DEPARTMENT OF THE AIR FORCE CFETP 21RX

Headquarters US Air Force Parts I and II

Washington, DC 20330-1030 30 June 2017

AFSC 21RX

LOGISTICS READINESS OFFICER

CAREER FIELD EDUCATION

AND TRAINING PLAN

ACCESSIBILITY: Publications and forms are available on the e-publishing website at

www.e-publishing.af.mil for downloading or ordering.

RELEASABILITY: There are no releasability restrictions on this publication.

1

LOGISTICS READINESS BADGE

Combines the falcon, oval wreath, and globe with one lightning bolt and

quartermaster key to denote the logistics readiness competencies of 1) Supply

Management and 2) Deployment, Distribution, and Transportation (DDT).

HERALDRY

The falcon at the center symbolizes the Air Force. It also symbolizes American

military strength, dedication, and devotion to duty of Logistics Readiness Officers

who support the generation and employment of aerospace forces across the

spectrum of warfare. The globe with three encircling arrows is symbolic of the

extensive range of our logistics support mission and capability to sustain our

forces by land, sea, or air. The key symbolizes the security, safekeeping, and

control of materiel in the old “Quartermaster Corps” tradition. The lightning bolt

symbolizes the integrating role of contingency operations and the capability to

combine essential logistics elements into a coherent plan supporting the

warfighter. The olive branch surrounding the badge symbolizes the peace

aerospace forces provide through a professional LRO group.

Wear the basic badge after graduating from the Logistics Readiness Officer Basic Course. Wear the senior

badge after having completed training requirements in three of the five primary logistics readiness

proficiencies of Supply, Transportation (Ground or Air), Fuels, Vehicle Management and Logistics Plans

and after having completed 7-years as an LRO. Additionally, the LRO must complete certification

requirements for both competencies (Supply Management and DDT). Wear the master badge at the 15-

year point, having completed all training requirements.

NOTE: Interservice transfers that have completed another services logistics course are authorized to

wear the LRO Basic Badge with documented approval from the MAJCOM A4R or 21R MAJCOM

Functional Manager.

2

CAREER FIELD EDUCATION AND TRAINING PLAN

LOGISTICS READINESS OFFICER (LRO) SPECIALTY

AFSC 21RX

TABLE OF CONTENTS

PREFACE

4

PART I

Section A - General Information

6

Purpose of the

CFETP

CFETP Uses

Coordination and

Approval

Section B - Career Field Description, Training and Progression

7

The Logistics Readiness Officer Career

Field

The Logistics Readiness Officer and Developing the Force

Implementation/Qualification Requirements

Section C - Competency Training

Requirements

13

AFSC Prefixes

21R4 DAFSC

Section D - Resource Constraints

14

PART II

Section A - Course Training

Standards

15

Task, Knowledge, and Competency

Level

requirements

Section B - Training Course Index

16

Purpose

AFSC Awarding Courses

Non-AFSC Awarding Courses

3

TABLE OF

CONTENTS CONTINUED

Section C – Support Material

17

Section D - LRO Proficiency Training Record

18

Charts

Chart 1. Logistics Readiness Competencies and Proficiencies

7

Chart 2. Career Progression

12

Chart 3. LOOP

19

Chart 4. LRO Training Records Levels of Understanding

20

Chart 5. General Roles and Responsibilities Training Matrix

20

Chart 6. Logistics Plans Training Matrix

22

Chart 7. Transportation (Ground) Training Matrix

27

Chart 8. Transportation (Air) Training Matrix

30

Chart 9. Supply Training Matrix

33

Chart 10. Vehicle Management Training Matrix

41

Chart 11. Fuels Training Matrix

43

Chart 12. Life Cycle Logistics Training Matrix

47

Table

Table 1. Qualification Requirements

11

Attachments

Attachment 1: Course Training Standards, Logistics Readiness Officer Basic Course

48

Attachment 2: Logistics Readiness Officer Training Courses

60

Attachment 3: Terms Explained

Attachment 4: 21R Specialization Track

67

72

_____________________________________________________________________________

OPR: 344 TRS/TRR

Certified by: AF/A4LR, Col Jeanne I. Hardrath

Supersedes: CFETP 21RX, dated 1 August 2013

Pages: 77

4

PREFACE

“Strategic Context: New Air Force operating concepts are evolving to meet the changing global threat

requiring new logistics operating concepts to support them. In turn, this will require new knowledge,

skills, and abilities in our officer, enlisted, and civilian workforce that align to the way we must operate in

the future. These changes must be identified and implemented across the near, mid, and long-term

planning time frames.

Vision: We must be able to deliberately, repeatedly, and affordably deliver high quality, integrated, agile

Total Force Integration (TFI) logisticians, across all planning time horizons, with the right competencies,

at the right place, at the right time to provide agile logistics support of Global Vigilance – Global Reach –

Global Power.”

Air Force Logistics Human Capital Strategy, 2016

1.0. Logistics Readiness Officers, encompass the integration of logistics disciplines for air and ground

transportation, supply management, fuels, vehicle management and logistics plans. Their responsibilities

include directing integrated logistics processes, accomplishing joint logistics planning for warfighting

support and sustainment with the joint staff, unified commands, other military services and agencies of

the Office of the Secretary of Defense and directing acquisition, retail and wholesale logistics activities.

2.0. The CFETP: The CFETP consists of two parts that are used to plan, manage, and control training

within the 21R career field. Officers, supervisors, and commanders will use each part to plan, manage,

and execute career field-specific education and training.

2.1. Part I contains four sections and provides information necessary for overall management of training

in the career field. Section A explains how to use the plan; Section B identifies career progression

information, duties and responsibilities, training strategies; Section C associates each skill level with

qualifications (knowledge, training, education, experience, etc.); and Section D indicates resource

constraints in formal/unit training (i.e. funds, manpower, equipment, facilities).

2.2. Part II describes education and training venues, as well as the mechanics for accomplishing required

education and training. Section A identifies Course Training Standards (CTSs); Section B identifies

required and additional education & training venues; Section C Support Material; Section D identifies the

LRO Proficiency Training Record.

3.0. Using the CFETP: The following individuals must utilize this CFETP to ensure LROs receive

effective and appropriately-timed education & training and skill-enhancing experience at appropriate

stages in their development. At the unit level, commanders, supervisors and trainers will use Part II to

plan and conduct training commensurate with the requirements directed by this plan. Additionally,

individuals occupying the following positions must comply with but are not limited to the following

duties and responsibilities:

3.1. Individual: Individuals should complete CFETP core requirements for upgrade from 21R1 to 21R3

within 48 months of being assigned to a 21R position. Check records to ensure 21R3 certification has

been awarded. With prior coordination and approval from their squadron commander (or equivalent), Air

Reserve Component (ARC) members may extend this requirement to 72 months to accommodate

availability constraints. Individuals will also complete required education & training requirements for

upgrade to senior and master skill levels as directed by this plan.

3.2. Unit Training Manager: Responsibilities are outlined in AFI 36-2201, Air Force Training

Program Career Field Education and Training. Responsibilities include (but are not limited to) loading

5

member’s CFETP into Training Business Area (TBA), assisting supervisors and commanders with

tracking/managing completion of Competency Training Matrices (Part II, Section D), and granting

supervisors and commanders access to electronic training records. Field grade and above LROs, with at

least a senior rating, do not require training records; however, the unit will ensure training is accurately

identified in readiness reporting systems.

3.3. Supervisor/Operations Officer: Supervisors and Operations Officers will ensure trainees

understand fundamentals of each Proficiency Training Matrix task, manage and control officer

progression through competency training, and document training completion in TBA and the Military

Personnel Data System (MilPDS). Supervisors and Operations Officers will also determine work center

rotations, identify local training tasks and conduct documented quarterly training progress review with

trainee, verify pre-task/task/post-task actions are included for follow-on training and certify completion of

training.

3.4. Squadron Commander: Squadron commanders (or equivalent) are responsible for ensuring

assigned officers meet requirements prescribed in this CFETP. Squadron commanders (or next higher

authority) will certify competency training progression by documenting task completion in TBA. These

responsibilities may be delegated to the squadron Operations Officer. Commanders will also certify

award of the 21R3 AFSC and senior certification via submission of an AF Form 2096, Classification/On-

The-Job-Training Action, to their local Force Support Squadron (FSS) for final disposition.

3.5. MAJCOM A4R: MAJCOM A4Rs or 21R MAJCOM Functional Manager will abide by

responsibilities outlined in AFI 36-2201.

6

PART

I

SECTION A - GENERAL INFORMATION

1.0. Purpose of the CFETP. This CFETP contains and provides information for career field functional

managers, commanders, supervisors, trainers, and the technical training centers to plan, develop, manage

and conduct a robust career field training program. This plan identifies initial skills, upgrade,

qualification, advanced, and continuation training.

1.1. Serves as a management tool to plan, develop, manage, and conduct a career field training program;

it is also used to ensure established training is provided at the appropriate points throughout an officer’s

career.

1.2. Identifies requirements for each skill level and recommends training for each phase of an officer’s

career.

1.3. Lists training courses available in the specialty, identifies sources of training, and provides the

training medium (See Attachment 2).

2.0. CFETP uses. This is the comprehensive plan to ensure a cohesive training program is instituted for

each officer.

2.1. Air Education and Training Command (AETC) develops/revises formal resident training based on

user requirements documented in this CFETP. AETC is responsible for developing procurement and

acquisition strategies to obtain the resources required to provide training identified in the CFETP. The

AETC Course Training Manager (AETC CTM) and the Air Force Career Field Manager (AFCFM) are

the custodians of this CFETP and ensure HQ AFPC/DP2LL receives approved revisions for publication.

The AETC CTM is responsible for notifying HQ AETC to index the CFETP in http://www.e-

publishing.af.mil.

2.2. The AFCFM will schedule and chair a Utilization and Training Workshop (U&TW) at a minimum

of every 3 years to address the training needs of the career field. The AFCFM will also ensure the

CFETP is validated annually, and updated as needed.

2.3. Squadron commanders use this plan to develop and implement a tailored training program for

officers assigned to their squadrons by reviewing CFETP-directed training requirements and the officer’s

existing documented training accomplished in previous assignments. In addition, squadron commanders

will ensure each officer’s training plan is maintained and tracked in the TBA.

