 35 - 50 40 - 55

55 - 65 40 - 50 50 - 60 55 - 65

65 - 75 50 - 60 60 - 70 65 - 75

75 - 85 60 - 70 70 - 85 75 - 85

85 - 95 70 - 85 85 - 105 85 - 100

95 < 85 + 105 + 100 +

Air pressure (factory setting) 70psi 90psi 95psi

Max. pressure 105psi 120psi 145psi

Rider

weight

(kg)

Suggested air pressure (psi)

<Air system forks>

AION35

ZERON35

AXON34

RAIDON34

XCR34

-

air

AXON32

EPIXON32

RAIDON32

XCR32

-

air

XCR 24"

air

XCM

-Jr.

-

air

MOBIE34-

air

MOBIE45-

air

Mobie25-

air

GVX32

-

air

NRX-air NCX-air

< 55 35 - 50 40 - 55 40 - 55 40 - 55 40 - 55 35 - 50 40 - 55 40 - 55 40 - 55 40 - 55

55 - 65 50 - 60 55 - 65 55 - 65 50 - 60 55 - 65 55 - 65 55 - 65 55 - 65

65 - 75 60 - 70 65 - 75 65 - 75 60 - 70 65 - 75 65 - 75 65 - 75 65 - 75

75 - 85 70 - 85 75 - 85 75 - 85 70 - 85 75 - 85 75 - 85 75 - 85 75 - 85

85 - 95

85

-

105

85

-

100

85

-

100

85

-

105

85

-

100

85

-

100

85

-

100

85

-

100

95 < 105 + 100 + 100 + 105 + 100 + 100 + 100 + 100 +

Air

pressure

(factory

setting)

90psi 95psi 110psi 50psi 50psi 90psi 100psi 85psi 85psi 80psi

Max.

pressure

120psi 145psi 145psi 100psi 100psi 120psi 130psi 120psi 120psi 120psi

Note:

Above numbers are reference only. Correct air pressure must be adjusted

by individual rider while checking

the sag.

13

AIR VOLUME ADJUST

Additional tuning options: Air Volume Adjust Spacers

Changing air volume spacers in some fork models is an easy internal adjustment that allows you to change

the amount of mid stroke and bottom out resistance.

Even if you have set your sag, but using full travel (bottoming out) too easily, then you could install one or

more spacers to increase bottom out resistance.

Even if you have set your sag, but still not using full travel, then you could remove one or more spacers to

decrease bottom out resistance.

Installation procedure and tuning options can be suggested as below chart.

EQ air system forks

Number of Air volume spacers (rubber clip type)

RUX38 DUROLUX38 DUROLUX36 AURON35 AXON34-werx

Resin spacer

volume

8.6cc 8.2cc 7.5cc

Rubber spacer

volume

7.5cc-15mm 7.5cc-15mm 7.5cc-15mm 5cc-10mm

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Resin spacer 5 5 3 3 3 3

Rubber spacer

Travel

200mm

180mm 2 6 1 6

170mm 3 6 2 6

160mm 4 6 3 6 7 10

150mm 4 6 8 10

140mm 9 10

130mm

120mm 3 8

110mm 3 8

100mm 3 8

Air system forks

Number of Air volume spacers (rubber clip type)

AION35 ZERON35 AXON32 MOBIE34-air MOBIE45-air

Rubber

spacer

volume

5cc 5cc 4.3cc 5cc 5cc

Travel

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

Factory

setting

Max.

possible

spacers

160mm 3 6

150mm 3 6 3 6

140mm 3 6 3 6

130mm 3 6 3 6

120mm 3 6 2 4

100mm 2 4 2 5 2 5

80mm 2 5 2 5

60mm 2 5

Note:

Don't exceed the Maximum Volume spacers number because this can damage your fork.