3.0. Coordination and approval. The CFETP is approved and maintained by the Air Force Career

Field Manager (AFCFM) in accordance with (IAW) AFI 36-2201, Air Force Training Program Career

Field Education and Training. Forward recommended changes to the AFCFM, HQ USAF/A4LR.

MAJCOM requests for CFETP updates to include additional training requirements must be submitted to

the AFCFM prior to the annual validation of the CFETP. The AFCFM is the approval authority.

MAJCOM representatives and AETC training personnel will identify and coordinate career field training

requirements. The AETC CTM for AFSC 21R will coordinate with the AFCFM to initiate an annual

MAJCOM review of this document to ensure currency and accuracy.

4. Use of TBA is mandatory for all Active, Guard, and Reserve personnel to document CFETP

requirements. Contact the MAJCOM 21R functional manager if unable to comply with this mandate.

7

PART

I

SECTION B - CAREER FIELD DESCRIPTION, TRAINING AND PROGRESSION

1.0. Logistics Readiness Officer Career Field. The 21R AFSC Competency areas of Supply

Management and DDT align with Joint Publication (JP) 4-0 Joint Logistics core logistics capabilities and

the DoD Logistics Human Capital Strategy (LHCS) Core Competencies. Outlined in the chart below:

Chart 1. Logistics Readiness Competencies and Proficiencies

COMPETENCIES

Supply

Management

Deployment,

Distribution and

Transportation

(DDT)

PROFICIENCIES

Supply

Vehicle

Management

Transportation

(Ground or Air)

Logistics Plans

Fuels

Life Cycle Logistics

1.1. Logistics Readiness Competency Definitions. The following paragraphs from the Logistics

Human Capital Strategy describe the career field Competencies:

1.1.1. Supply Management. Skills include the ability to accurately forecast requirements, identify and

select supply sources, schedule deliveries, receive, store, verify and transfer product, and authorize

supplier payments.

1.1.2. Deployment, Distribution, and Transportation. Ability to plan, coordinate, synchronize, and

execute personnel and cargo movement and sustainment tasks in support of military operations.

1.2. Logistics Readiness Proficiency Definitions. The following paragraphs from the Air Force Officer

Classification Directory (AFOCD) describe the career field and its proficiencies:

1.2.1. Supply. Directs materiel management operations to include direction and management of retail or

wholesale supply activities. Included are environmental compliance and inventory management.

Determines, computes, and analyzes current and projected materiel requirements; applies authorizations

and allowances; establishes and maintains non-demand based stock levels; manages asset positioning;

inspects, reviews, and evaluates work methods and procedures. Ensures accountability is maintained for

supplies, equipment, Nuclear Weapons Related Materiel (NWRM), War Reserve Materiel (WRM) and

Mechanized Materiel Handling Systems (MMHS). Determines effectiveness of functional data systems.

Manages assigned information systems and applies approved standards and criteria to ensure proper

implementation, operation, and results. Develops plans, programs, policies and procedures to manage

8

materiel management activities, including analysis, determination and computation of requirements, asset

serviceability and shelf life management, plans for mission changes facility requirements, equipment

allowances, and materiel accounting. Executes working capital fund and determines budget requirements.

Provides guidance on handling of readiness materiel stocks, including location, type of storage,

protection, security, and quality control.

1.2.1.1. Supply Chain. The DoD supply chain is a global network that provides materiel, services, and

equipment to the joint force. The fundamental goal of the supply chain is to understand the requirements,

maximize force readiness and optimize the allocation of joint resources. The functional capabilities that

contribute to the DoD supply chain include management of supplies and equipment, inventory

management, repair chain, management of global supplier networks, and assessment of global

requirements, resources, capabilities, asset disposal and risks. The DoD’s supply chain responsiveness

and reliability affects the readiness and capabilities of US military forces and is critical to the overall

success of joint operations.

1.2.1.2 Supply Chain Management. Supply chain management involves identification and

coordination of requirements, planning and synchronizing joint supply activities throughout DoD, and

managing key global suppliers to support Combatant Commander requirements. Critical elements of

supply chain management include understanding and prioritizing requirements; visibility of forces as they

maneuver, identifying mission-essential weapon systems and equipment; visibility of materiel moving

through the distribution pipeline; ability to accurately forecast demands for sustainment; and prioritization

of supply tasks in the area of responsibility (AOR). Operational planners can work with logistics planners

to optimize supply chain operations and identify requirements to providers. Planners identify mission

priorities, assess risks, and plan for the protection of the supply chain in the operational theater.

Additional responsibilities include planning for secure storage and disposition of hazardous materials,

planning to retrograde material and equipment, and establishing Joint Logistics Enterprise visibility of

materiel requirements.

1.2.1.3. Supply Chain Areas. Joint logisticians must integrate all three areas of the DoD supply chain:

managing supplies and equipment, managing inventory, and managing global supplier networks to

provide responsive supply operations.

1.2.2. Vehicle Management. Directs vehicle management operations to include coordination of vehicle

and equipment requirements, allocations, priorities, and warranty repairs. Evaluates quality of operator

care and maintenance. Determines operational requirements and specifications including reliability,

maintainability, and standardization for facilities, vehicles and materiel handling equipment. Develops

policies and procedures for the administration of vehicle accidents and abuse programs. Collects and

analyzes data on vehicle operations and maintenance. Manages compliance with Air Force energy

objectives for leased and Air Force owned ground vehicles.

1.2.3. Fuels. Directs fuels operations including environmental compliance and inventory management of

ground fuel, aviation fuel and cryogenics. Determines petroleum provisions, computes and analyzes

current and projected petroleum and cryogenic requirements; computes, establishes and maintains stock

levels to meet peacetime and wartime requirements; manages fuel received from pipeline, tank trucks, rail

cars, and marine vessels. Manages fuel dispensing systems, fuel storage facilities, cryogenic storage and

production, and sample and test fuel samples. Develops and plans procedures to manage fuel activities

including system design, plans for mission changes, facility requirements, equipment allowance, required

reporting and accounting. Interprets fuels directives. Inspect, reviews and evaluates work methods and

procedures. Resolves problems related to commander, staff and operating units on peacetime, wartime

and contingency fuels support. Coordinates with elements of DoD and other governmental organizations

to assure support to customers.

9

1.2.4. Life Cycle Logistics. Directs acquisition/life cycle logistics activities. Plans for and manages

systems, subsystems, and equipment throughout their life cycle, including integrated logistics support

activities and modernization/obsolescence planning. Develops, initiates, integrates, and manages all

logistics actions associated with life cycle management of weapon systems, subsystems, and equipment.

Serves as logistics focal point throughout the system’s life cycle. Formulates logistics requirements for

weapon systems.

1.2.5. Transportation. Directs Transportation operations to include managing cargo distribution

functions including receiving, inspecting, tracing, tracking, packaging, and shipping of supplies, NWRM,

equipment, and war readiness spares. Responsible for logistics pipeline management and time-sensitive

delivery of materiel in support of peacetime, contingency, and wartime operations. Maintains in-transit

visibility for shipments of personal property, passengers, supplies and equipment.

1.2.5.1 Ground Transportation. Responsible for the safe and efficient transportation of personnel and

cargo within and between installations in support of daily and contingency operations. Resolves

problems related to shipment staging, safety, and fire hazards. Manages shipment storage space

utilization and develops and maintains a shipment storage facility and mechanized material handling

equipment modernization program to include maintenance, future upgrades, and working stock

requirements. Determines readiness requirements, including emergency supply support plans, tactical and

strategic movement of personnel, materiel, and units. Schedules and coordinates movement of cargo,

personnel, and personal property by commercial or military modes using systems that interface with

defense total asset visibility systems. Uses In-Transit Visibility (ITV) systems. Coordinates with

elements of DoD and other governmental organizations to assure support to customers. Ensures proper

allocation and effective use of transportation resources. Establishes and administers an effective

packaging and preservation program. Evaluates movement forecasts and flow of personnel and cargo into

the transportation system, movement capabilities, and efficiency of modes used.

1.2.5.2. Air Transportation. Directs aerial port operations including management of fixed and mobile

air terminals through various sub-processes to include: Fleet Services, Aerial Delivery, Passenger

Terminals, Freight, and Air Terminal Operations. Coordinates transportation support requirements and

capabilities with other agencies using DoD and USAF logistics, transportation, and ITV systems.

Evaluates movement forecasts and flow of personnel and cargo into the most efficient mode of the

Defense Transportation System.

1.2.6. Logistics Plans. Directs peacetime, contingency, and wartime logistics planning operations

including deployment command and control, Logistics Readiness Centers, Combat Support Center

activities, deployment, bed-down, and redeployment activities. Integrates Combat Support planning

efforts, conducts readiness assessment of logistics activities, conducts contingency planning, base support

and expeditionary site planning, WRM management, support agreement management, Acquisition Cross-

Servicing Agreements, manages logistics Time-phased Force Deployment Data and Unit Type Codes.

Enables international theater security cooperation and interoperability, operating in coalition or Joint

environments often working with contractors, host-nations.

2.0 Develop and Manage the Force: As stated in the Logistics Human Capital Strategy, the Logistics

Board directed AF/A4L to develop a logistics workforce to equip logisticians with the requisite training

and education for business acumen to effectively lead and transform a vast $17B logistics enterprise; from

the industrial base to the flightline. This initiative is a purposeful education and focused training roadmap

that supports career path progression across key logistics competencies and proficiencies. It includes

courses designed to provide targeted education to Airmen at the right time in their careers and technically‐

10

oriented education that is career field‐specific. It also includes tailored courses that are managed and

developed by the Air Force Institute of Technology (AFIT).

2.0.1. Develop and Manage the Force Internet-based training modules: These modules complement

On the Job Training and experience to ensure officers have a firm foundation in the two competencies.

These online courses are administered by the AFIT School of Systems and Logistics (AFIT/LS) and

Defense Acquisition University (DAU). See their websites for further information.

2.1. Skill Certification.

2.1.1. 21R3 Certification. Representative grades are normally O-1 through O-3. IAW the AFOCD, the

following are mandatory for 21R3 certification: An officer will complete the LRO Orientation Program

described in Part II, Section D prior to attending the LRO Basic Course, 48 months experience in at least

three (No less than 12 months in each) of the five proficiencies (Supply, Transportation (Ground or Air),

Vehicle Management, Logistics Plans, and Fuels); and completed requirements for both Competencies

(Supply Management and DDT). Those officers with proficiency training completion dates annotated in

their training record prior to the official date of this CFETP are grandfathered from the above

requirements. Prior enlisted experience will be considered for qualification. In order to qualify with

prior-enlisted experience, individuals must have attained a 5-level in supply (2SXXX), fuels (2FXXX),

logistics plans (2GXXX), or transportation (2TXXX). Furthermore, the officer’s prior enlisted rank must

be commensurate to a Non-Commissioned Officer (NCO).

2.1.2. Senior Certification. A fully qualified 21R3 will be eligible for award of the senior skill level

with 7 years of logistics officer experience (time spent outside of the career field in positions not coded as

21RX does not count toward senior certification) .

2.1.3. Master Certification. A fully qualified 21R will be eligible for the Master certification with 15

years of logistics officer experience. These qualified officers are ready to assume a broad spectrum of

leadership roles.

11

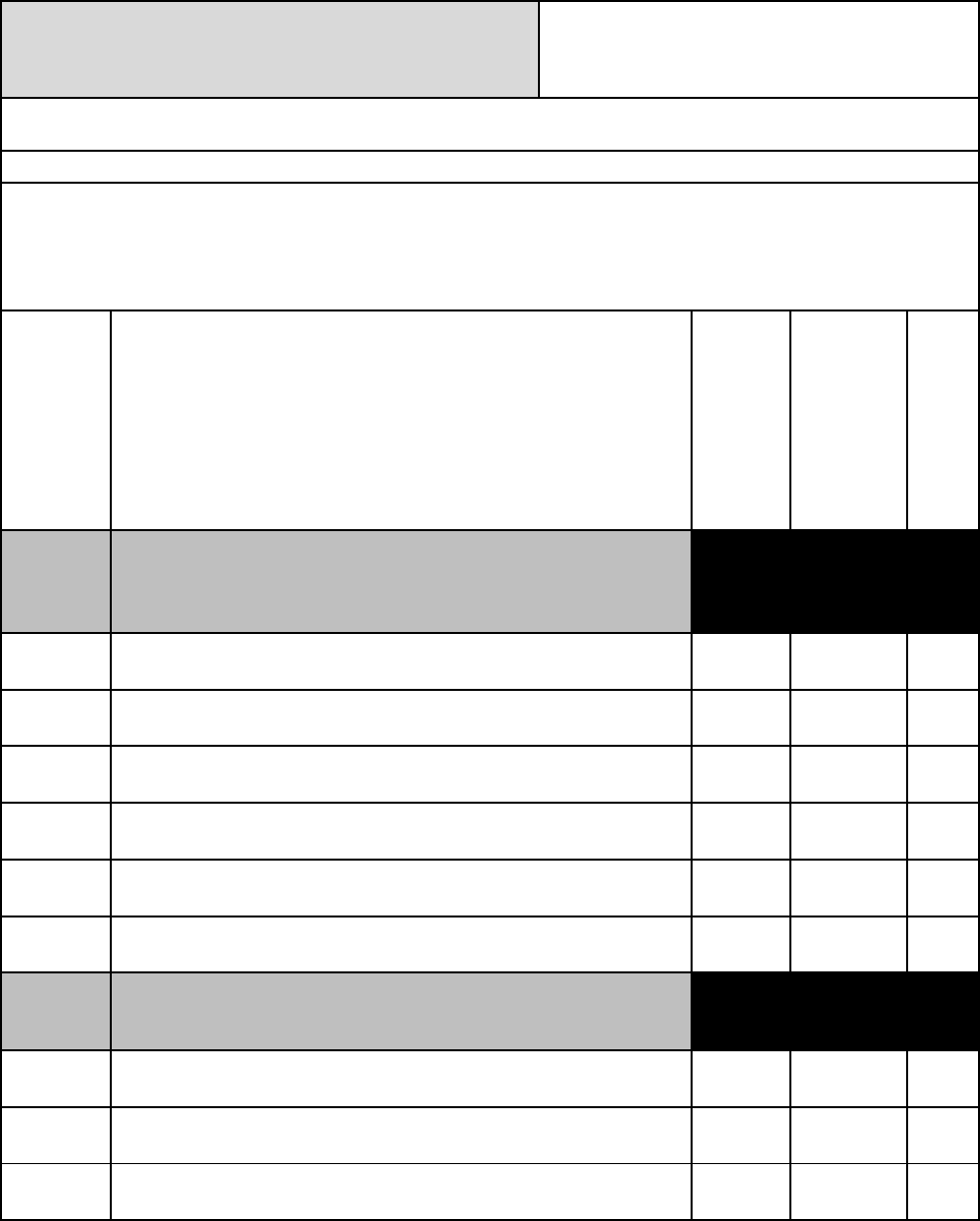

Table 1. Qualification Requirements

Logistics Readiness Officer Certification

To Obtain

Must Complete

Entry Level Cert

Senior Cert

Master Cert

Experience and

Training

Completion of LOOP

and Basic LROC

Training

Minimum 12

months in three of

the five

proficiencies and

signed off on all

tasks. Cumulative

time as 21R = 48

months

and completed

requirements for

both Competencies

(Supply

Management and

DDT)

Completion of all

previous

experience and

training from

LRO Basic and

21R3 and 7 Years

as 21R.

Additionally, must

complete

certification

requirements for

both competencies

(Supply

Management and

DDT)

15 years of

logistics officer

experience as a

21R.

These qualified

officers are ready

to assume a broad

spectrum of

leadership roles.

Completion of all

previous

experience and

training from LRO

Basic and 21R3

LRO senior

requirements

2.2. Career Progression. Experience and knowledge in this Air Force specialty will help officers plan

and achieve their Air Force career goals as LROs. There are certain jobs or experiences in this discipline

that will assist them in meeting individual goals. Consequently, training and experience complement one

another to develop officers with theoretical and practical mastery of the LRO skill sets. Chart 2 describes

the career path/training opportunities and outlines when training is required for career progression within

this specialty.

12

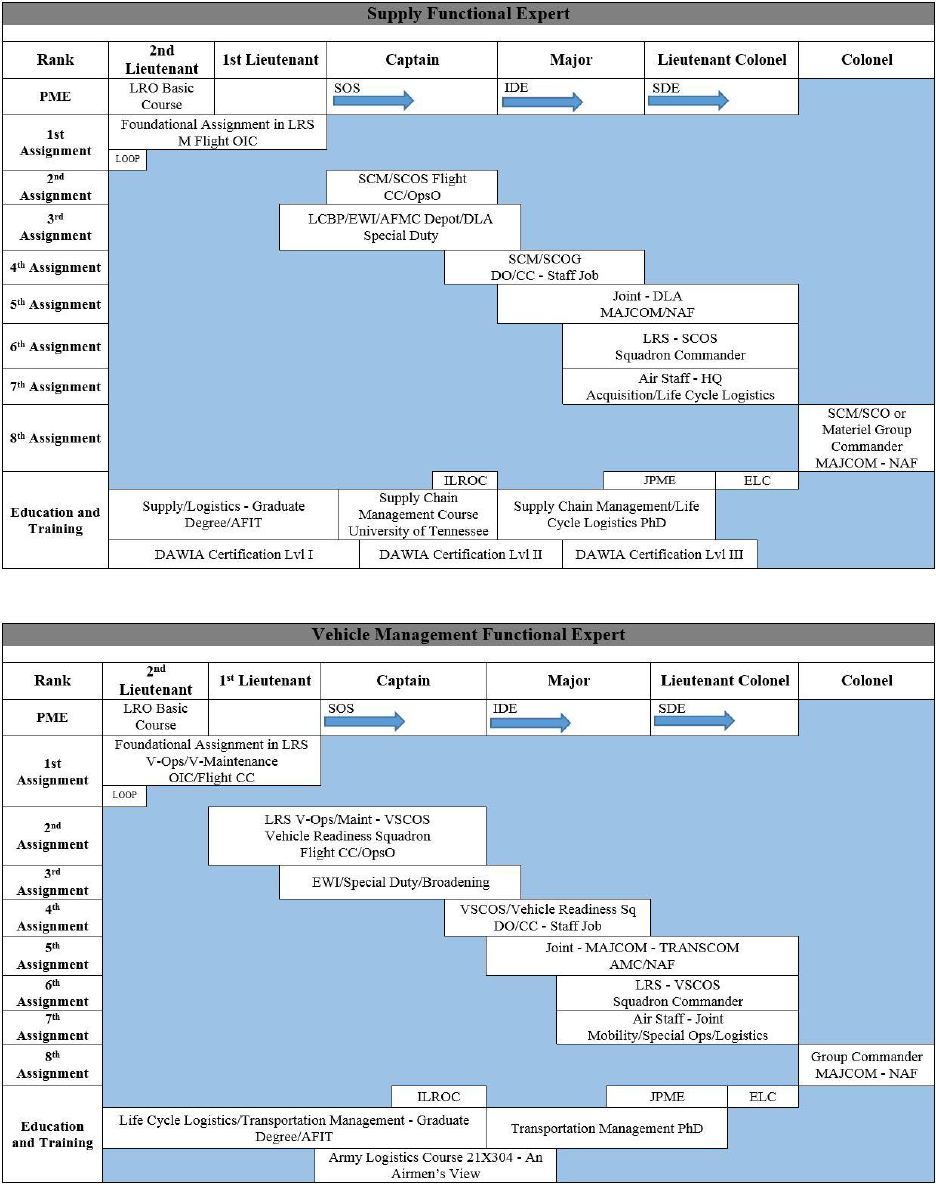

Chart 2. Logistics Readiness Officer Career Progression

2.3. Broadening Opportunities. At the 3-13 year point, RegAF LROs are competitively selected by the

DT for Special Experience and Exchange Duties (SPEED) Programs such as Logistics Career Broadening

Program (LCBP), Education with Industry (EWI), and Base Level Broadening Program (BLBP). After

award of 21R3, LROs are encouraged to seek out internal & external broadening opportunities. These

include instructor at the LRO Basic Course, ROTC, PME, OTS Instructor, Basic Military Training Flight

Commander and many others. Discuss opportunities outside of the 21R career field with your supervisors

and mentors; however, LROs are strongly cautioned to not accomplish back to back broadening

assignments.