14

COIL SPRING PRELOAD

The fork can be adjusted to the rider's weight and preferred

riding style via the spring preload. It is not the coil spring

hardness that is set, but the spring preload. This reduces the

“SAG” of the fork when the rider sits down. A medium

hardness spring is used as standard setting. Turn the preload

adjust knob clockwise to increase the spring preload and turn

it counter-clockwise to reduce it. Two additional spring

hardnesses are available for SR SUNTOUR suspension forks -

softer and harder than the standard coil spring.

MAINTENANCE OF THE FORK

As long as moving parts are exposed to moisture and contamination, the performance of your

suspension system might be reduced after several rides. To maintain high performance, safety

and long life of your suspension system, periodic maintenance is required.

Ø A suspension system which has not been serviced in accordance with the maintenance

instructions will not be covered under warranty.

Ø Never use a pressure washer or any water under pressure to clean your suspension fork as

water may enter the fork at the dust seal level. Never use aggressive cleaners. We

recommend clear water and a damp cloth to wipe down your fork.

Ø Your suspension fork should be serviced more frequently as indicated below if you ride in

extreme weather (winter time, or in wet/muddy conditions) and rough terrain conditions.

Ø If you believe that your suspension system performance has changed or handles differently,

immediately contact your local dealer to inspect your fork.

Ø After every ride: Clean the fork stanchion tubes and dust seals and maintain with an oily

cloth. Check stanchion tubes for dents, scratches or other discoloration or leaking oil.

Ø Every 50 hours: Maintenance 1 (at dealer)

Ø Every 100 hours or once a year: Maintenance 2 (at dealer, ideally before winter time in

order to protect all parts from the effects of weather by proper greasing)

MAINTENANCE 1:

Check function of fork / check torques of mountings screws and nuts on bottom of lowers

(suggested tightening torque: bolt: 10Nm, nut: 8Nm) / check for scratches, dents, cracks,

discoloration, signs of wear and signs of minor corrosion (maintain with oily cloth), or oil leaks.

MAINTENANCE 2:

Maintenance 1 + disassembly / cleaning the entire fork inside and out / cleaning and lubricating

dust seals and slider sleeves / checking torques / adjusting to the riders liking.

Before disassembly, check the slider sleeve play of the fork. To do so, apply the front wheel

brake and gently push the bicycle back and forth at the handlebar stem shaft. Replace the slider

sleeves if the play is excessive (more than 1 mm at the fork brace).

15

INTENDED USE

Pedal assist E-

bike (EU speed

pedalec or US-Class 3)

Pedal assist E

-bike (EU

pedalec

or US-Class 1 & 2): on-road

Pedal assist E

-bike (EU

pedalec

or US-Class 1 & 2): off-road

Cross bike

Trekking bike

City bike

Down hill bike

Enduro bike

All moutain bike

Cross country racing bike

Cross country bike

Warning Warning Warning Warning Warning Warning Warning Warning Warning Warning Warning

USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR USE ONLY FOR

Pedal assist bikes

EU speed

pedalec

or US

-Class 3 for

on

-road or casual

off

-road use

Pedal assist bikes

EU

pedalec or US-

Class 1 & 2 for on

-

road use

Pedal assist bikes

EU

pedalec or US-

Class 1 & 2 for off

-

road use

Paved road or

casual off

-

road use

Paved road or

casual off

-

road use

Paved road use

Downhill

Cross country, Trail

and Enduro use

Cross country, Trail

and All moutain

use

Cross country

racing and cross

country use

Cross country use

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

DO NOT USE FOR

Downhill,

Enduro

,

All mountain, Cross

country racing,

Cross country

Downhill,

Enduro

Downhill

Downhill,

Enduro

,

All mountain, Cross

country racing,

Cross country

Downhill,

Enduro

,

All mountain, Cross

country racing,

Cross country

Downhill,

Enduro

,

All mountain, Cross

country racing,

Cross country

Downhill

Downhill

Downhill,

Enduro

,

All mountain

Downhill,

Enduro

,

All mountain, Cross

country racing

MOBIE34

O O

MOBIE45

O O

MOBIE25

O

MOBIE

-A32 O O

MOBIE

-A32 20" CRG O O

XCT

-ATB O

GVX32

-15 O O

NRX32

O O

NRX30

O

NVX30

O

NCX

O O O

NEX

-E25 O O

CR85

-E25 O O

TR

-HSi O O

NEX

O O

M3010

O O O

M3010 24"/20"