13

PART

I

SECTION C –COMPETENCY TRAINING REQUIREMENTS

1.0. AFSC Prefixes. The Logistics Readiness AFSC prefixes and titles are located in the AFOCD.

Squadron Commanders will approve the award of prefixes based on requirements located in the AFOCD.

1.0.1 21R4 DAFSC. The 21R4 DAFSC is only held for the duration of an assignment at a NAF or

higher staff-level position. As a general rule, time spent outside of core duties (SOS, OTS, ROTC,

USAFA instructor, etc.) does not count towards the award of senior/master certification unless waived by

the Group Commander or equivalent.

14

PART

I

SECTION D - RESOURCE CONSTRAINTS

1.0. No Resource Constraints. No resource constraints were identified during the revision of the

Course Training Standards for all 21RX courses. Any resource constraints identified during course

revision will be forwarded for Course Resource Estimate and forwarded to AETC/A3TM Training

Pipeline Manager for resolution IAW AFI 36-2201.

15

PART

II

SECTION A - COURSE TRAINING STANDARD

1.0. Task, Knowledge, and Proficiency Level Requirements. These requirements are based on an

analysis of the duties contained herein and validated by the U&TW. The qualitative requirements for

each task are based on the Competency values listed on the Training Record Levels of Understanding in

Chart 5.

1.1. Customer Feedback. Unit supervisors will submit Field Evaluation Questionnaires (FEQ) on

officers who complete the formal LRO Basic Course training at Sheppard AFB. Respond to FEQs when

received from the technical training group (82 TRG and 363 TRS). (Reference AFI 36-2201)

1.2. Records Documentation. The CFETP will be issued at the first duty station. Completion of

training will be documented and certified. Upon completion of the in-residence LRO Basic Course,

students will receive a certificate of completion and a training report (AF Form 475, Education/Training

Report) and will include CFETP tasks accomplished at the Basic Course.

1.3. Logistics Readiness Officer Training Requirements by Course. The CTS is listed at attachment

1 of this CFETP. Task, Knowledge, and Competency Levels are included.

16

PART

II

SECTION B –TRAINING COURSE INDEX

1.0. Purpose. This section of CFETP identifies training courses available to the LRO. Squadron

leadership and training management personnel should use this information to plan, develop, and update

their respective Master Training Plan. The Education and Training Course Announcements (ETCA)

contains more detailed course information at the ETCA website (https://etca.randolph.af.mil/). Refer to

this site for more detailed course information.

2.0. AFSC Awarding Courses.

2.1. Logistics Readiness Officer Basic Course Training. This AFSC awarding course is to provide the

basic knowledge and skills needed to perform basic LRO duties. The goal is to send new LROs to the

Basic Course within their first 120 days of assignment to the unit. The scope of training includes

Introduction to Logistics, Basic Level Roles and Responsibilities, Supply, Fuels, Transportation, Vehicle

Management, Logistics Plans, Life Cycle Logistics, and Capstone exercises.

3.0. Non-AFSC Awarding Courses. See Attachment 2 for additional logistics training and education

opportunities.

17

PART

II

SECTION C - SUPPORT MATERIAL

1.0. Competency Training. Designed to build on concepts taught at the Basic Course and applied at the

unit level.

1.1. Concept. The intent of Competency training is to produce qualified Logistics Readiness Officers

and award the 21R3 skill level. Competency training consists of the tasks identified under the respective

proficiencies in Charts 6-13.

1.2. Master Training Plan. The instructional design for unit level training is determined locally. Unit

training may include work center and field visits, task observations, classroom instruction, self-study,

supervisor/commander interaction to meet training objectives.

1.3. Training Documentation.

1.3.1. Operation Officers/Squadron Commanders will review TBA with trainees at an initial interview

within 60-days (120 Days for ARC) of the trainee’s assignment to the unit. During the interview the

supervisor and trainee will discuss task requirements. Document the initial interview in TBA notes.

1.3.2. Operation Officers/Squadron Commanders will identify tasks the trainee will be required to

complete. As some installations may not have all the required equipment, supervisors will identify tasks

able to be completed in TBA. Any task that cannot be completed due to local limitations will be

documented in TBA. Every effort should be made by the trainee to meet the task requirement when able

(TDY, loaner equipment, etc.).

1.3.3. Operation Officers/Squadron Commanders will review training progress with trainees monthly

until training is complete. Documentation of this review will be in TBA.

1.3.4. Basic Course Instructors will sign off on all the standard CFETP tasks on a hard copy and/or

electronic one for the student’s parent unit to update TBA.

18

PART

II

SECTION D – LRO PROFICIENCY TRAINING RECORD

1.0 The LRO Proficiency Training Record is comprised of proficiencies of Supply, Fuels, Transportation

(Ground and Air), Logistics Plans, Life Cycle Logistics and Vehicle Management tasks. The officer must

be assigned to the work center for the required 12 months and complete the associated requirements for

completion of the proficiency. While not assigned to the corresponding work center, ARC members may

gain and document experience while on Annual Tour or Seasoning Training. ARC Unit Commanders

have discretion when evaluating the 12 month experience requirements based on the member’s

experience and other factors. Officers must accomplish all tasks in the area available on location (see

note below) and have the same recorded in TBA by their trainer before they petition their squadron

commander for completion of that proficiency. The commander will determine if a trainee requires

remedial training before approving a proficiency area completion.

NOTE: If the process is not available at a particular location, trainers may line through and initial the

process area. This action will waive the requirement for that specific process. However, commanders

must review/verify each lined through item prior to considering for upgrade to 21R3 and submitting an

AF Form 2096.

2.0. How to Use the LRO Training Record:

The commander/supervisor should use task experts to conduct LRO Proficiency training. Upon

completion of training, the trainer should make appropriate annotations in TBA.

3.0. LRO Orientation Program: The objective of this program is to provide a foundation for successful

completion of the Basic Course. LOOP should occur immediately upon arrival at first duty assignment,

but must be completed before attending the Basic Course. LOOP is a Squadron Commander’s program

and should consist of an initial interview and a detailed orientation of squadron functions and capabilities.

19

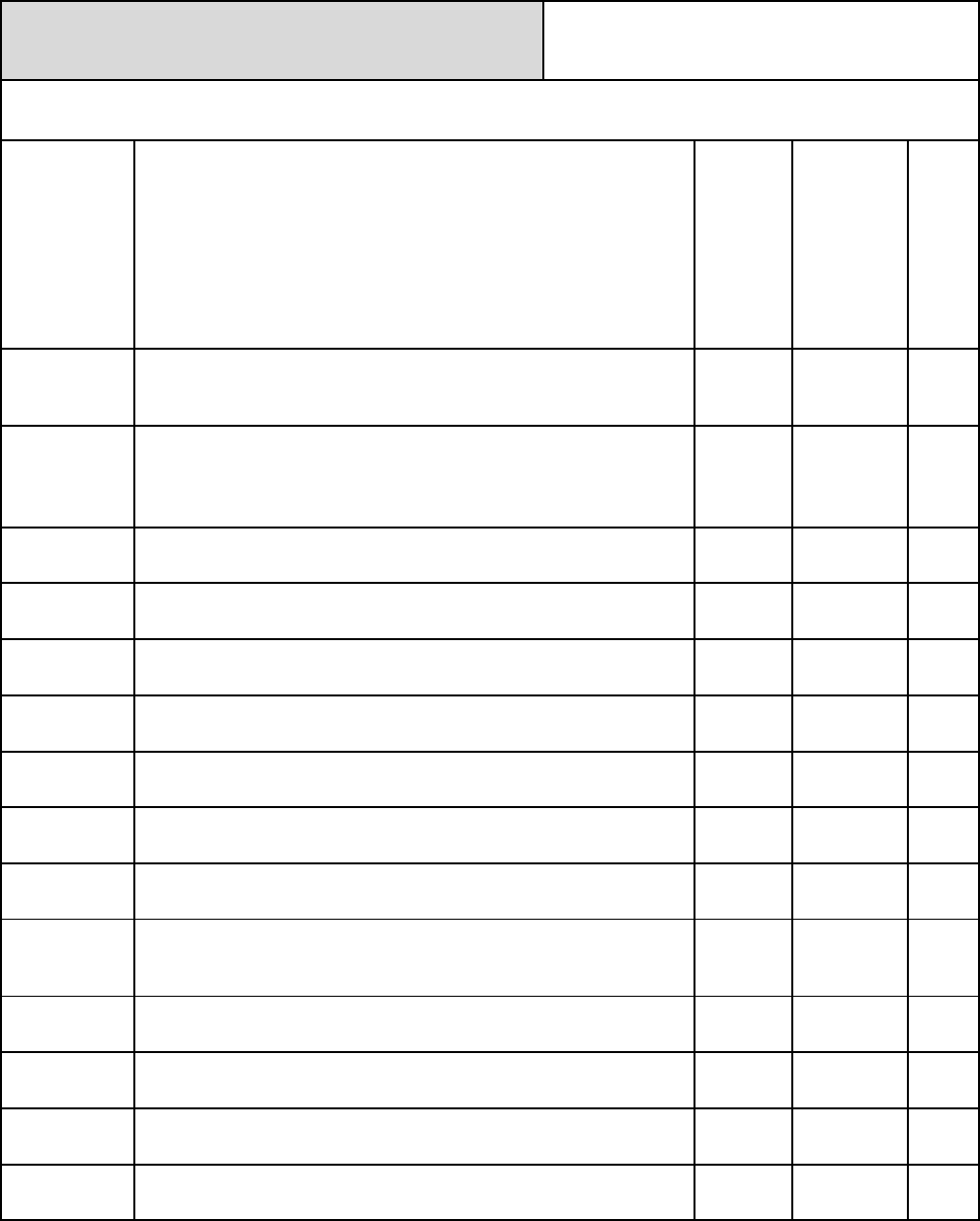

Chart 3. Logistics Readiness Officer Orientation Program (LOOP)

LRO Orientation Program

Operations Officer Signature/Date Completed

Note: To complete the LRO Orientation Program Matrix, the trainee MUST have ALL

processes/knowledge areas signed off.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

1

Initial Interview. The squadron commander accomplishes

initial interview to determine individual’s

experience/background

2

Orientations are to familiarize the officer with duties,

responsibilities, key personnel, and location of each

squadron/group/wing agency with a role in logistics support

(i.e. deployment machine). Tours and briefings will include:

2.1

Logistics Readiness Squadron and areas of responsibility

(flights and functions)

2.1.1

Operations Officer and areas of responsibility

2.1.1.1

Functions & responsibilities of Operations Compliance

2.1.2

Functions of the deployment machine; tour, receive a briefing

on each function (i.e., DCC, CDF, PDF, IDRC)

2.2

Aerial Port/Air Mobility Squadron areas of responsibility

(flights and functions, if available at base)

2.3

Supply Chain Operations Squadron and areas of

responsibility (if available at location)

3

Vehicle and Equipment Familiarization Training:

3.1

Vehicle familiarization training will provide general

familiarization on MHE, general-purpose and special purpose

vehicles

3.2

Logistics Automated Information Systems familiarization

4.0

Fuels Operations and areas of responsibilities

5.0

Familiarization and understanding of Squadron’s UMD and

UMPR

6.0

Familiarization and understanding of a Flight’s operating

budget (3400, 3080 etc.)

20

Chart 4. LRO Training Record Levels of Understanding

Each key process or knowledge area must be completed before

completing the Competency.

Identify

Recognize basic characteristics of task, function, item or process

Explain

Articulate in specific detail a task, function, item or process and the purpose thereof

Discuss

Consider or examine the task, function item or process and apply to a specific scenario

Analyze

The ability to review and interpret information regarding a task, function, item or process and

identify potential problems and/or develop courses of action

Conduct

Utilize acquired knowledge to perform a task, function or process

Chart 5. Logistics Readiness Officer General Roles and Responsibilities

General Roles and Responsibilities

Operations Officer Signature/Date Completed

Note: To complete the General Roles and Responsibilities Matrix, the trainee MUST have ALL

processes/knowledge areas signed.

Note: If a process/knowledge area is not available at a particular location, trainers may line through and initial

the process/knowledge area. This action will waive the requirement for that specific process; however,

commanders must review/verify each lined through process/knowledge area prior to submitting an AF Form

2096 to the FSS or local personnel function. Once a waived process becomes available due to PCS or other

change, commanders should ensure the individual is properly trained on that requirement.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

1.0

Roles and Responsibilities: THIS AREA WILL BE

COMPLETED DURING LRO BASIC COURSE AND ALL

COMPONENTS ARE PART OF THE CTS.

1.1

Explain the roles and responsibilities of installation level

logistics organizations

1.2

Explain the Logistics Readiness Competency

1.3

Identify the Logistics Human Capital Strategy

1.4

Explain the role of logistics in sortie generation and force

projection

1.5

Explain general safety policies and procedures within base level

logistics organizations

21

1.6

Explain environmental compliance standards within base level

logistics organizations

1.7

Explain the principles of Risk Management

1.8

Explain base level logistics compliance metrics and reports

1.9

Identify squadron resourcing, budgeting and execution process

1.10

Explain squadron readiness roles and responsibilities

1.11

Identify Air Force logistics support above wing level

1.12

Identify the structure and functions of Joint Staff/Air

Staff/MAJCOM

1.13

Identify logistics readiness competencies and joint logistics

functions and capabilities

1.14

Explain procedures for policy management at all levels

1.15

Explain the roles and responsibilities of Air Reserve

Components within the TFI structure

1.16

Identify and understand Financial Improvement and Audit

Readiness (FIAR) Roles responsibilities

1.17

Explain the roles, responsibilities, organizational structure and

mission of an Air Forces Forward (AFFOR) Staff

1.18

Explain the roles, responsibilities and mission of the Air Force

Installation Mission Support Center (AFIMSC)

1.19

Explain the roles, responsibilities, and mission of the Air Force

Sustainment Center (AFSC) and subordinate agencies (SCOW,

SCOG, VSCOS, SCMW, SCMG, etc.)

22

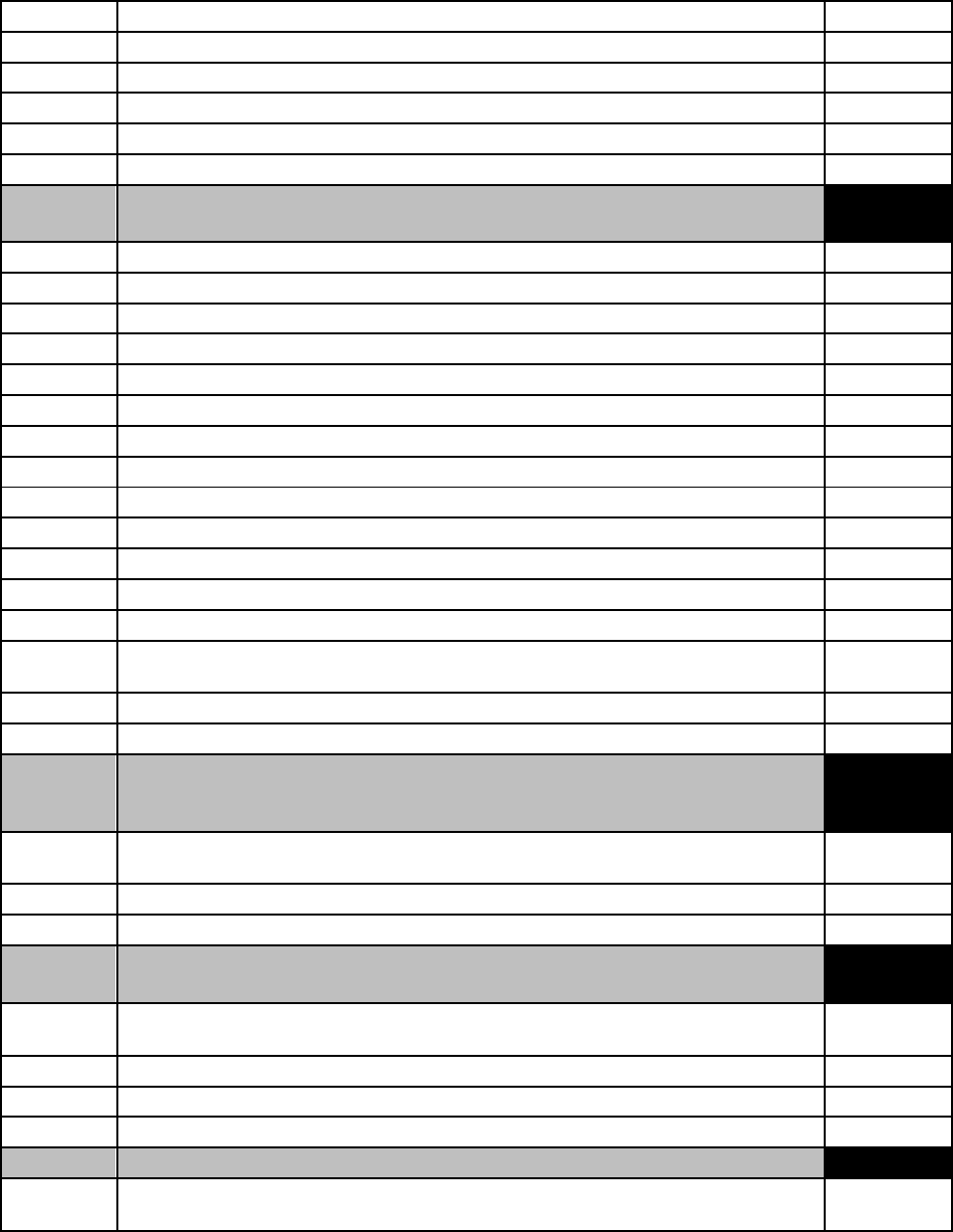

Chart 6. Logistics Plans Training Matrix

Logistics Plans

Operations Officer Signature/Date Completed

Note: To complete the Logistics Plans Training Matrix, the trainee MUST have ALL processes/knowledge

areas signed.

Note: If a process/knowledge area is not available at a particular location, trainers may line through and initial

the process/knowledge area. This action will waive the requirement for that specific process; however,

commanders must review/verify each lined through process/knowledge area prior to submitting an AF Form

2096 to the FSS or local personnel function. Once a waived process becomes available due to PCS or other

change, commanders should ensure the individual is properly trained on that requirement.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

2.0

Identify the capabilities of Logistics Plans Unit Type Codes

(UTC)

2.1

AEROSPACE PLANNING TR: JP 4-0; Vol 1, Basic

Doctrine; Vol 2, Leadership; AFI 10-401; AFI 10-402; AFI

10-403; AFI 10-1301; CJCSM 3130.06A

2.1.1

Explain National Mobilization

2.1.2

Identify the concepts of an Air Tasking Order and where they

originate

2.1.3

Explain the concepts of Combat Support

2.1.4

Explain how the UTC Availability Listing construct presents

forces to the Combatant Commander

2.1.5

Explain the principles and processes of Global Force

Management

2.1.6

Explain AEF Online Tools AFRIT (AF Reporting Instructions

Tool), CCTK (Commanders Tool Kit), DPDRT (Deployment

Processing Discrepancy Reporting Tool), PDPT (Personal

Deployment Preparedness Tool) & RPT (Reclama Processing

Tool)

2.2

LOG C2 - PLANNING SYSTEMS Integrated Deployment

System (IDS) TR: AFI 10-401; JP 4-0; JP 3-08; AFSC PUB

1; CJCSI 3100.01; CJCSM 3122.03

2.2.1

Explain the Joint Operation Planning and Execution System

(JOPES)

23

2.2.2

Explain the purpose of the Global Command and Control System

(GCCS)