O O

CR8

O

CR7

O

RUX38 BT

O O

DUROLUX38 BOOST

O O

DUROLUX36 BOOST

O O

AURON35 BOOST

O O

AURON34

O

AION35 BOOST

O O

AION34

O

ZERON35 BOOST

O O

AXON34

werx BOOST O

AXON34 elite BOOST

O

AXON32

werx O

AXON34 BOOST

O O

AXON32 BOOST

O

AXON32

O

EPIXON

O

RAIDON34 BOOST

O O O

RAIDON32 BOOST

O

RAIDON32

O

XCR34 BOOST

O O O

XCR32 BOOST

O

XCR32

O

XCR24"

O

XCM34 BOOST

O O O

XCM32 BOOST

O

XCM32

O

XCM

O

XCM 24" BT

O O

XCM

-JR. 20" O O

XCT30

O O

XCT 24” plus

O O

XCT28 L24"

O O

XCT 20” plus

O O

XCT L20"

O O

XCT 24"/20"

O O

XCE28

O O

CUSTOMER SUPPORT OFFICES

WEB LINKS

For further information please visit www.srsuntour-cycling.com. There you will also find:

u Service request: http://www.srsuntour-cycling.com/service/service-request

u Tech videos: http://www.srsuntour-cycling.com/service/tech-videos

u Download area: http://www.srsuntour-cycling.com/service/download-area

u Owners manuals: http://www.srsuntour-cycling.com/ja/service/download-area/consumer-

downloads/bike/owners-manuals/general-fork-manual/

u Fork glossary: http://www.srsuntour-cycling.com/service/fork-glossary

u Warranty: http://www.srsuntour-cycling.com/service/warranty

Copyright © 2020 SR SUNTOUR Inc. All rights reserved.

KAE260

ASIA, OCEANIA

SR SUNTOUR INC.

#7 Hsing Yeh Road

Fu Hsing Industrial Zone

Chang Hua, Taiwan, R.O.C.

Tel: +886-(0)4-769-5115

service@srsuntour.com.tw

SR SUNTOUR INTERNATIONAL CO., LTD.

No. 1500 Honghu Road, Penglang

Kunshan, Development Zone

Jiang Su Province, China ZIP 215333

Tel: +86-512-5517-1127

sr-service@srsuntour.com.cn

SRS INTERNATIONAL TRADING LTD.

Room 501, 5

th

floor, Building No. 2

Jiaxing Industrial Zone, Shubei Road

Gongming Town, Guangming District

Shenzhen City, China 518106

Tel: +86-755-271-084 83

service@srsuntour.com.cn

SR SUNTOUR JAPAN

NR Bldg. 4F, 3-13-13 Kuramae

Taito-ku, Tokyo, 111-0051

Tel: +81-3-5829-9211

EUROPE

SR SUNTOUR EUROPE GmbH

Riedstrasse 31

83627 Warngau, Germany

Tel: +49-(0)802-150-793-0

service@srsuntour-cycling.com

SR SUNTOUR Technical Service Center

Max-Planck-Str. 4

97526 Sennfeld, Germany

Tel: +49-(0)9721-473-4896

service@srsuntour-cycling.com

SAV SR SUNTOUR FRANCE

604 voie Galilee

73800 Sainte Helene du Lac, France

Tel: +33-(0)981-241650

sav@srsuntour-cycling.com

USA

SR SUNTOUR North America Inc.

7509 S. 5

th

Street Suite 124

Ridgefield, Washington 98642

Tel: +1-360-737-6450

Sales: ssna@srsuntourna.com

Service, warranty: service@srsuntourna.com

SR SUNTOUR Madison

910 Watson Avenue

Madison, Washington 53713 USA

Tel: +1-608-229-6610

service@usulcorp.com