2.2.3

Explain the relationship between JOPES and the Air Force

contingency planning process and systems Deliberate and Crisis

Action Planning and Execution Segments (DCAPES)

2.2.4

Identify purpose of LOGMOD

2.2.5

Analyze and execute the development of a passenger and cargo

LOGMOD schedule

2.3

PLANS MANAGEMENT TR: AFI 10-404; AFPD 10-4; AFI

10208; AFI 10-401; AFI 10-501

2.3.1

Explain the difference between the types of deployment orders

2.3.2

Conduct an exercise as the Installation Deployment Officer

(IDO) or Assistant IDO

2.3.3

Analyze and Explain OPLAN and associated orders

2.3.4

Explain the difference between shortfalls and limiting factors

(LIMFACs)

2.3.5

Explain the purpose of Joint and Air Force doctrine documents

2.4

PLANS MANAGEMENT - CONTINGENCY PLANNING

TR: JP 5-0; AFSC PUB 1; Vol 2, Leadership; AFI 10-401;

AFI 10-403; CJCSM 3122.01; CJCSM 3122.02; CJCSM

3122-03; CJCSM 3150.01

2.4.1

Analyze the War and Mobilization Plan (WMP) documents

2.4.2

Explain the planning phases of the contingency planning process

2.4.3

Analyze Time-Phased Force Deployment Data (TPFDD)

2.4.4

Analyze the Manpower, Equipment Force, Packaging

(MEFPAK)

2.4.5

Explain the UTC development and review process

2.4.6

Explain the role of and use of Operational Contract Support

(OCS) in planning and execution

2.5

PLANS MANAGEMENT - CRISIS ACTION PLANNING

TR: JP 5-0; AFSC PUB 1; AFDD2; AFI 10-401; AFI 10-403;

CJCSM 3122.01; CJCSM 3122.02; CJCSM 3122.03

2.5.1

Explain the phases of crisis action planning

2.6

INSTALLATION DEPLOYMENT ROLES &

RESPONSIBILITIES

TR: JP 4-0; Vol 1, Basic Doctrine; AFI 10-403; Vol 2,

Leadership; Annex 4-0 Combat Support; AFI 10-401; AFI

24

10-402; AFI 10-1301; AFPD 10-4; TR: FCAT 21-209;

LOGMOD ON-LINE HELP; WMP 1, ANNEX E

2.6.1

Explain role of Installation Deployment Officer (IDO)

2.6.2

Discuss the Joint Reception, Staging, Onward Movement and

Integration Concept (JRSO&I)

2.6.3

Explain concepts of force posturing (Warfighter and Institutional

Force)

2.6.4

Explain the difference between the various posturing codes

2.6.5

Explain pre-deployment planning

2.6.6

Identify deployment organizational structure (IDRC/DCC etc.)

2.6.7

Explain the purpose of the Installation Deployment Plan (IDP)

2.6.8

Explain and conduct Deployment Process Working Group

(DPWG)

2.6.9

Analyze and Execute Installation Deployment Readiness Cell

(IDRC) operations

2.6.10

Analyze and Execute Concept Brief

2.6.11

Explain Redeployment Planning

2.6.12

Explain Role of Unit Deployment Manager

2.7

BASE SUPPORT PLANNING

TR: AFI 10-404; AFI 10-403

2.7.1

Analyze and Execute Base Support Planning

2.7.2

Analyze LIMFACs in base support planning

2.7.3

Conduct Base Support Planning Committee and Review

2.8

READINESS REPORTING

TR: AFI 10-201

2.8.1

Analyze Designed Operational Capability (DOC) Statement

2.8.2

Explain resource readiness

2.8.3

Explain capability readiness

2.8.4

Explain Unit Type Code readiness

25

2.8.5

Identify readiness reporting systems

2.8.6

Explain METLs, where they’re located, how they’re assessed

and reported

2.9

SITE SURVEYS

TR: AFI 10-404

2.9.1

Explain site survey processes

2.9.2

Analyze site survey data/libraries (e.g. BaS&E, NGA, GDSS,

etc.)

2.10

WAR RESERVE MATERIEL (WRM) MANAGEMENT

TR: AFPD 25-1; AFI 25-101; AFI 10-401; AFI 10-403; AFI

10-404; AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 1 &

Vol 2; DODD 3110.6

2.10.1

Explain the purpose of the WRM program

2.10.2

Explain the roles and responsibilities of WRM management

entities (base, MAJCOM, & enterprise level)

2.10.3

Explain budgetary process and procedures of WRM funding

2.10.4

Identify types and categories of WRM

2.10.5

Analyze War Plans Additive Requirements Report (WPARR)

2.10.6

Analyze War Consumables Distribution Objective (WCDO)

2.10.7

Analyze Inventory Management Plan (IMP)

2.10.8

Identify WRM requirements on the Vehicle Authorization List

(VAL)

2.10.9

Analyze Wartime Aircraft Activity Report (WAAR) extract

2.10.10

Explain WRM peace time use request purpose and process

2.11

SUPPORT AGREEMENTS TR: AFI 25-201; AFI 25-301

2.11.1

Explain the types, purpose, and milestones of support agreements

2.11.2

Explain the roles and responsibilities of the Support Agreement

Manager

2.11.3

Explain the roles and responsibilities of the Functional Area

Agreement Coordinator

2.11.4

Explain the purpose of an Acquisition Cross-Servicing

Agreement (ACSA)

2.11.5

Explain the Functional Area Responsibilities and Authorities

associated with ACSA

26

2.11.6

Attend and Complete Contingency Wartime Planners Course

(CWPC)

2.11.7

Attend and complete the Installation Deployment Officer (IDO)

Course

2.12

FACILITIES TR: AFMAN 32-1084

2.12.1

Explain Logistics Plans infrastructure for Military Construction

(MILCON) and justification

27

Chart 7. Transportation (Ground) Training Matrix

Transportation (Ground)

Operations Officer Signature/Date Completed

Note: To complete the Ground Transportation Training Matrix, the trainee MUST have ALL

processes/knowledge areas signed off.

Note: If a process/knowledge area is not available at a particular location, trainers may line through and initial

the process/knowledge area. This action will waive the requirement for that specific process; however,

commanders must review/verify each lined through process/knowledge area prior to submitting an AF Form

2096. Once a waived process becomes available due to PCS or other change, commanders should ensure the

individual is properly trained on that requirement.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

3.0

TRAFFIC MANAGEMENT TR: DoD 4140.1-R; AFMAN

24-204; AFPD 24-2; DOD 4140.65; AFI 24-238; AFMAN

24-206; Pax: DoDD 4500.56; AFPD 24-1; DoDI 4500.43;

DoD 4515.13

3.1

CARGO MOVEMENT GENERAL

TR: DOD 4500.9R Part II; AFI 10-401; AFI 24-203; AFI

91-302; AFPAM 24-237; AFJMAN 24-206; AFMAN 24-

204; AFOSH STD 91-501; MIL-STD 2073; MIL-STD 129;

TO 00-85 series; Carriers’ Classification and Rate Tariffs;

NMFC; UFC; Channel Sequence Listing

3.1.1

Identify the capabilities of Transportation (Ground) Unit Type

Codes (UTC)

3.1.2

Identify the importance of the Transportation Discrepancy

Reports (TDR), Report of Shipment (REPSHIP) and the

personal property discrepancy reports

3.1.3

Explain the Uniform Materiel Movement and Issue Priority

System (UMMIPS), Required Delivery Date (RDD), and

Project Codes, and TAC Codes

3.1.4

Identify the various modes of shipment

3.1.5

Explain Secure Holding Areas

3.1.6

Identify the methods of preparing, packing and crating cargo

3.1.7

Explain the shipping and receiving process

28

3.1.8

Identify the importance of controlling accountable forms

3.1.9

Explain the importance of controlling classified, hazardous and

NWRM cargo

3.1.10

Distinguish the importance of NWRM cargo movement policies

and procedures

3.1.11

Explain the importance of In-transit Visibility (ITV) and the

Integrated Development Environment/Global Transportation

Network Convergence (IGC)/Enterprise Solution-Supply (ESS)

3.1.12

Explain the importance of the Cargo Movement Operations

System (CMOS)

3.2

PERSONAL PROPERTY MOVEMENT

ARRANGEMENTS

TR: JFTR (Vol 1) JTR (Vol 2); Air Force

Supplement/JFTR Vol 1 and JTR Vol 2; DoD 4500-9R; Part

IV; PPCIG (Vols 1 and 2); DD FORM 1797; DoD 4500.9R

Part IV & V; AFPD 24-4; Personal Property Rate

Solicitation; SDDC Volume Rate; Defense Table of Official

Distances (DTOD); AFI 64-102; TOPS Manual; MIL-STD

129

3.2.1

Explain how personal property movement entitlements are

determined and the difference between household goods,

unaccompanied baggage, professional equipment and storage

3.2.2

Identify privately owned vehicle shipping entitlements

3.2.3

Identify the rules for shipping privately-owned firearms

3.2.4

Explain the process for individuals to perform a personally

procured move

3.2.5

Explain your role in regards to the movement of deceased

personnel’s personal property (BLUE BARK)

3.2.6

Explain the function of the Defense Personal Property System

(DPS) and how it applies to customers

3.2.7

Explain the personal property shipping procedures to include

the relationship between the carrier and the service,

loading/receiving process, inspections and movement

entitlements

3.2.8

Identify proper use of the Personal Property Consignment and

Info Guide World Wide (PPCIGW)

3.2.9

Explain the Joint Personal Property Shipping Office (JPPSO)

functions

3.3

PASSENGER TRAVEL

TR: DoD 4500.9R; JFTR (Vol 1); JTR (Vol 1 & 2); AFI 24-

101; AFI 24-501; Defense Table of Distances (DTOD);

MTMC Volume Rate Printout (VRP); Domestic &

International Rate Solicitation Guides; AFI 51-502; AFI 24-

201; AFMAN 24-204; AFI 24-203; MIL-STD 129; TO 00-85

29

series; Foreign Clearance Guide; AFI 10-403; AFI 36-2101;

AFI 38-201; AFI 90-201

3.3.1

Explain passenger movement entitlements and responsibilities

for passenger travel

3.3.2

Identify the mode(s), routing, and cost for passenger travel

3.3.3

Identify the functions of the Commercial Travel Office (CTO)

3.3.4

Explain the movement process for human remains

3.3.5

Explain the rules regarding emergency leave travel

3.3.6

Identify the difference between Centrally Billed Account and

Individually Billed Account

3.4

DEPLOYMENT OPERATIONS

TR: AFMAN 10-401; AFI 10-403; DoD 4500.9R; AFI 10-

201; AFI 36-6023

3.4.1

Explain the role of Traffic Management in the deployment

process

3.4.2

Identify the importance of deployment work centers and

deployment training

3.5

VEHICLE OPERATIONS

TR: AFI 10-403; AFI 24-301; SFI 12-213; AFI 24-306;

AFOSH 91-100

3.5.1

Identify vehicle operations responsibilities during mobility

operations to include deployment, reception, operations and

employment

3.5.2

Identify the functions of Documented Cargo Section

3.5.3

Discuss the authorized use of Government Motor Vehicles

3.5.4

Explain the Government Motor Vehicle Misuse Process

3.5.5

Explain the policies and procedures to operate vehicles in both

peacetime and contingency environments

3.5.6

Identify licensing procedures

3.5.7

Identify dispatch procedures

3.5.8

Identify Training and Validation procedures

3.6

FACILITIES TR: AFMAN 32-1084

3.6.1

Explain the Transportation (Ground) infrastructure for Military

Construction (MILCON) and justification

30

Chart 8. Transportation (Air) Training Matrix

Transportation (Air)

Operations Officer Signature/Date Completed

Note: To complete the Air Transportation Training Matrix, the trainee MUST have ALL

processes/knowledge areas signed off.

Note: If a process/knowledge area is not available at a particular location, trainers may line through and

initial the process/knowledge area. This action will waive the requirement for that specific process;

however, commanders must review/verify each lined through process/knowledge area prior to submitting an

AF Form 2096. Once a waived process becomes available due to PCS or other change, commanders should

ensure the individual is properly trained on that requirement.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

4.0

ORGANIZATION AND MISSION OF MILITARY

AIRLIFT SYSTEMS

TR: DTR 4500.9-R; AMCI 24-101; AFI 24-114; AFI 10-

401; AFI 10-403

4.0.1

Identify the organization and mission of the commands within

the DoD airlift system

4.0.2

Identify the types and descriptions of organic and commercial

transport aircraft and associated capabilities

4.0.3

Explain the mission and functions of the Aerial Port Squadron

and Air Mobility Squadron

4.0.4

Identify the capabilities of Transportation (Air) Unit Type

Codes (UTC)

4.0.5

Identify the types and descriptions of material handling

equipment and associated capabilities

4.0.6

Explain the concept and process for managing Transportation

Working Capital Funds (TWCF)

4.1

PASSENGER SERVICE OPERATIONS

TR: DTR 4500.9-R, 4515.13; AMCI 24-101 Volumes 14 &

15; AFI 24-101

4.1.1

Explain customer relations and DV procedures

4.1.2

Explain how to determine travel eligibility

4.1.3

Explain how to manage standby listings

31

4.1.4

Explain delayed or diverted space required passengers policies

4.1.5

Explain travel restrictions and border clearance requirements

4.1.6

Identify funds control procedures

4.1.7

Explain Space Available (SA) and Space Required (SR)

passengers policies and procedures

4.1.8

Explain Passenger Terminal Security and Screening

4.1.9

Discuss Non-combatant Evacuation Operation (both

originating and reception)

4.2

FLEET SERVICES

TR: AMCI 24-101;Volumes 10 & 14; Appropriate Aircraft

-9’s and -1’s

4.2.1

Identify the role and functions of Fleet Services in Aerial Port

operations

4.2.2

Identify health factors/threats during fleet services operations

4.3

AIR TERMINAL OPERATIONS

TR: AMCI 24-101 Volume 9

4.3.1

Discuss the roles and responsibilities of the Air Terminal

Operations Center

4.3.2

Conduct ramp control functions

4.3.3

Discuss the concept of capability forecasting

4.3.4

Explain the role of Customer Service Branch/Airlift Clearance

Authority

4.3.5

Explain the QAE process for contract commercial aircraft

documentation

4.3.6

Explain how to process and coordinate Human Remains at

origin, en route and arrival stations

4.4

AIR CARGO PROCEDURES

TR: DODR 4500.32, 4500.9; AFJMAN 24-204; AFPD 24-2;

AMCI 24-101 Volume 11; Mil Std 129; CFR 49; AMCI

24.101 Volume 9; AFI 24-201

4.4.1

Explain how to process originating and terminating cargo

4.4.2

Explain how to process originating and terminating mail

4.4.3

Explain the concepts of load planning

4.4.4

Explain the tradeoff between velocity and maximum aircraft

utilization

32

4.4.5

Conduct palletization procedures

4.4.6

Discuss special handling cargo procedures

4.4.7

Identify how to expedite priority shipments

4.4.8

Explain hazardous/explosive materials movement and

compatibility

4.5

RAMP OPERATIONS

TR: DTR 4500.9-R; AFPD 24-2; TO 00-25-172; AMCI 24-

101

4.5.1

Explain procedures for loading and offloading aircraft

4.5.2

Identify the role of the Aerial Port Expeditor Program (APEX)

4.5.3

Explain Engine Running On and Off loading (ERO)

procedures

4.5.4

Discuss Risk Management (RM) specific to ramp operations

4.6

MOBILITY OPERATIONS

TR: DTR 4500.9-R; AFI 10-403; AFI 10-401; AMCI 24-

101

4.6.1

Explain deployment work centers and their respective missions

4.6.2

Explain the Joint Inspection (JI) process

4.6.3

Identify the roles and missions of Contingency Response

Wings and Groups, Combat Mobility Element

(CRW/CRG/CME)

4.7

AUTOMATED INFORMATION SYSTEMS TR:

Applicable handbooks and system guides

4.7.1

Explain the Integrated Development Environment/Global

Transportation Network Convergence (IGC)

4.7.2

Identify the Global Decision Support System (GDSS)

4.7.3

Explain Global Air Transportation Execution System (GATES)

and Cargo Movement Operating System (CMOS)

4.7.4

Explain the Integrated Computerized Deployment System

(ICODES)

4.7.5

Explain Total Asset Visibility (TAV)

4.8

FACILITIES: AFMAN 32-1084

4.8.1

Explain the Transportation (Air) infrastructure for Military

Construction (MILCON) and justification

33

Chart 9. Supply Training Matrix

Supply

Operations Officer Signature/Date Completed

Note: To complete the Supply Training Matrix, the trainee MUST have ALL processes/knowledge areas

signed off.

Note: If a process/knowledge area is not available at a particular location, trainers may line through and

initial the process/knowledge area. This action will waive the requirement for that specific process;

however, commanders must review/verify each lined through process/knowledge area prior to submitting an

AF Form 2096. Once a waived process becomes available due to PCS or other change, commanders should

ensure the individual is properly trained on that requirement.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

5.0

Explain the Materiel Management Flight Organizational

Structure

5.0.1

Identify the capabilities of Supply Unit Type Codes (UTC)

5.1

ASSET MANAGEMENT TR: AFI 23-101; AFMAN 23-

122; AFH 23-123 Vol 2 Pt 1

5.1.1

Explain the Base Supply Management Report ( M-32)

5.2

AIRCRAFT PARTS STORE TR: See references below

within specific process/procedure

5.2.1

Analyze the decentralized concept of the Aircraft Parts

Store (APS)

5.2.2

Explain the roles and responsibilities of APS

5.2.3

Explain the Care of Stock in Storage (COSIS) principles

5.2.4

Explain the relationship and parts request process with

flightline maintenance organizations

5.2.5

Analyze the Readiness Spares Packages (RSP) concept and

management

5.2.6

Analyze the Wartime Mobilization Plan (WMP) Parts 3

and 5

5.2.7

Explain the relationship between WMP (Parts 3 and 5) and

RSPs

34

5.2.8

Explain the types/differences between RSPs and Mission

Support Kits (MSK)

5.2.9

Analyze the difference between detailed-managed items

and Peacetime Operating Stock (POS)

5.2.10

Analyze the RSP/MSK Listings and utilization of products

5.2.11

Analyze the Base-Level Review Process

5.2.12

Explain the funding process for RSP

5.2.13

Explain the RSP Authorization Reconciliation process

5.2.14

Explain differences between RSP transfer and deployment

status

5.2.15

Explain Aircraft Sustainability Model (ASM) Assessments

5.2.16

Explain the AF Form 2005

5.3

BENCH STOCK

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 1 &

Vol 2

5.3.1

Analyze the bench stock management concept and purpose

5.3.2

Analyze the Master Bench Stock List (S04)

5.3.3

Analyze the Bench Stock Review List (M04)

5.4

MISSION CAPABLE (MICAP) PROCESSES

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 1 &

Vol 2

5.4.1

Analyze the MICAP concept and the varying levels of

responsibilities

5.4.2

Identify the responsibilities of Base, Supply Chain

Operations Wing (SCOW), Supply Chain Management

Wing (SCMW), Air Force Sustainment Center (AFSC),

Depot, and MAJCOM in the MICAP process

5.4.3

Explain the importance of the Aerospace Maintenance and

Regeneration Group (AMARG)

5.4.4

Explain the MICAP verification process

5.4.5

Analyze cause & delete codes

5.4.6

Analyze ES-S MICAP & AWP Reports

35

5.5

STOCK CONTROL PROCESSES

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 1 &

Vol 2

5.5.1

Explain the purpose for stock management

5.5.2

Identify the different stockage policies and levels (demand

based and non-demand based)

5.5.3

Explain inventory levels (Adjusted Stock Levels, MRSP,

CRSP, CHPMSK)

5.5.4

Analyze Readiness Base Leveling (RBL) Proactive

Demand Leveling (PDL) and Customer Oriented Leveling

Technique (COLT) concepts

5.5.5

Conduct a Aircraft Sustainability Model (ASM)

5.5.6

Identify MILSTRIP procedures

5.5.7

Explain the Uniform Materiel Movement and Issue Priority

System (UMMIPS)

5.5.8

Explain the Force Activity Designator (FAD) concept

5.5.9

Explain a Due-out validation

5.5.10

Identify the Air Force retention/excess polices

5.5.11

Explain the purpose of Transaction Identification Codes

5.5.12

Understand how requirements are funded

5.5.13

Explain the process of requesting Supply Assistance

Request and Supply Discrepancy Report

5.5.14

Explain Local Purchase policies and procedures

5.6

EQUIPMENT MANAGEMENT PROCESSES

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 2 Pt

1

5.6.1

Identify the Air Force Equipment Management System

(AFEMS)

5.6.2

Identify the equipment management Allowance Standard

concept

5.6.3

Explain the accountability requirements for Non-

Equipment Authorized In-use Detail equipment authorized

inventory data

5.6.4

Identify the Organizational Visibility List (R-15)

5.6.5

Identify the process involved in requesting equipment

36

5.6.6

Identify the establishment of In-use details

5.6.7

Identify the various EAID products and listings to include

Q09 and Q10 listings

5.6.8

Identify the purpose of the R14 - Custodian

authorization/custody receipt listing (CA&CRL)

5.6.9

Identify the purpose of Special Purpose Recoverable

Authorized Maintenance (SPRAM) and the R25 SPRAM

listing

5.7

REPAIR CYCLE MANAGEMENT PROCESSES

TR: AFI 23-101; AFMAN 23-122 Sec 4C; TOs 00-20-3;

00-35D-54

5.7.1

Discuss the Due-In From Maintenance (DIFM) process

5.7.2

Analyze the repair cycle asset management listing (D23)

5.7.3

Explain the Repair Network Enhancement Program

5.7.4

Identify impacts of Turnaround Action (TRN)

5.7.5

Analyze the Awaiting Parts (AWP) listing (D19)

5.7.6

Explain the concept of time change items

5.7.7

Explain the Time Compliance Technical Orders (TCTO)

process

5.7.8

Explain the concept of Depot Level Reparables (DLR)

5.7.9

Explain Supply points and how they are managed

5.7.10

Identify Supply point detail records

5.7.11

Explain the repair cycle data list Q04

5.7.12

Describe the Repair Network and the collaborative

relationship between the Node Manager, Repair Network

Manager, and other supply entities for repair constraint

resolution

5.7.13

Explain Supply Condition Codes

5.8

ISSUE PROCEDURES

TR: AFI 23-101; AFMAN 23-122 Ch 5, 9, 10; AFH 23-

123 Vol 1 & Vol 2 Pt 1 AFR 0-2;TOs 0-1-01, 00-5-1;

Illustrated Parts Breakdown (IPB); FEDLOG; D043

5.8.1

Explain the issue process

37

5.9

RESEARCH/RECORDS MAINTENANCE

PROCEDURES

TR: AFMAN 23-122

5.9.1

Identify the manual research process

5.9.2

Identify the parts of national stock number

5.9.3

Identify the various materiel management research systems

to include ES-S FEDMALL, FEDLOG, D043

5.9.4

Analyze an Item record

5.9.5

Explain Expendability, Recoverability, Reparability, and

Cost (ERRC) codes

5.9.6

Identify Interchangeability and Substitution Group (I&SG)

records

5.10

TURN-IN PROCEDURES TR: AFMAN 23-122; AFI

23-101, TO00-35D-54

5.10.1

Explain the turn-in process for Consumables/expendables

5.10.2

Explain the turn-in process for Repair cycle

5.10.3

Explain the turn-in process for Equipment

5.10.4

Explain the turn-in process for Exception processing

5.10.5

Explain the turn-in process for Found on Base

5.10.6

Explain the turn-in process for Hazardous material

5.10.7

Explain the turn-in process for Engineering Investigation

(EI)/PQDR

5.10.8

Explain the turn-in process for In-check property

5.10.9

Explain the turn-in process for Inspect property for

assignment of condition code

5.10.10

Explain the turn-in process for a DIFM, consumable, etc.

item

5.11

INQUIRIES

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 2 Pt

1

5.11.1

Explain a Detail record

5.11.2

Analyze the consolidated transaction history (CTH)

5.11.3

Explain the Repair cycle record

38

5.11.4

Explain the Requirements computation

5.11.5

Explain the capabilities of LIMS-EV

5.12

INSPECTION PROCESSES

TR: AFMAN 23-122

5.12.1

Identify the different Condition tags/labels

5.12.2

Explain the different Condition codes

5.12.3

Explain Identity changes

5.12.4

Explain inspection requirements for various commodities

5.12.5

Explain Shelf life management to include bench stock

5.12.6

Explain HAZMAT management and storage procedures

5.12.7

Explain the Functional check process

5.12.8

Explain the management of Electrostatic sensitive

devices/electrostatic discharge (ESD) items

5.12.9

Explain suspect/unsuitable materiel management

5.13

STORAGE AND DISTRIBUTION PROCESSES

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 2 Pt

1

5.13.1

Explain the warehouse storage layout

5.13.2

Explain the general storage principles

5.13.3

Conduct a warehouse pull

5.13.4

Explain the purpose of the Daily Document Register (D04)

5.13.5

Explain the steps to pull, distribute, and issue property

5.13.6

Explain the difference between a Due-In and Due-Out

5.13.7

Explain how and why a shipment can occur

5.13.8

Explain the process of warehouse location validation

5.13.9

Explain the processing of warehouse refusals

39

5.13.10

Explain the organizational refusal procedures

5.13.11

Explain the controlled material storage requirements

5.13.12

Explain the use of the classified receipt list

5.13.13

Explain the relationship between Materiel Management and

Documented Cargo

5.14

INVENTORY PROCEDURES

TR: AFMAN 23-122

5.14.1

Identify various types of non-NWRM inventories and their

purposes

5.14.2

Develop an inventory schedule

5.14.3

Conduct an inventory

5.14.4

Discuss Nuclear Weapons Related Materiel (NWRM)

Accountability & Positive Inventory Control (PIC) as

detailed in AFI 20-110

5.14.5

Explain the reverse posts process and the impact on

inventories and accountable records

5.14.6

Analyze the consolidated inventory adjustment document

register (M10)

5.15

DOCUMENT CONTROL

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 1 &

Vol 2 Pt 1

5.15.1

Identify what constitutes source documents

5.15.2

Identify the steps involved in document disposition

5.15.3

Explain the management and resolution of delinquent

documents

5.15.4

Explain the Tracer Action Reports and Shipping

Discrepancy Reports

5.16

CONSOLIDATED SUSTAINMENT ACTIVITY

GROUP – SUPPLY (CSAG-S) TR: AFI 23-101;

AFMAN 23-122; AFH 23-123 Vol 1 & Vol 2 Pt 1

5.16.1

Explain the CSAG-S funding process

5.17

REJECT/MANAGEMENT NOTICE PROGRAM

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 2 Pt

2 Ch 7

5.17.1

Identify responsibilities in the reject management program

5.17.2

Explain the reject research processes

40

5.17.3

Explain the management notice research process

5.17.4

Explain the steps involved in resolving rejects

5.18

POST-POST PROCESSING

TR: AFMAN 23-122

5.18.1

Explain the concept of Post-Post Processing

5.19

PROCEDURES AND ANALYSIS PROCESSES

5.19.1

Explain the functions of the Inspection Section

5.19.2

Explain the Care of Supplies in Storage (COSIS)

5.19.3

Explain how to conduct internal Annual Inspections

5.19.4

Identify the importance of customer support visits

5.19.5

Identify the management reports and listings used to assess

the health of a Supply Account

5.20

DECENTRALIZED MAINTENANCE SUPPORT

(DMS) TR: AFMAN 21-101; AFI 23-101

5.20.1

Explain the roles and responsibilities of (DMS)

5.20.2

Identify the relations between DMS/MXG and Customer

Support Liaison Element

5.21

GENERAL TASKS AND KNOWLEDGE

TR: AFI 23-101; AFMAN 23-122; AFH 23-123 Vol 1 &

Vol 2, AFR 40O-54, AFJMAN 23-215, AFI 23-111; AFI

91-301, DoD 4145.19-R-1; 40 CFG261; FED Standard

313; AF Internal Procedures for using the GPC

5.21.1

Explain the Reports of Survey process

5.22

FACILITIES TR: AFMAN 32-1084

5.22.1

Explain the Transportation (Ground) infrastructure for

Military Construction (MILCON) and justification

41

Chart 10. Vehicle Management Training Matrix

Vehicle Management

Operations Officer Signature/Date Completed

Note: To complete Vehicle Management Training Matrix, the trainee MUST have ALL

processes/knowledge areas signed off.

Note: If a process/knowledge area is not available at a particular location, trainers may line through and

initial the process/knowledge area. This action will waive the requirement for that specific process;

however, commanders must review/verify each lined through process/knowledge area prior to submitting an

AF Form 2096. Once a waived process becomes available due to PCS or other change, commanders should

ensure the individual is properly trained on that requirement.

Knowledge

Trainee

Initials

Certifiers

Initials

Date

6.0

VEHICLE MANAGEMENT

TR: AFI 10-401; AFI 24-302; TO 36-1-191

6.0.1

Explain the functions of vehicle management

6.0.2

Identify the capabilities of Vehicle Management Unit Type

Codes (UTC)

6.0.3

Explain the mobile maintenance processes and procedures

6.0.4

Explain managements roles and responsibilities in fleet

management

6.0.5

Analyze the Critical Vehicles Listing

6.0.6

Discuss the purpose of Mission Essential Levels

6.0.7

Explain the Mission Capable rate

6.0.8

Analyze the Vehicle Authorization Listing

6.0.9

Explain management’s role in regards to the Vehicle

Validation Visit process

6.0.10

Explain the vehicle authorization establishment process

6.0.11

Explain the process and procedures for managing vehicles

identified as Nuclear Certified Equipment

6.0.12

Discuss the vehicle equivalents and vehicle management

funding process

42

6.0.13

Explain the Vehicle Management systems to include DPAS,

LIMS-EV-VV etc.

6.0.14

Explain how vehicles are tasked and prepared for

deployment

6.1

FLEET MANAGEMENT AND ANALYSIS ELEMENT